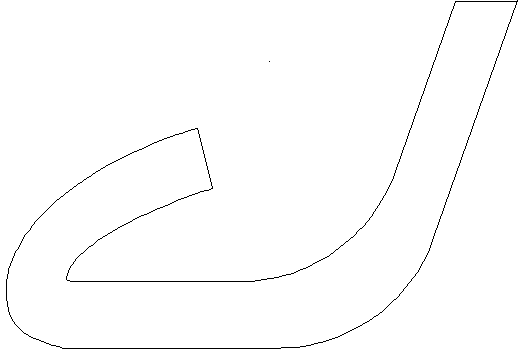

Locking mouth structure of hot-rolling U-shaped steel sheet pile

A technology of steel sheet piles and interlocks, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of lax fastening, high residual stress, large deformation stress of cold-formed steel sheet piles, etc., and save steel consumption , large section modulus and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

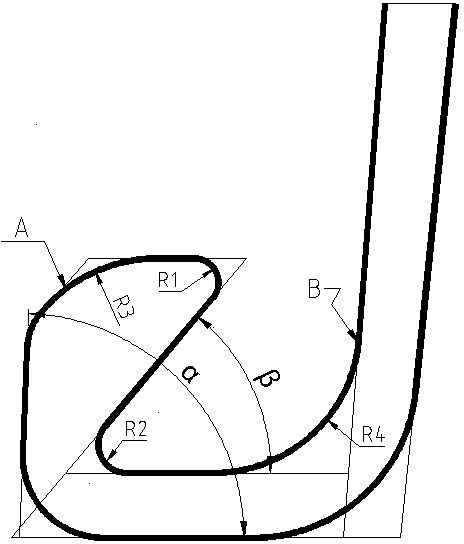

[0027] Example 1: According to the outer inclination angle of the lock port α=88°, the bevel angle of the contact surface of the lock port β=50°, and the radius R of the outer circle of the lock port end 1 =3mm, inner circle radius R 2 =3.5mm, radius R of the outer circle of the side end of the lock 3 =20mm, corresponding to the radius R of the inner circle at the root of the lock 4 =19mm and other main control data, using a large section steel rolling mill, hot rolling can produce qualified products.

Embodiment 2

[0028] Embodiment 2: According to the outer inclination angle of the lock mouth α=85°, the bevel angle of the lock mouth contact surface β=55°, and the radius R of the outer circle of the lock mouth end 1 =3.5mm, inner circle radius R 2 =4mm, radius R of the outer circle of the side end of the lock 3 =18mm, corresponding to the radius R of the inner circle at the root of the lock 4 =18mm and other main control data, using a large section steel rolling mill, hot rolling can produce qualified products.

Embodiment 3

[0029] Embodiment 3: According to the outer inclination angle of the lock port α=80°, the bevel angle of the contact surface of the lock port β=38°, and the radius R of the outer circle of the lock port end 1 =4mm, inner circle radius R 2 =4.5mm, radius R of the outer circle of the side end of the lock 3 =17mm, corresponding to the radius R of the inner circle at the root of the lock 4 =17mm and other main control data, using a large section steel rolling mill, hot rolling can produce qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com