Novel pinch roll

A pinch roller and a new type of technology, applied in the field of new pinch rollers, can solve the problems of easy cracking or peeling, limited depth of the working layer, insufficient strength, etc., and achieve a small amount of grinding machine repair, good surface quality, and reduce product rejection rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

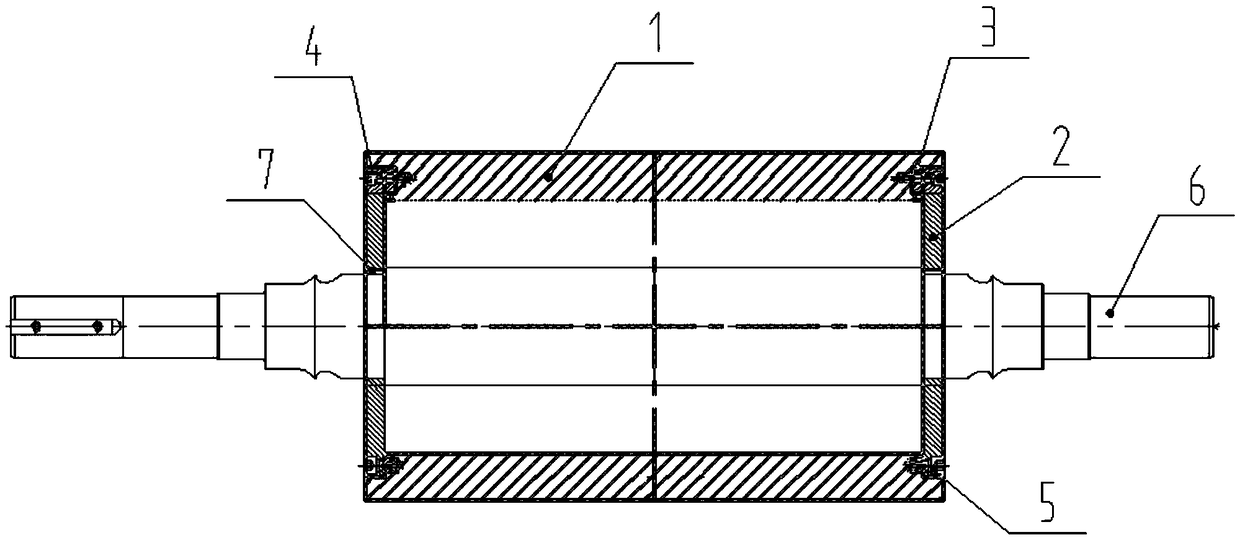

[0021] combined with figure 1 , figure 2 .

[0022] When the present invention is actually implemented, a new type of pinch roller includes an upper pinch roller and a lower pinch roller. The main body length of the upper pinch roller mandrel 6 is greater than the main body length of the upper pinch roller sleeve 1, and the two ends of the opening of the upper pinch roller sleeve 1 are respectively provided with end face baffles 2, and the end face baffles One side of the plate 2 is provided with a connection key block 3, and the connection key block 3 is provided with a key block fastening bolt 4 for fixing, and the end face baffle 2 is provided with a connection key block 3 on the opposite side for fixing. The baffle fastening bolt 5, the middle part of the upper pinch roller mandrel 6 is provided with a shaft shoulder that matches the inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com