Assembled truss formwork support

A formwork support and assembly technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of web eccentricity and large gap between assembly nodes , Large vertical deflection, low truss stiffness, etc., to reduce the influence of web member eccentricity and assembly gap, reduce vertical deflection, and ensure the effect of truss stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

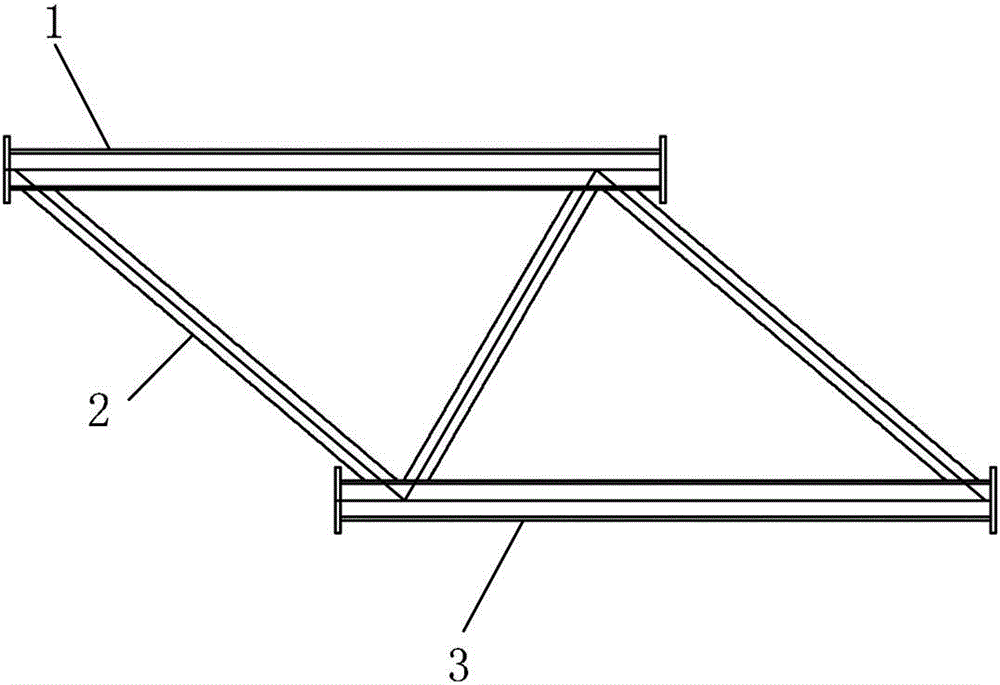

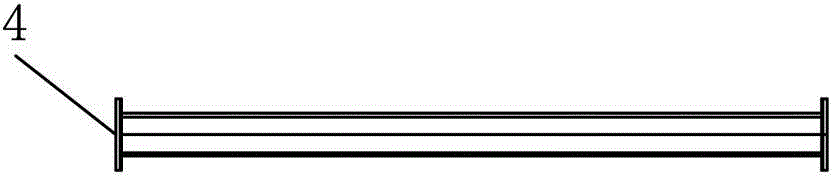

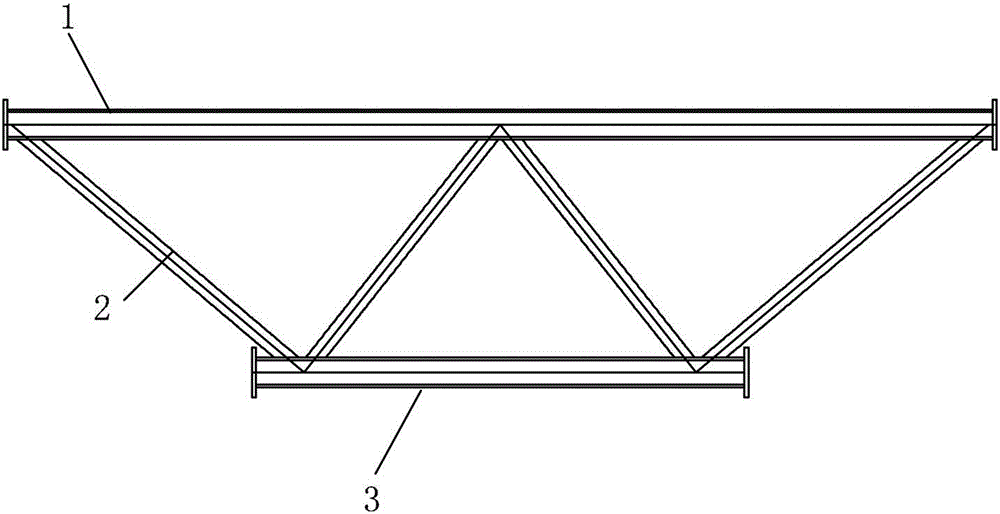

[0031] As shown in the figure: 1-8: the truss is changed from the original single-bar assembly to the shaped truss unit with end plates connected by bolts 5 to connect the joints, 1-meter single-bar unit 21, type I truss unit (1 meter) 20 and Type II truss units (2m) 18, end rods 19, the upper and lower chords 1, 3 of each shaped truss unit are connected to the diagonal support 2 by welding, the ends are end plates 4 with bolt holes, and the truss units are connected by bolts 5, After assembly, a truss with a span of 6 meters can be formed, and a vertical support 7 is added to the end rods 19 at both ends of the truss to form an assembled truss formwork support; the truss unit node at the end of the truss with different spans is A node 10, and the vertical support 7 The connection with the end bar is the B node 9, and when the distance from the A node to the B node is 150mm, another vertical support is added at the A node 10.

[0032] The shaped truss unit includes Type I trus...

Embodiment 2

[0039] The difference from Embodiment 1 is that a type II truss unit (2 meters) and end rods form a truss with a span of 4M.

Embodiment 3

[0041] The difference from Embodiment 1 is that a type II truss unit (2 meters), a type I truss unit (1 meter) and end rods form a truss with a span of 5M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com