Stacking, loading and carrying device for hollow bricks and method thereof

A handling device and technology of hollow bricks, which are applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of unstable clamping, low efficiency and pinch damage of hollow bricks, so as to avoid the scattered bricks and prevent The effect of scattered bricks to avoid destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

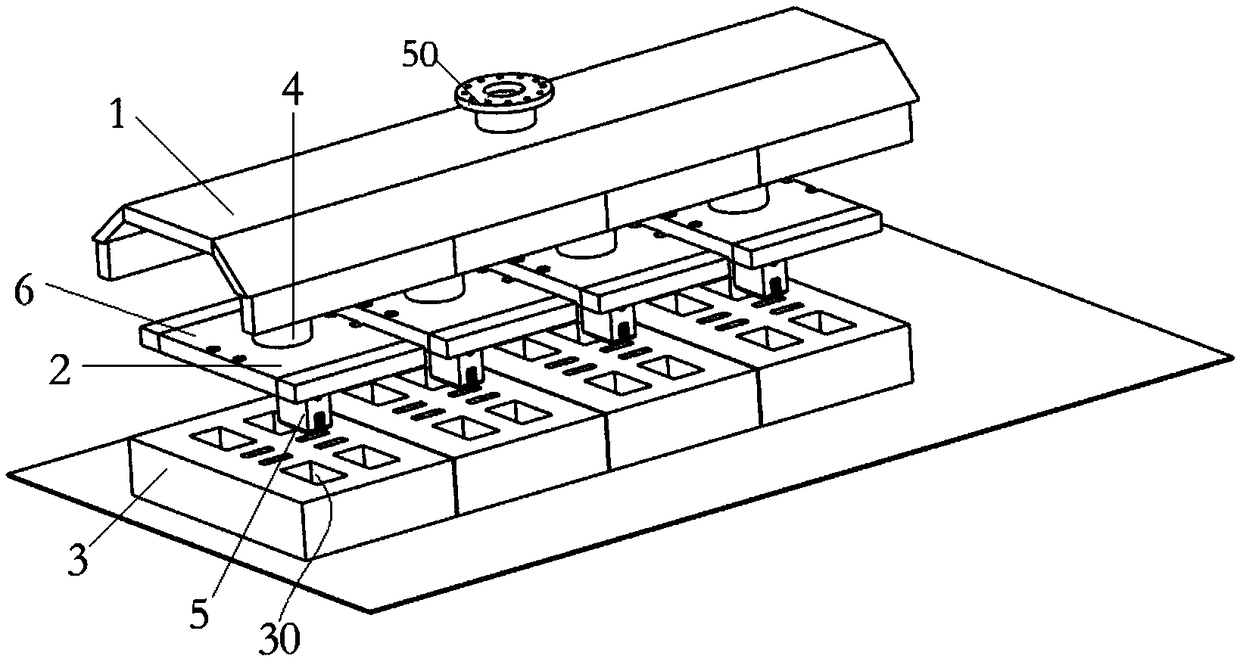

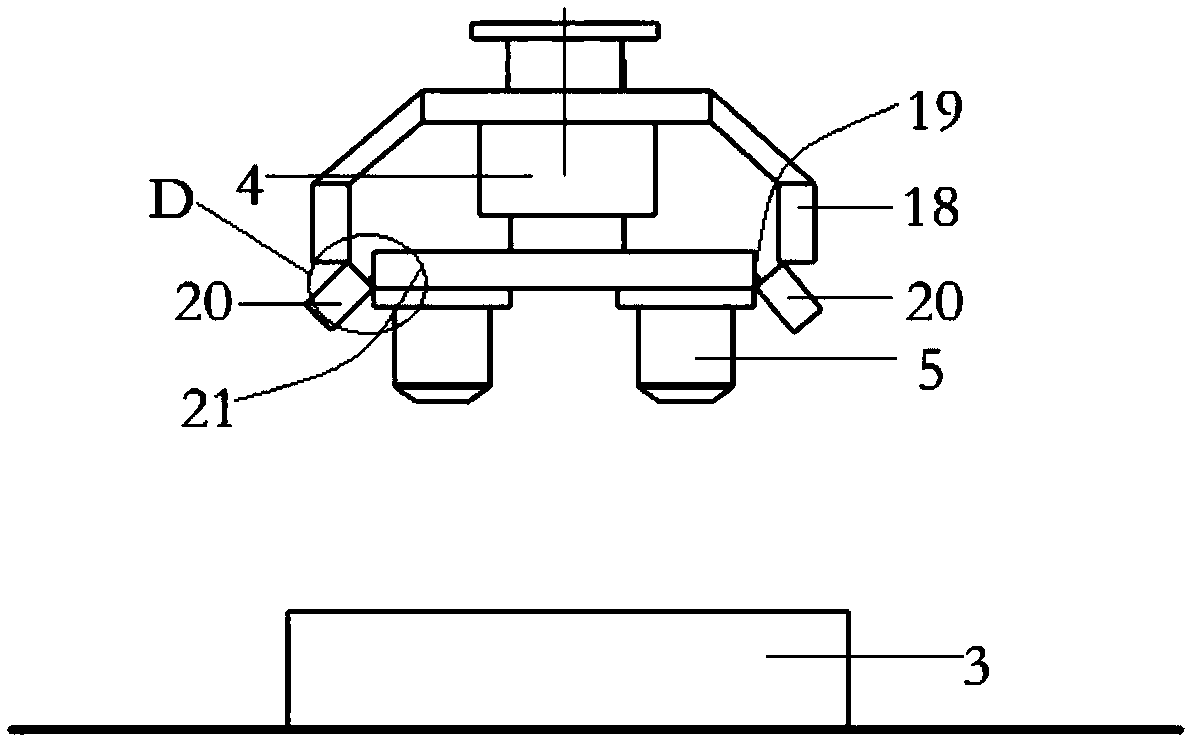

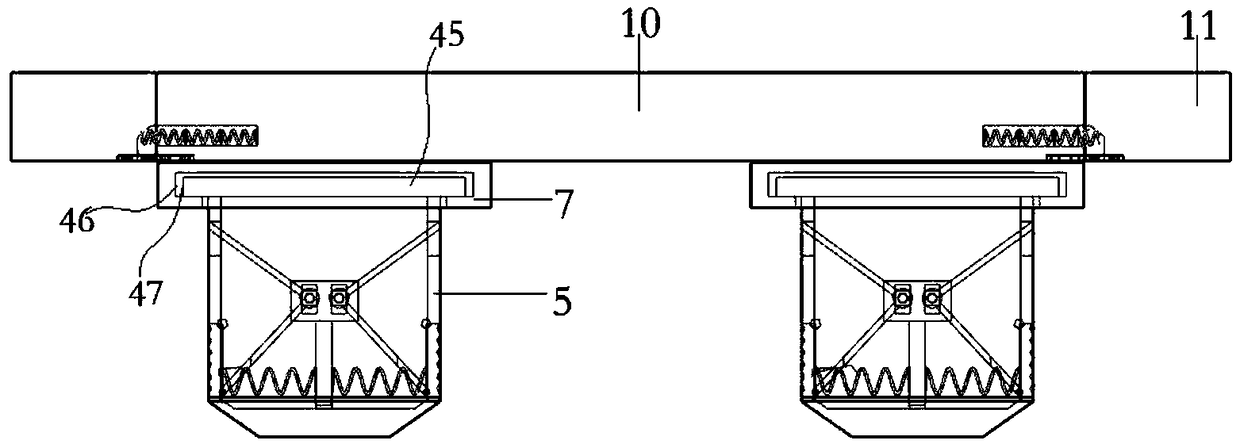

[0036] as attached figure 1 And attached figure 2As shown, a hollow brick stacking loading and handling device includes a support frame 1, a clamping device 2 and a lifting device 4. The support frame 1 is arranged at the driven end of the mechanical arm, and the top of the support frame 1 is provided with a connection The flange 50 is connected with the mechanical arm, and several lifting devices 4 are arranged in linear intervals below the support frame 1. The lifting devices are telescopic cylinders, and the driven ends of several lifting devices 4 are respectively provided with clamping devices. 2. The clamping device 2 is displaced up and down relative to the support frame 1 through the lifting device 4; the clamping device 2 includes a top plate 6 arranged at the driven end of the lifting device 4 and a number of bottom plates arranged on the bottom side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com