Material part quick demolding structure of anchor chain transverse stop punch

A technology of punching and demoulding, which is applied in the field of anchor chains, can solve the problems of unsatisfactory and reliable removal of parts 50, waste of return time, scratching and other problems, and achieve easy cooperation with automated operations, easy installation, and simplified components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

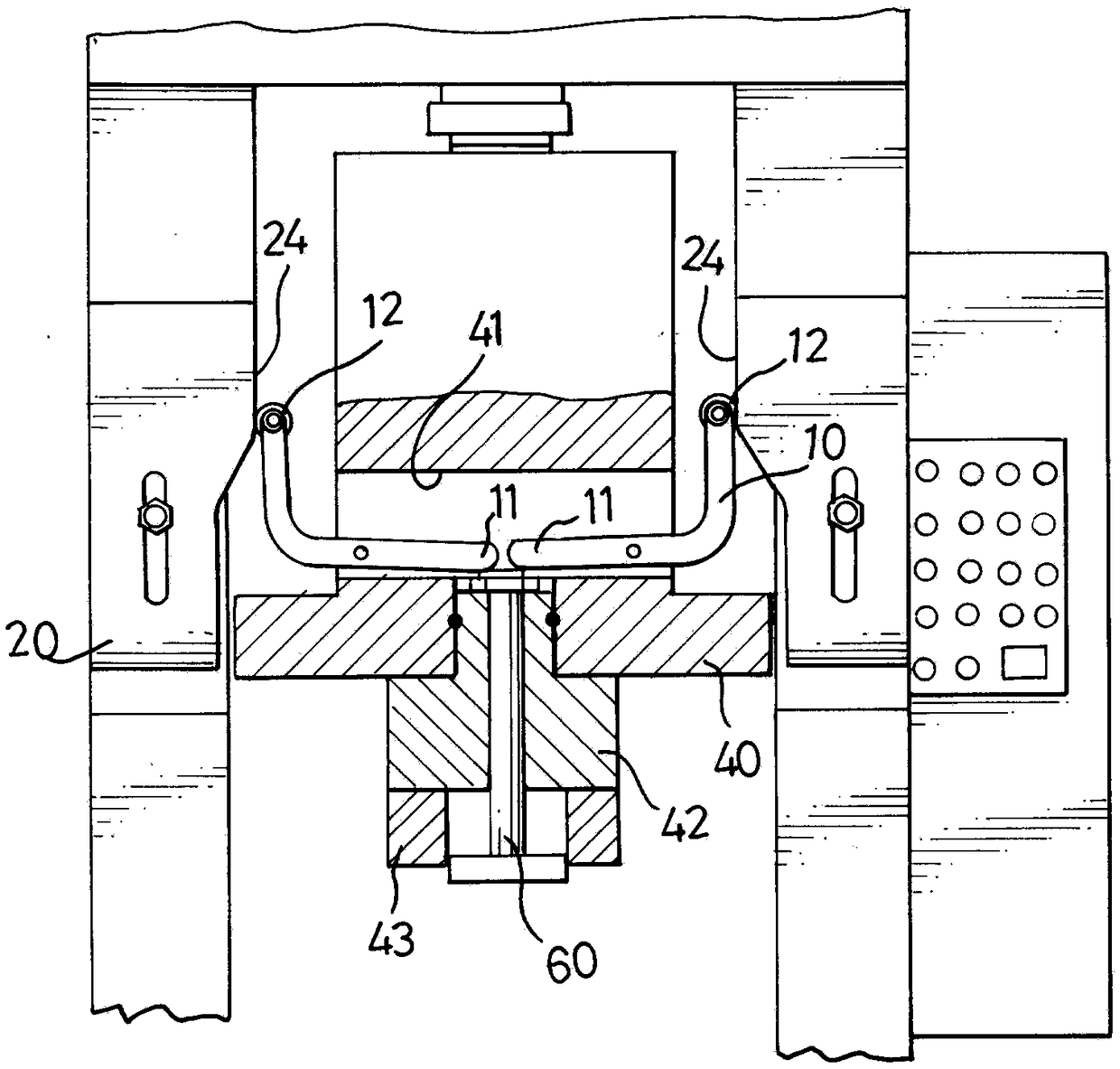

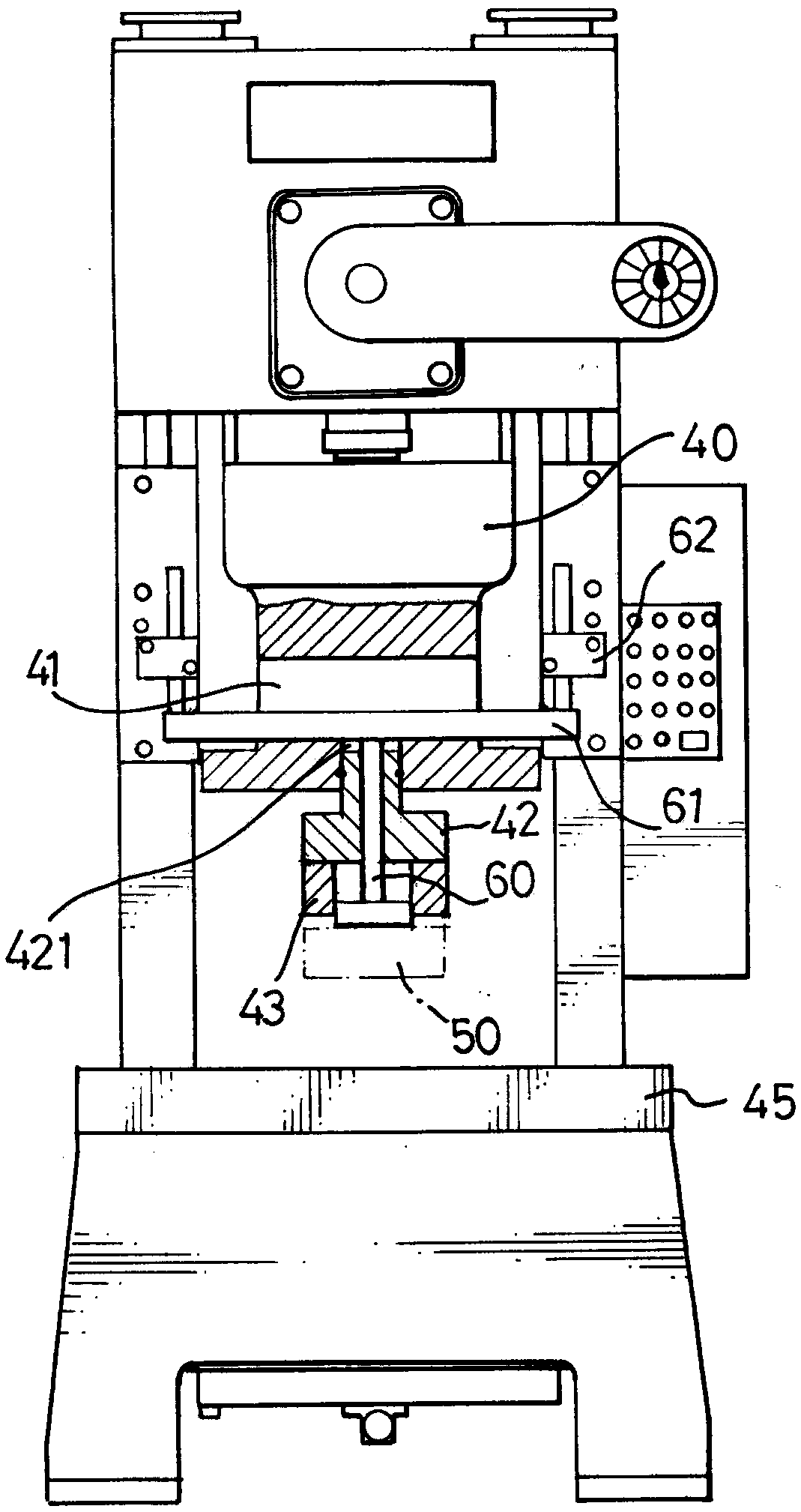

[0017] like figure 1 and 2 As shown, a fast demoulding structure of the material of the anchor chain crosspiece punch press has little change to the punch itself, so the positions of the die head 42, the upper die 43, and the hammer 40 will not change, and the main change makes the material 50 The demoulding efficiency is more effective and faster.

[0018] It includes a pair of stripping arms 10 pivotally arranged in the long hole area 41 of the die head 42, and orientation blocks 20 fixed on both sides of the punch body. The stripping arm 10 is a nearly L-shaped support arm bar, the vertical end is slightly tilted towards the outside, and the end of the vertical end is recessed to pivotally install a guide wheel 12 therebetween. The guide wheel 12 can be a wheel or a bearing. The horizontal end is the impact end 11; the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com