Mounting and splicing joint of large-section circular steel tube and operation method of mounting and splicing joint

A round steel pipe and large-section technology, which is applied to the installation and splicing joints of large-section round steel pipes, can solve the problems of high requirements for the welding seam of the lug plate, easy deformation, and high technical level requirements, so as to reduce the amount of welding works and ensure the installation accuracy. , to ensure the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

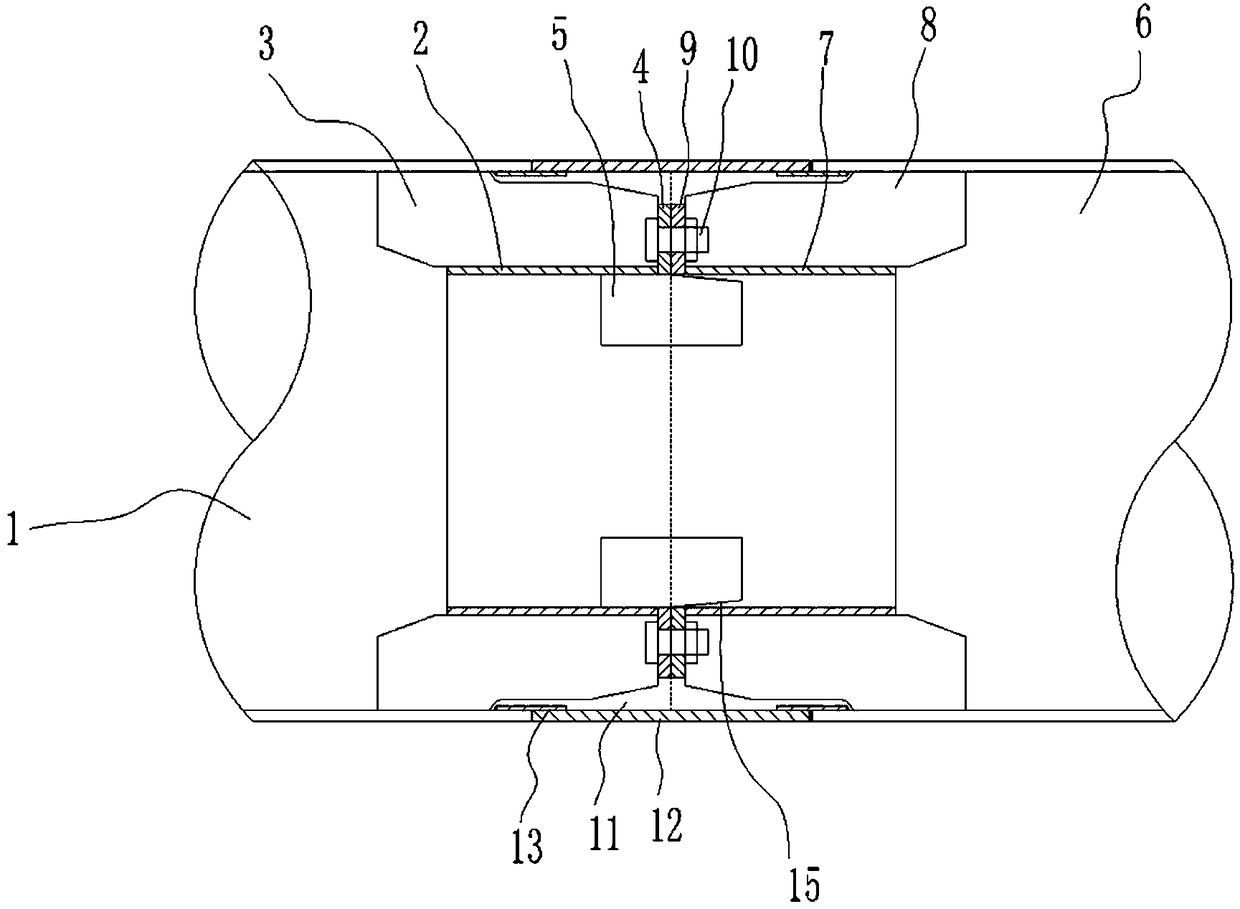

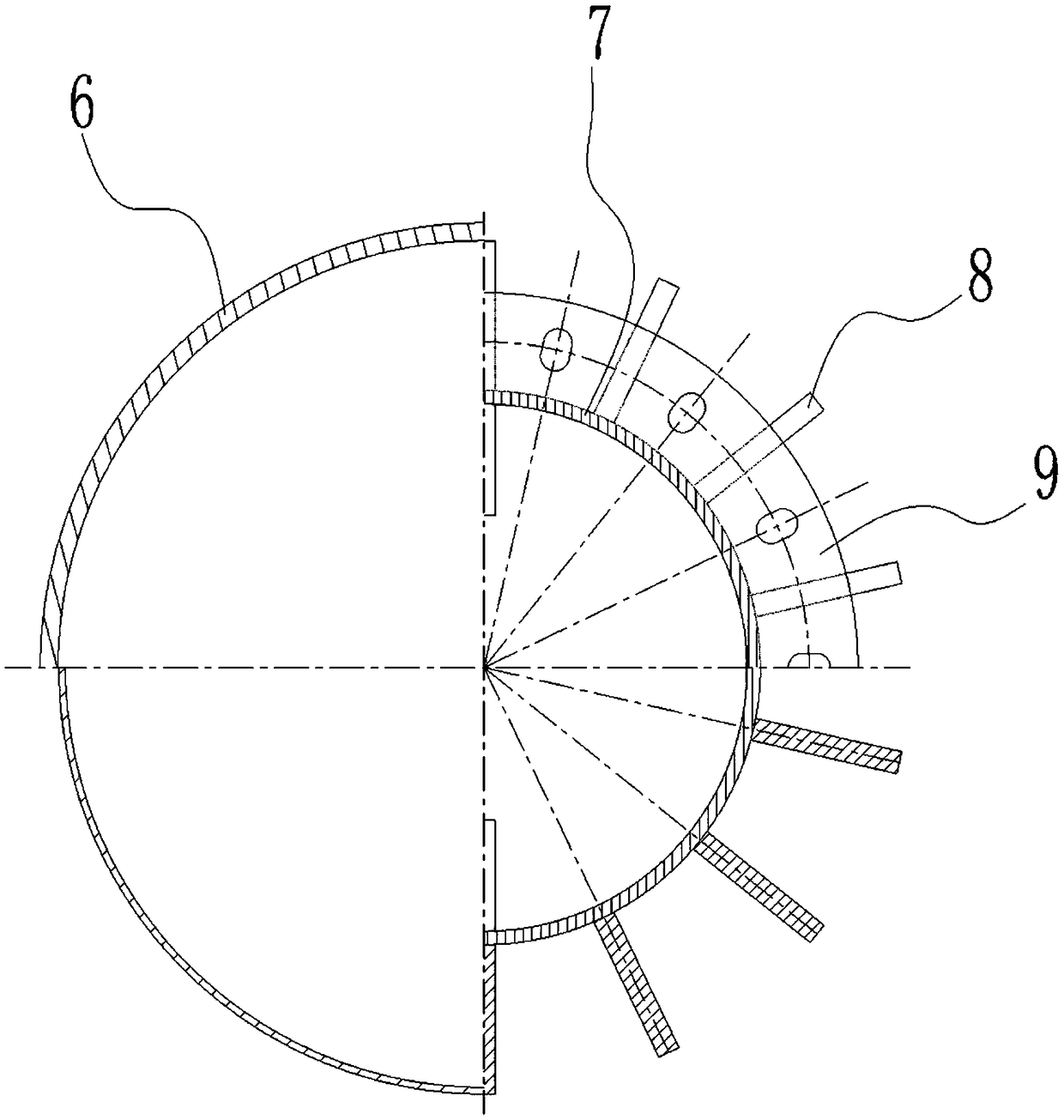

[0023] Embodiment 1: As shown in the figure, an installation splicing node of a large cross-section round steel pipe includes a male connection end and a female connection end, and the male connection end and the female connection end are distributed in a spliced shape;

[0024] The connecting end of the male head includes a male steel pipe 1 and a left inner support 2, the left inner support 2 extends out of the male steel pipe 1 to the right, and the male steel pipe 1 and the left inner support 2 pass through A number of left support plates 3 distributed at intervals are fixed, and the outer wall of the left support plate 3 is provided with a left flange 4, and the bottom of the left flange 4 and the inner wall of the left inner support 2 are distributed on the same horizontal plane. , the inner wall of the left inner support 2 is provided with a number of in-position guide tenons 5;

[0025] The female connecting end includes a female steel pipe 6 and a right inner suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com