Storage tank

A storage tank and cylinder technology, applied in the field of refrigerated liquefied gas, can solve the problems of instability, increased deflection and insufficient strength of the tank, and achieve the effects of improving economy, strong bearing capacity and reducing vertical deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

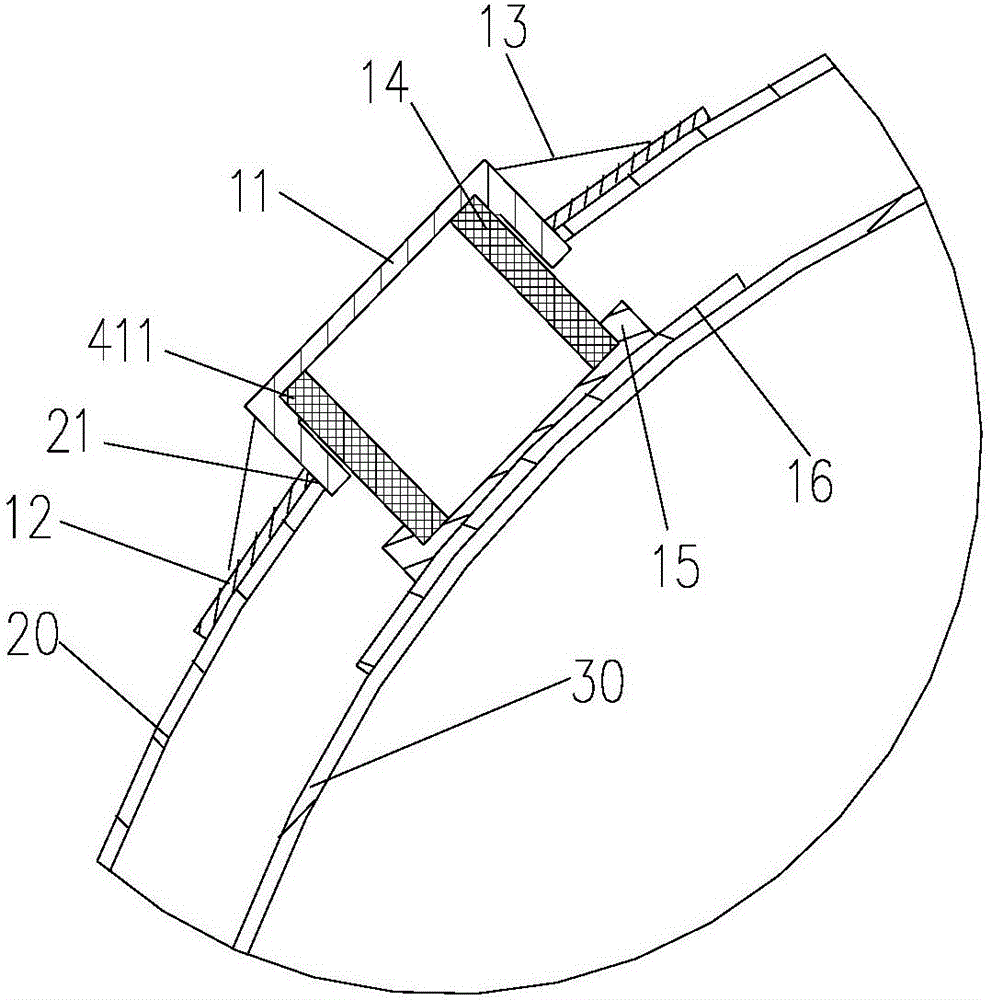

[0047] The embodiment of the present application provides a storage tank, which solves the problems in the prior art due to the large distance between the fixed end and the sliding end of the glass fiber reinforced plastic support device, resulting in increased deflection, prone to instability of the tank, and the tank has a large volume and relatively large loading medium. For a long time, there is a technical problem of insufficient strength.

