Horizontal circulation type magnetic levitation conveyor belt

A conveyor belt and circular technology, which is applied in the field of horizontal circular magnetic levitation conveyor belt, can solve the problems of easy wear of the moving guide rail and supporting guide rail, inability to automatically unload goods, and large loss of power components, so as to avoid derailment, enrich unloading, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

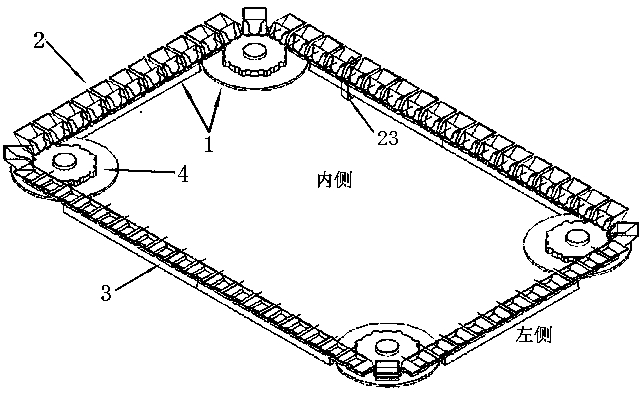

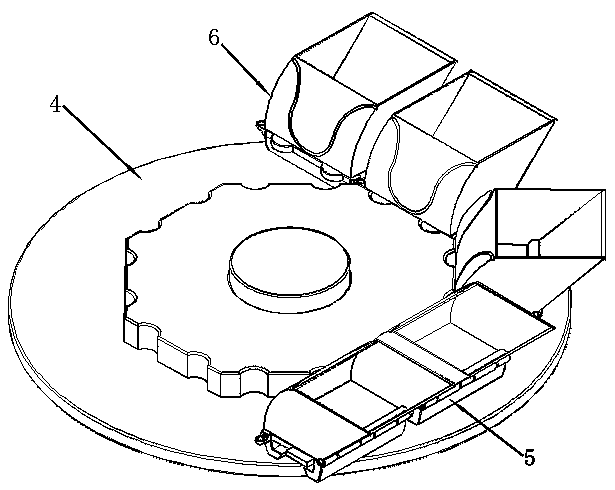

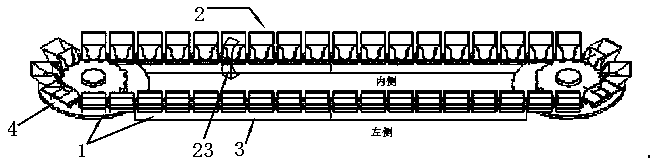

[0033] A horizontal circulating suspension conveyor belt, including a track 1 and a conveyor belt 2, the track 1 is composed of a horizontally placed straight section guide rail 3 and a turning guide wheel 4, the turning guide wheel 4 connects each straight section guide rail 3 end to end, and the conveyor belt 2 is set on the track 1, the conveyor belt 2 is composed of several moving units, the moving unit includes a moving seat 5 and a box body 6, wherein, the bottom of the moving seat 5 is equipped with a secondary power element, and the rear side of the moving seat 5 is provided with a first hollow shaft 7, and the box The bottom of the rear side of the body 6 is provided with a second hollow shaft 8, through the cooperation of the first hollow shaft 7 and the second hollow shaft 8, the box body 6 is hinged on the kinematic seat 5, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com