Grinding wheel forming die demoulding device

A grinding wheel forming die and demolding device technology, applied in grinding devices, manufacturing tools, metal processing equipment, etc., can solve the problems of stable product quality, poor consistency, high labor intensity, and reduced grinding wheel enhancement effect, and achieve improved grinding wheels. The effect of forming quality, avoiding skid offset, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

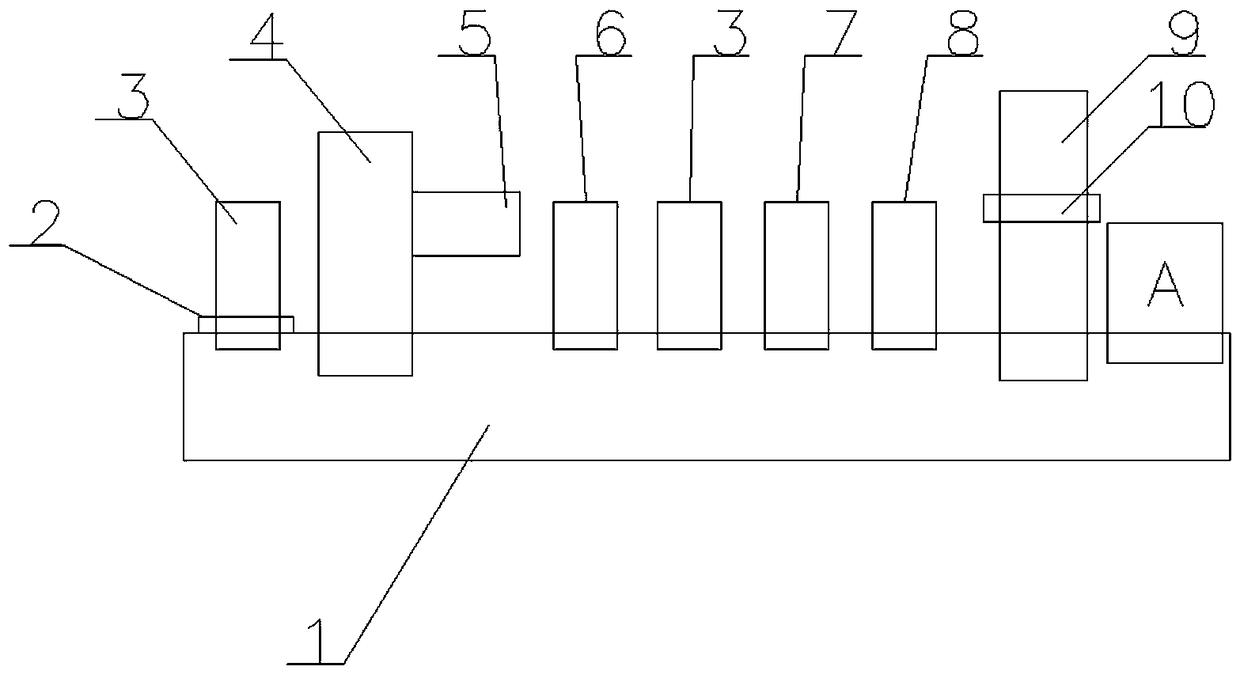

[0046] figure 1 As shown, an automatic high-precision grinding wheel production line includes a production track 1, a grinding wheel forming mold 2, a mesh placement system 3, a feeding system 4, a feeding system 5, a scraping system 6, a pressing system 7, and a core ring placement system 8 , molding machine 9, film pulling system 10. The grinding wheel forming mold 2 is slidingly set on the production track 1, and the production track 1 is sequentially equipped with a mesh placement system 3, a feeding system 4, a feeding system 5, a scraping system 6, a mesh placement system, a pressing system 7, a core Ring placement system 8 and molding machine 9, the molding machine 9 is provided with a film drawing system 10 corresponding to the grinding wheel forming mold 2 on the production track 1, and the molding machine 9 is followed by a demoulding device A.

