An ultra-wide cross-sectional structure suitable for a through steel truss girder of a double-track railway

A steel truss girder and cross-section technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large deflection of beams, increased cost, increased steel consumption and self-weight of beams, etc., to reduce self-weight, facilitate manufacturing, save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

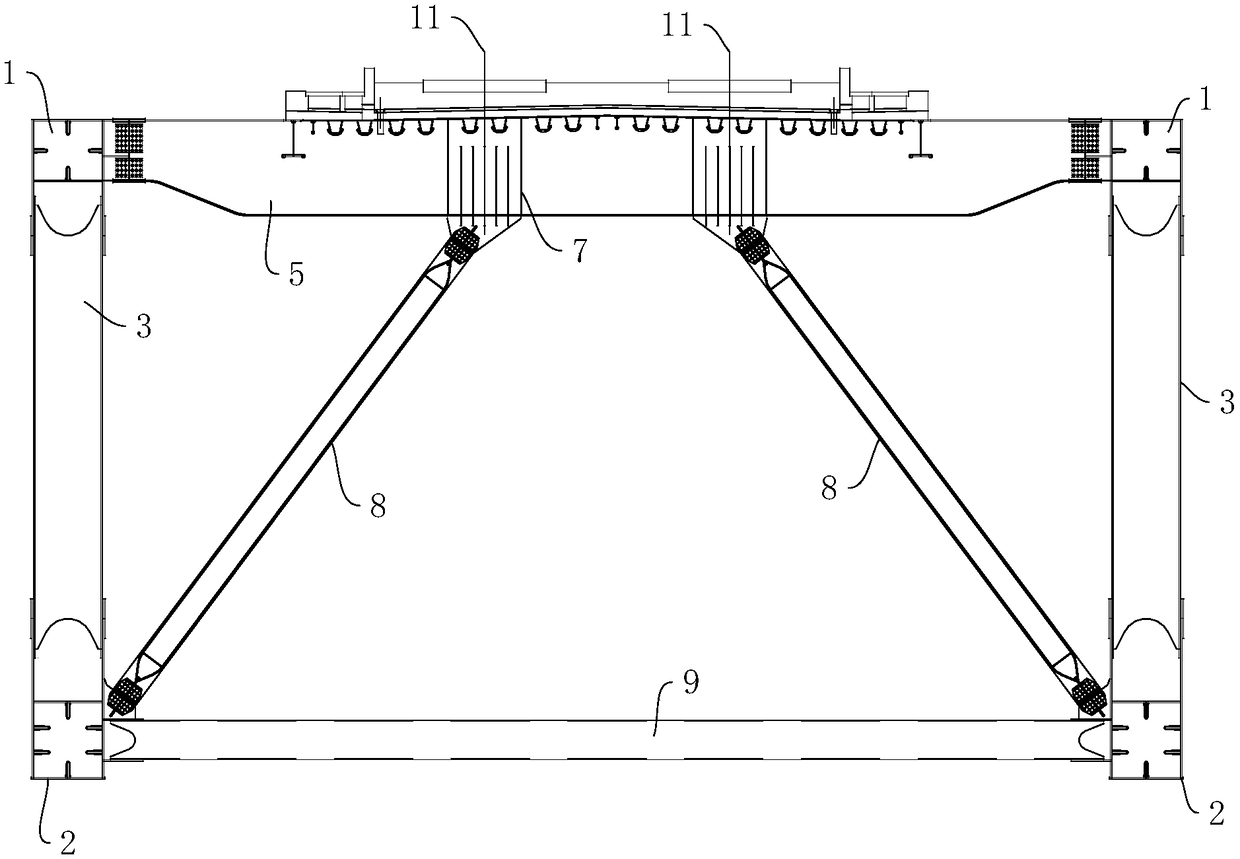

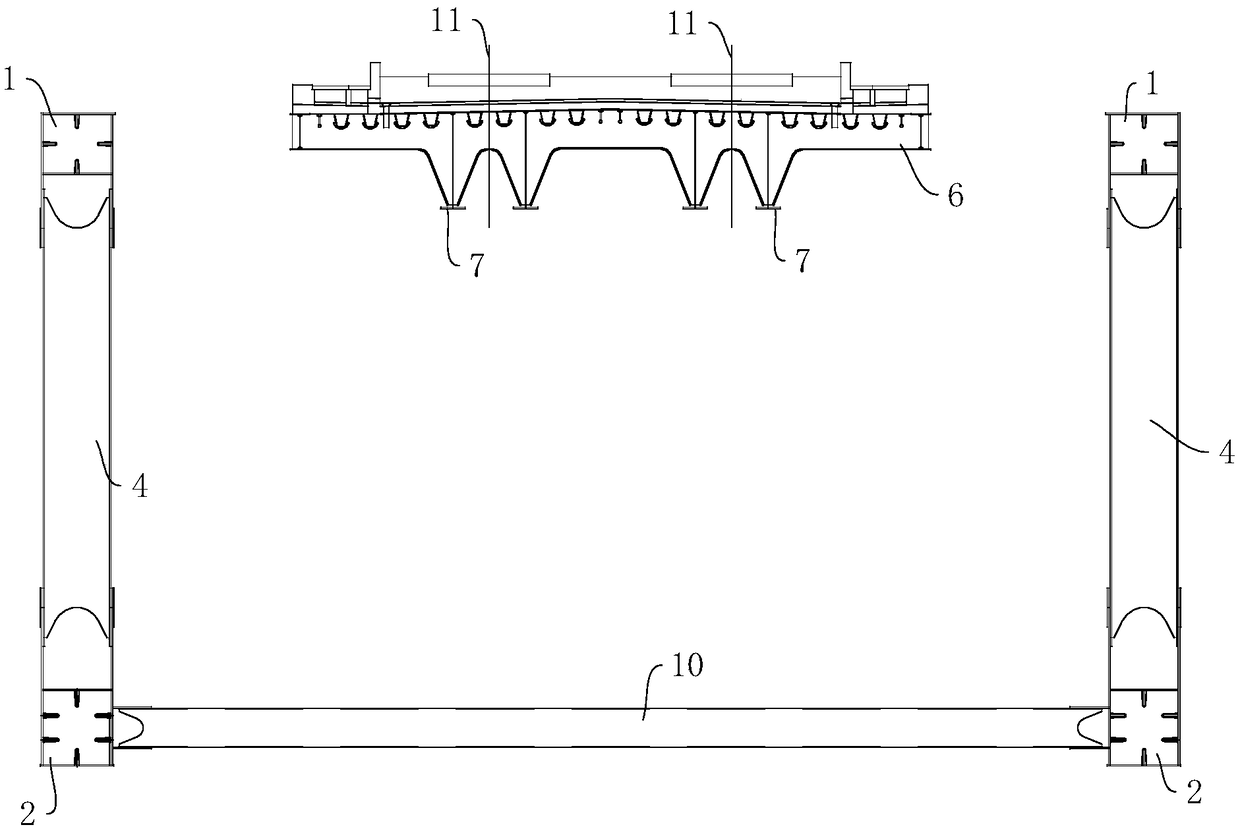

[0025] Such as Figure 1-2 An ultra-wide cross-sectional structure suitable for double-track railway overhead steel truss girders is shown, including steel truss girders, including cross girders 5 and transverse bars 8 for supporting lines, and cross girders 5 are located at the top of steel truss girders, The transverse slanting bar 8 is located below the beam 5, one end of the transverse slanting bar 8 is connected to the middle of the beam 5, the other end of the transverse slanting bar 8 is connected to the steel truss girder, and the transverse slanting bar 8 is arranged obliquely on the line cross section.

[0026] The ultra-wide cross-section structure of the present application greatly reduces the vertical deflection of the beam 5 under the action of dead load and live load due to the vertical support effect of the transverse diagonal bar 8 on the beam 5, and effectively reduces the width of the ultra-wide truss bridge deck. The height of the crossbeam 5 is tied, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com