A device and method for treating organic matter with high moisture content

A technology with high water content and organic matter, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, sludge treatment, etc., can solve problems such as high water content, difficult dehydration, and low product quality. Achieve the effects of improving quality, increasing dehydration rate, and improving anaerobic digestion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

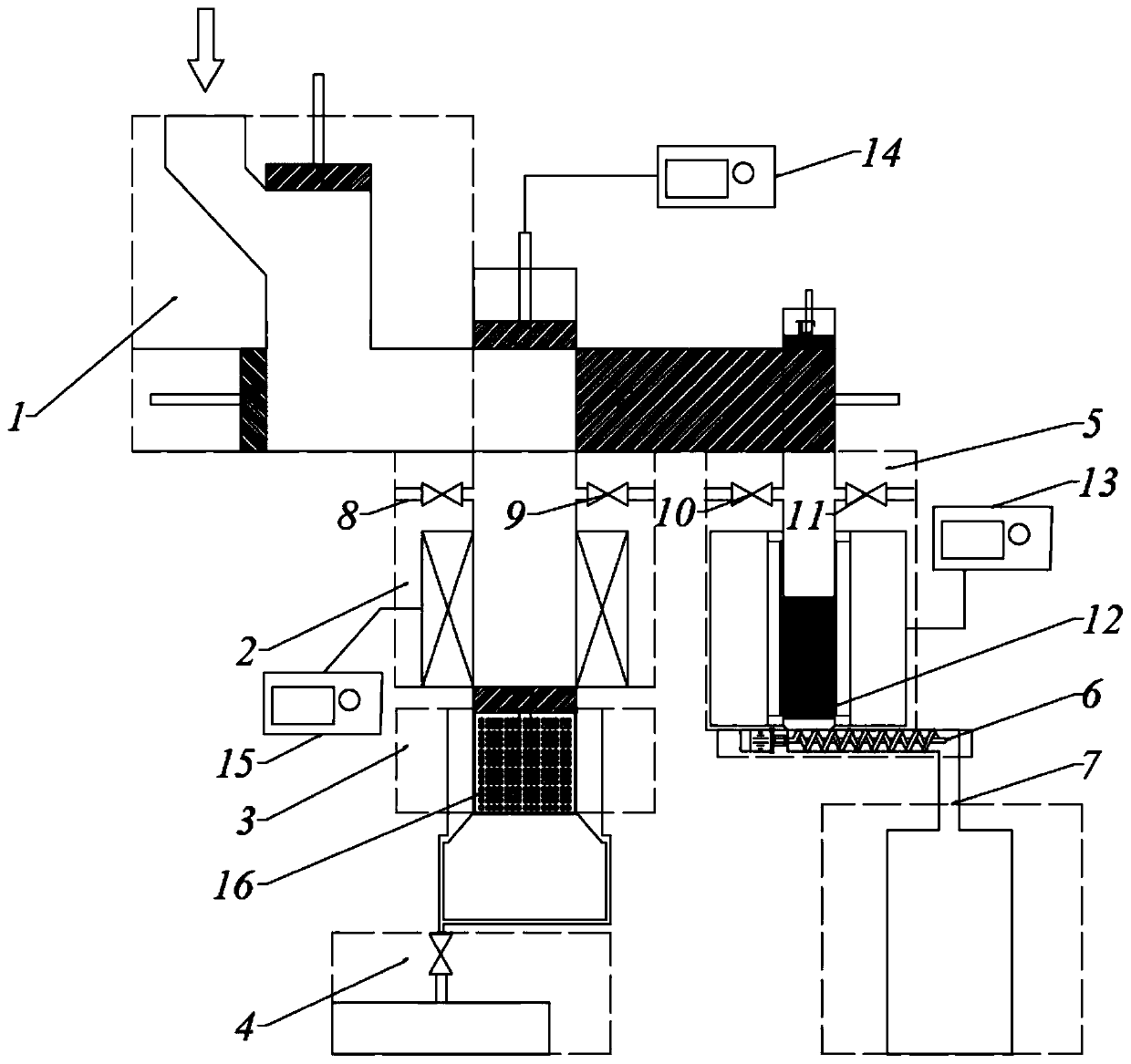

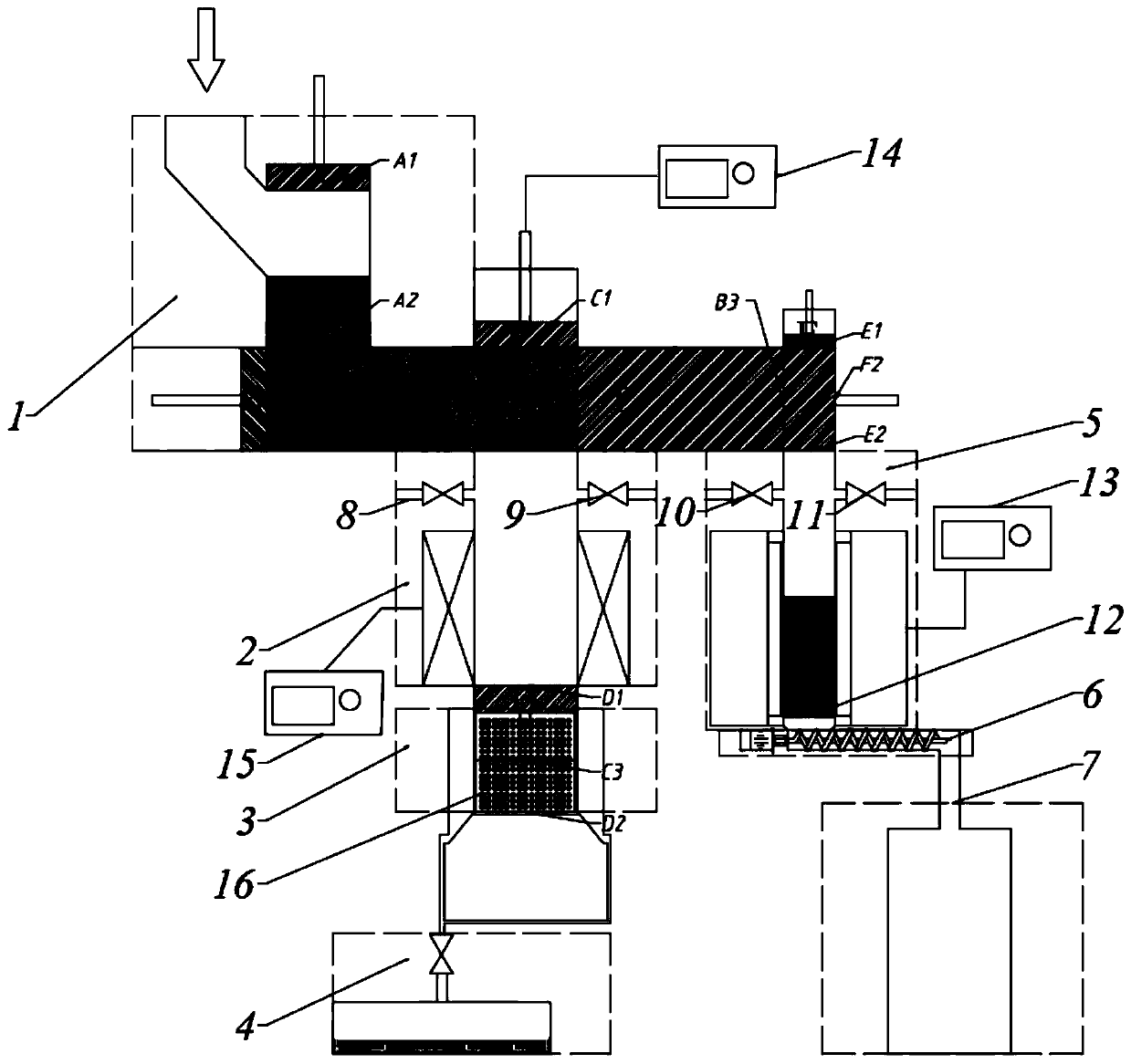

[0030] The specific technical methods and devices of the present invention will be described in detail and completely below in conjunction with the accompanying drawings and specific embodiments. The described specific implementation methods are only some specific embodiments of the present invention, but the design concept of the present invention is not limited to Therefore, any non-substantial modification of the present invention by using this concept shall be regarded as an act infringing the protection scope of the present invention.

[0031] refer to figure 1 , a device for treating organic matter with high moisture content of the present invention, comprising: a feeding unit 1, a hydrothermal drying unit 2, a filter press unit 3, a liquid storage unit 4, a thermal conversion unit 5, and a continuous discharge unit 6 and solid storage unit 7.

[0032] The feeding port of the feeding unit 1 is used to feed the organic matter with high water content to be treated, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com