Cloth boundary recognition method for sewing machine and sensor and identification device thereof

A boundary recognition and sewing machine technology, applied in sewing equipment, sewing machine components, cloth feeding mechanisms, etc., can solve the problems of large data processing volume, slow response speed, inconvenient installation, etc., to improve recognition accuracy, improve stability, avoid The effect of false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with the aid of the drawings.

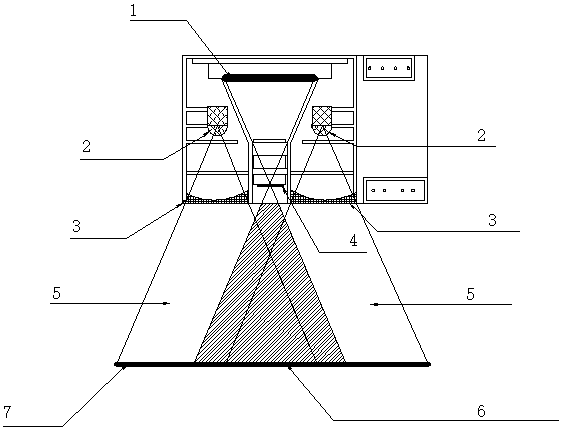

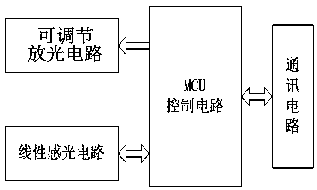

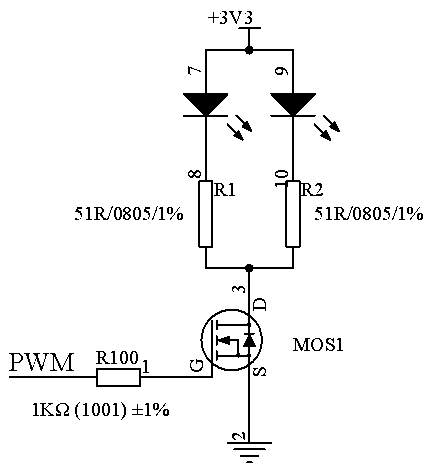

[0027] A cloth boundary recognition sensor of a sewing machine includes a lens group 4 and a linear CCD photosensitive chip 1 located on one side of the lens group 4, and is characterized in that at least two groups are arranged around the lens group 4 and directed to the other side of the lens group. The linear light source composed of 2 and the concave lens 3 is provided with a reflector 7 that reflects the linear light source back to the lens group 4 on the other side of the lens group.

[0028] A cloth boundary recognition device for a sewing machine, which is characterized by comprising a lens group 4 and a linear CCD photosensitive chip 1 on one side of the lens group 4. At least two groups are arranged around the lens group 4 and directed to the other side of the lens group. The linear light source composed of 2 and concave lens 3 is provided on the other side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com