Tool used for fast and accurately installing and disassembling valve sleeve

A precise installation and fast technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of inability to disassemble, time-consuming installation and disassembly, jamming, etc., to achieve easy assembly, simple structure, fast and accurate installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

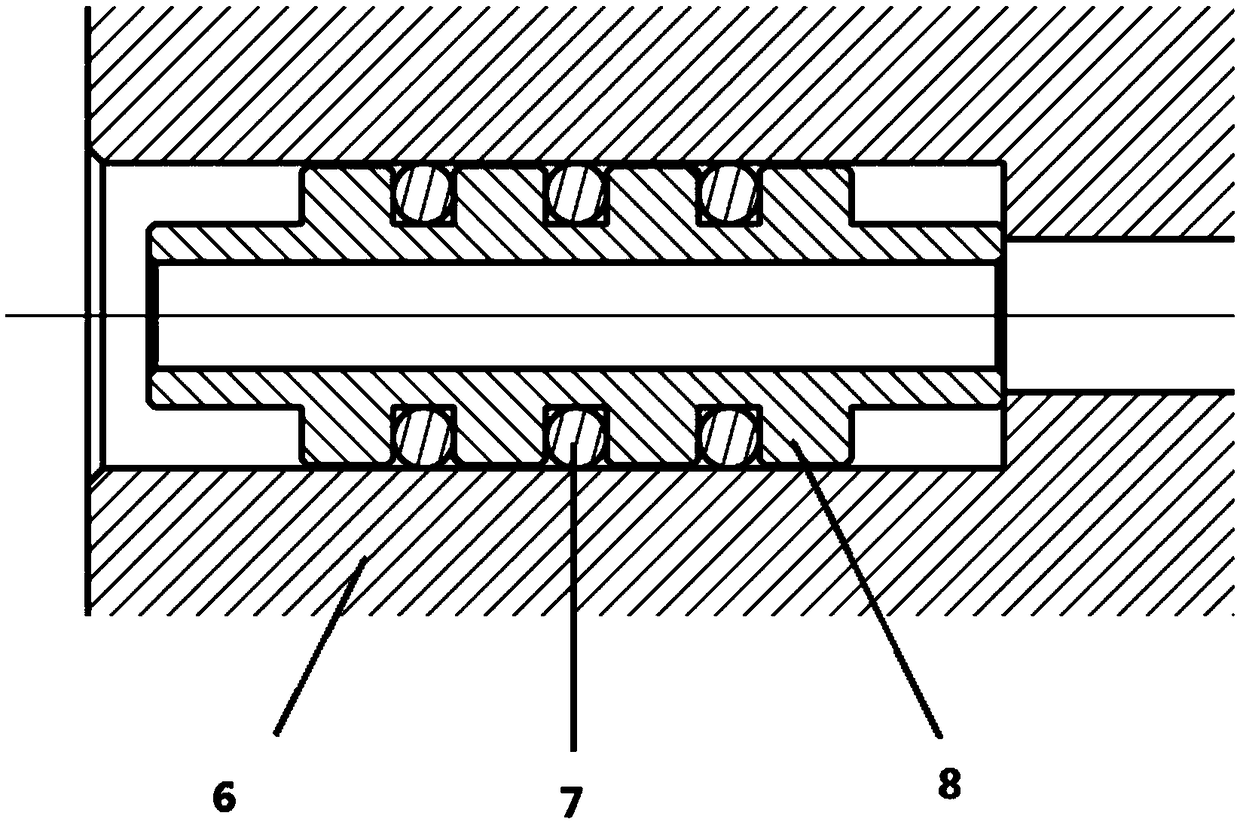

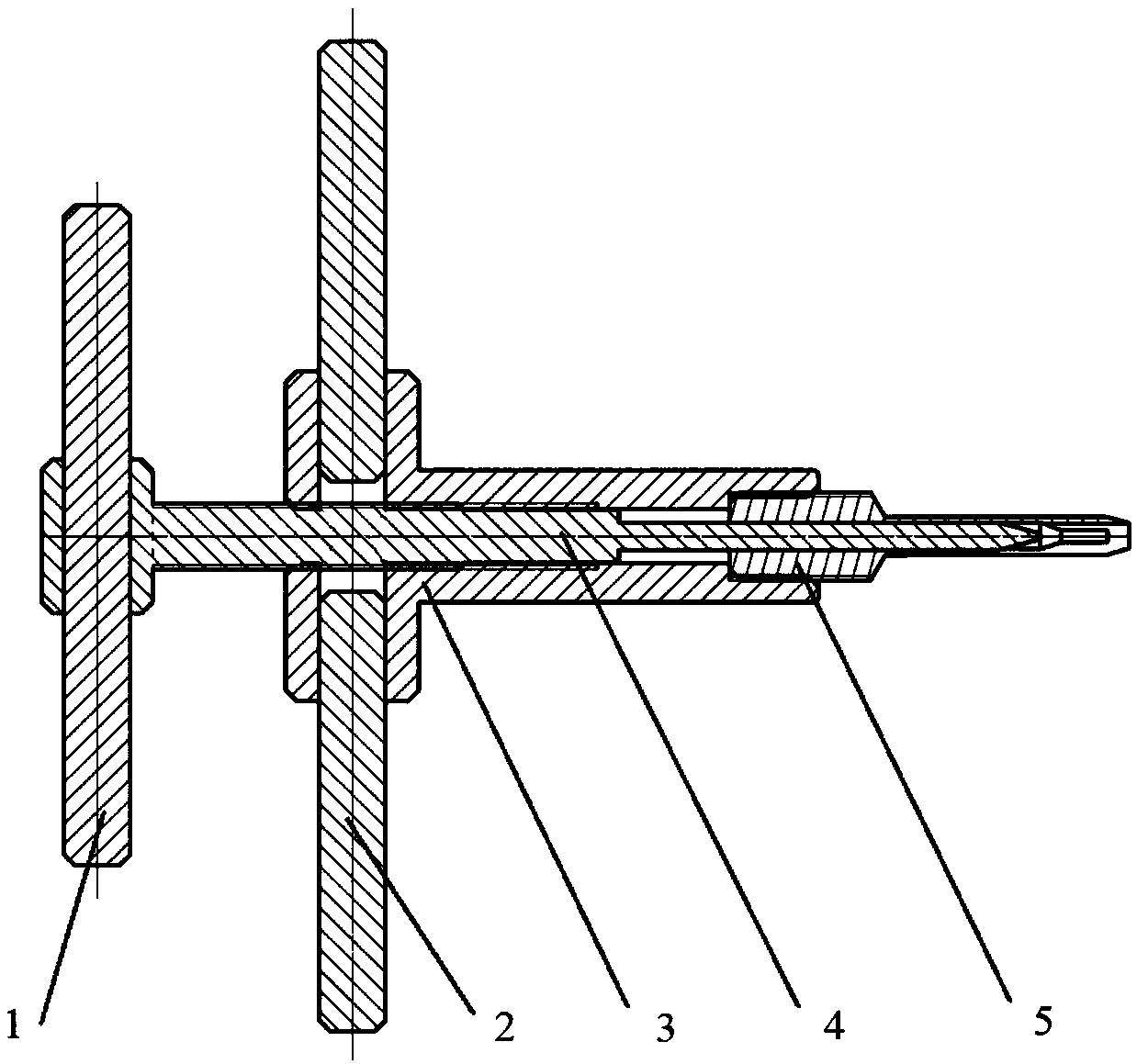

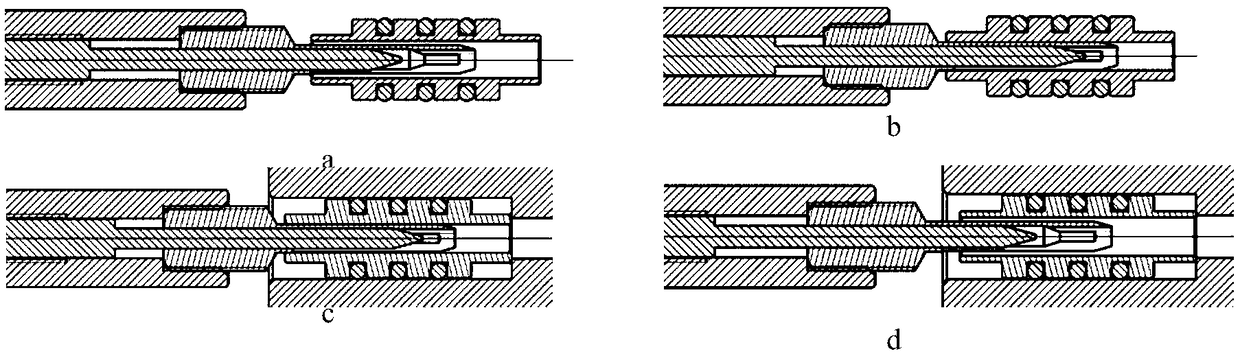

[0014] See attached figure 2 , a tool for fast and precise installation and disassembly of valve sleeves, consisting of a first pin 1, a second pin 2, a housing 3, a mandrel 4, and an elastic collet 5; the first pin 1 is fixedly connected to the mandrel 4 Form the first handle, turn the first handle, and the mandrel rotates thereupon; the second pin 2 is fixedly connected with the housing 3 to form the second handle, hold the second handle tightly, and the whole device can be picked up or put down; the collet 5 is threaded and The shell 3 is connected as a whole, and the front end of the collet 5 is set in the form of a gap; the mandrel 4 is threadedly matched with the shell 3 and passes through the center hole of the collet 5. When the mandrel 4 rotates, due to the effect of the thread , the mandrel 4 will move back and forth in the shell and the collet. When the mandrel moves forward, the collet will expand under the action of the mandrel; conversely, when the mandrel moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com