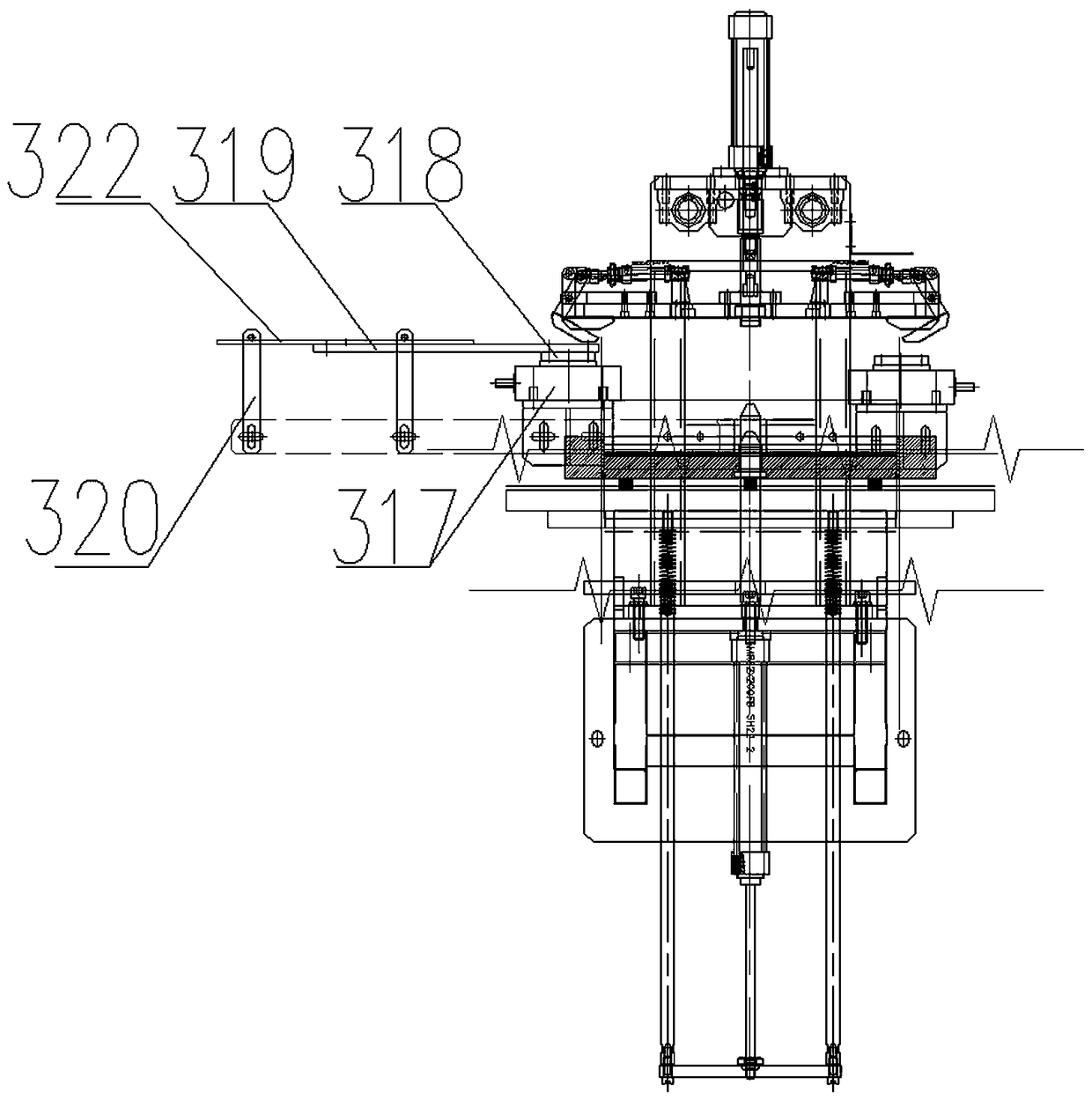

[0047] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com