Automatic light guide plate hot-press transfer and lamination integrated equipment

A technology of heat transfer printing and light guide plate, which is applied in transfer printing, rotary printing machine, flat plate printing machine, etc. It can solve the problems that the light guide plate cannot meet high precision, the processing process is discontinuous, and it is prone to offset. , to achieve the effects of less error prone, good cleaning effect and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

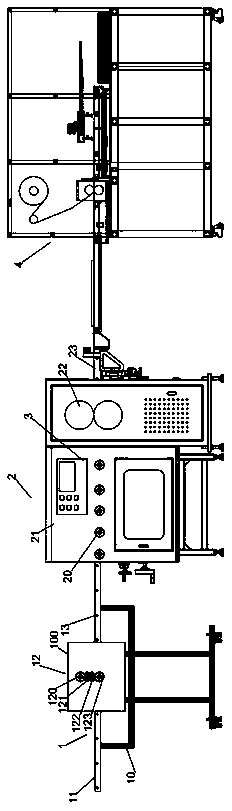

[0038] Such as figure 1 As shown, the present invention includes a feeding device 1 , a hot press 2 , a laminating machine 4 , and a PLC control terminal 3 in sequence. The PLC control terminal 3 is electrically connected with the feeding device 1, the hot press 2 and the laminating machine 4, and is used to control the working procedures of the entire equipment.

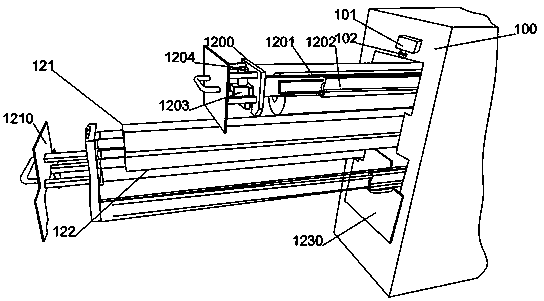

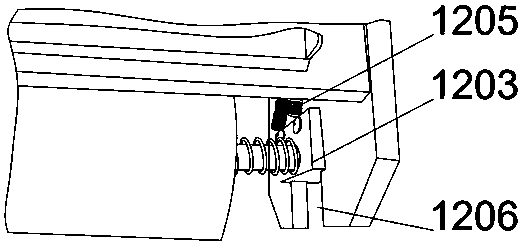

[0039] The feeding device 1 includes a feeding frame 10 and a first feeding conveying device 11 , a second feeding conveying device 13 and a cleaning roller set 12 installed on the feeding frame 10 . The first feeding conveying device 11 and the second feeding conveying device 13 are respectively arranged on two sides of the cleaning roller set 12 . The main function of the feeding device 1 is to clean the light guide plate to be processed, remove the uneven dust and impurities on the surface of the light g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com