Method for preparing high-activity light calcined magnesia with fixed bed-fluidized bed at multiple flow states

A light-burned magnesium oxide and fluidized bed technology, applied in the field of metallurgy, can solve problems such as high energy consumption, insufficient heat transfer and reaction time, and high labor intensity, and achieve the goal of avoiding environmental pollution, avoiding flying losses, and improving the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

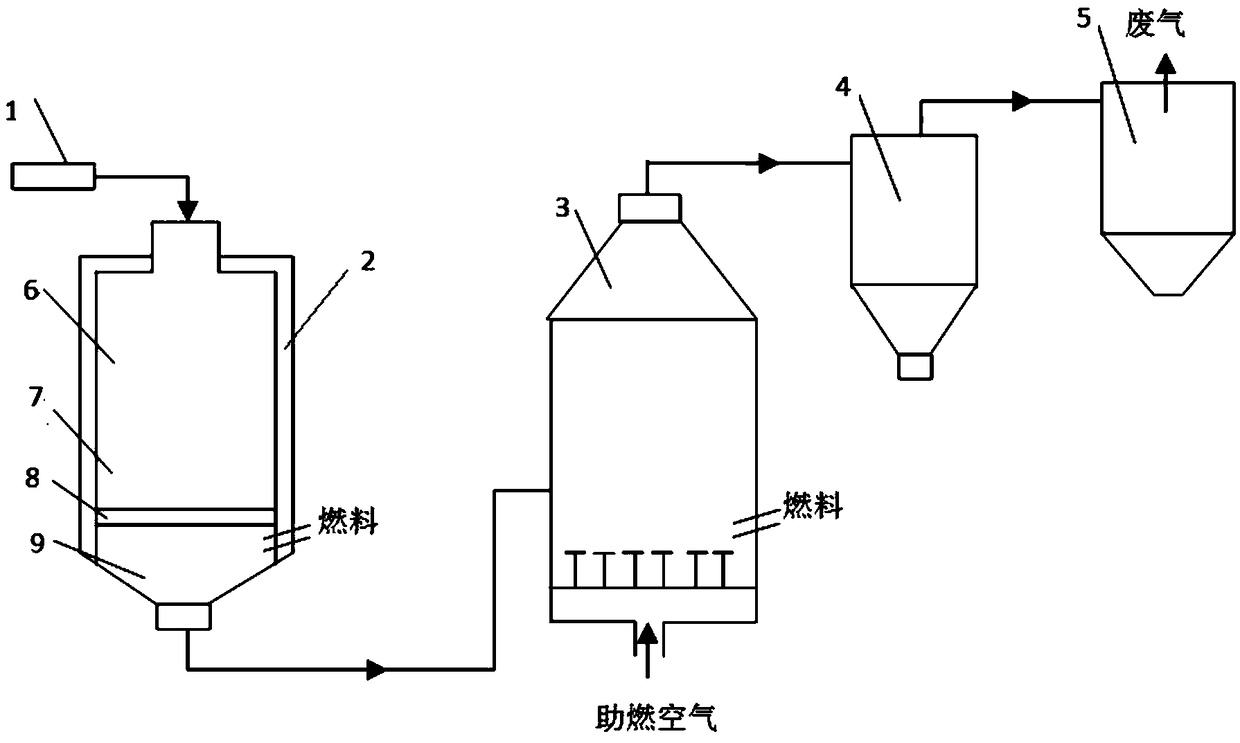

[0022] The method for preparing high-activity light-burned magnesium oxide in a fixed bed-fluidized bed multi-fluid state, the specific steps are as follows:

[0023] (1) The magnesite raw material with a particle size of 30-300mm is sent to the fixed bed calcining and decomposition furnace through the electric feeding car 1 of the feeding system. The material enters the preheating zone through the top of the furnace, and in the preheating zone, the magnesite is preheated to 200-700°C by means of the heat of the flue gas going up from the calcination zone, and the material preheated by the preheating zone goes down to the calcination zone, and is burned The chamber is located under the furnace bar, and the fuel is sent into the combustion chamber by the burner. The flame and heat formed by the fuel combustion pass through the furnace bar to roast the magnesite. The roasting temperature is 700-1000°C. The massive magnesite decomposes to form smaller blocks and powders, and at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com