Gel plugging slurry for drilling, preparation method of plugging slurry and slug plugging method

A technology of plugging slurry and gel, which is applied in drilling compositions, chemical instruments and methods, and earth-moving drilling, etc. low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

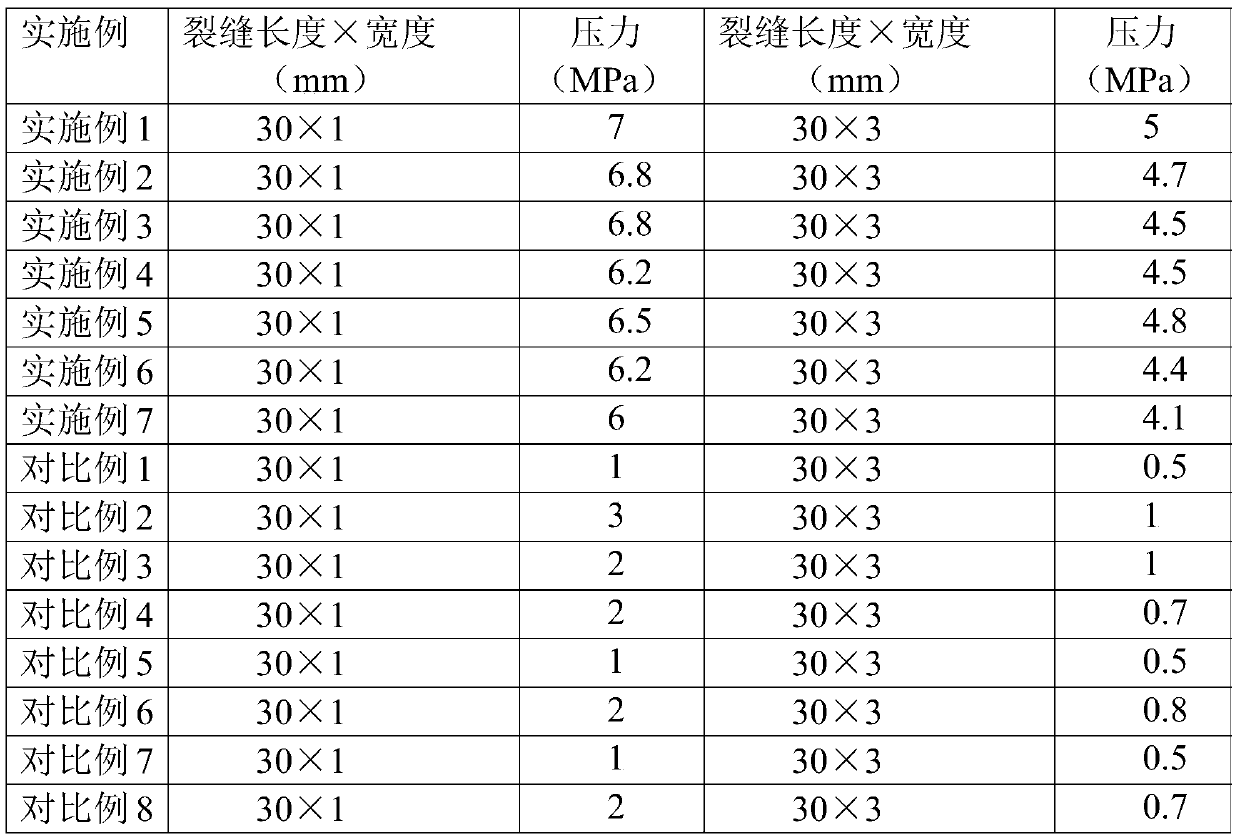

Examples

preparation example Construction

[0041] A kind of preparation method of gel plugging slurry for drilling according to a preferred embodiment of the present invention, wherein, the method comprises the following steps:

[0042] (1) Pour water into the mixer and stir evenly at 2000-4000 rpm, add special gel and stir evenly for 10-20 minutes;

[0043] (2) Slowly add the bridging material along the stirring rod and stir evenly for 25-35 minutes;

[0044] (3) Slowly add the connecting material along the stirring rod and stir evenly for 25-30 minutes;

[0045] (4) Finally, slowly add the filling material along the stirring bar and stir evenly for 10-15 minutes.

[0046] Among them, in the present invention, the advantage of adding slowly along the stirring rod is that it can make the solid phase components more uniformly dispersed in the lost circulation slurry.

[0047] Wherein, in the present invention, the slow adding speed may be 0.5-2 g / s, preferably 1-1.5 g / s.

[0048] The third aspect of the present inven...

Embodiment 1

[0061] This example is to illustrate the gel plugging slurry prepared by the preparation method of the present invention

[0062] Add 6g of special gel ZND-2 to 100 ml of tap water (this special gel is a light yellow transparent particle, the particle size is between 8mm, at a shear rate of 1200s -1 Under conditions, the viscosity is 30mPa.s), and after stirring for 15 minutes under the environment of 3000 rev / min at the stirring rate, slowly add 5g glass fiber and 10g asbestos fiber along the stirring rod, and under the environment of 3000 rev / min at the stirring rate After stirring for 30 minutes, slowly add 30g of walnut shells (the particle size of the walnut shells is 5mm) along the stirring rod, and then slowly add 35g of nanobarite powder along the stirring rod after stirring for 27 minutes at a stirring rate of 3000 rpm (The particle size of the nanobarite powder is 5 μm). After stirring for 12 minutes, the plugging slurry A1 was obtained.

[0063] A plugging instrume...

Embodiment 2

[0065] This example is to illustrate the gel plugging slurry prepared by the preparation method of the present invention

[0066] According to the same method as in Example 1 to prepare the plugging slurry, the difference is: 3g of special gel ZND-2 is added to 100 milliliters of tap water (this special gel is light yellow transparent particles, and the particle size is between 5mm between, at a shear rate of 1000s -1 Under conditions, the viscosity is 20mPa s), and after stirring for 10 minutes under the environment of 2000 rev / min at the stirring rate, slowly add 2g glass fiber and 12g asbestos fiber along the stirring rod, and under the environment of 2000 rev / min at the stirring rate Stir for 25 minutes, then slowly add 25g of walnut shells along the stirring rod, stir for 25 minutes at a stirring rate of 2000 rpm, then slowly add 30g of nanobarite powder along the stirring rod, and stir for 10 minutes to obtain plugging Pulp A2.

[0067] A plugging instrument was used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com