[0048] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

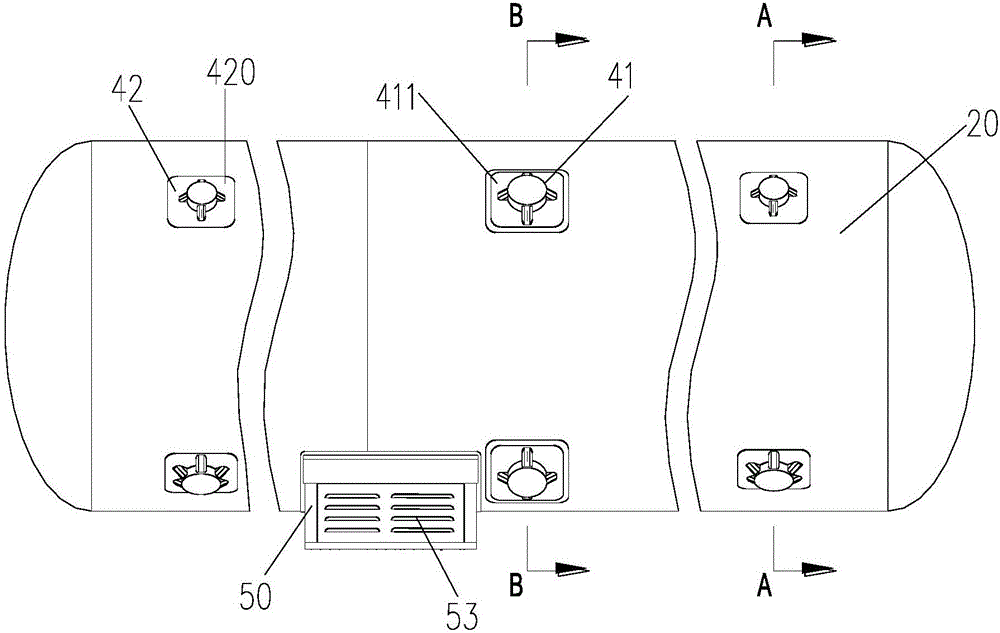

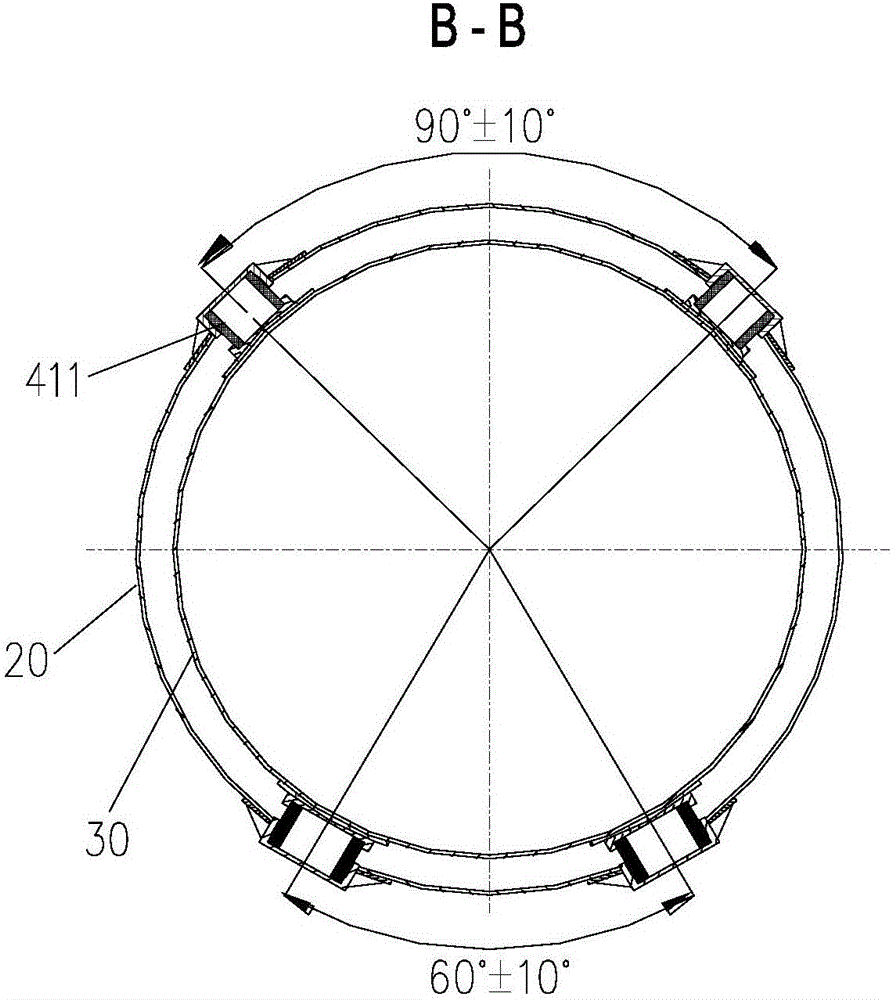

[0049]In this application, the operating system is arranged under the middle part of the storage tank, the fixed support is arranged at the middle part of the tank body, and the sliding supports are arranged at both ends of the tank body. The valve box is fixed under the middle of the tank body, making full use of the lower space of the storage tank body for layout and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com