Combined double-shaft shredding machine and working method thereof

A dual-shaft shredder and combined technology, applied in grain processing, etc., can solve problems such as unsatisfactory customers, achieve the effects of reduced wear, uniform force, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 1 to Figure 5As shown, the combined twin-shaft shredder of this embodiment includes a crushing roller 1, a cabinet 2, a shredding cutter 4, a first power system 5 and a second power system 6, and the first power system 5 and the second power system System 6 is respectively installed on the cabinet 2, and the first power system 5 includes the first motor 51 and the first speed reducer 52 connected with the first motor 51, and the first speed reducer 52 is connected with crushing roller 1; The second power system 6 It includes a second motor 61 and a second reducer 62 connected to the second motor 61. The second reducer 62 is connected to the shredding tool 4. An inclined rolling platform 21 is provided on the feeding upper part of the cabinet 2, and the crushing roller 1 passes through the The bearing 3 is fixed on both sides of the rolling platform 21, and the effective distance between the crushing roller 1 and the rolling platform 21 is 10-15 mm; Abov...

Embodiment 2

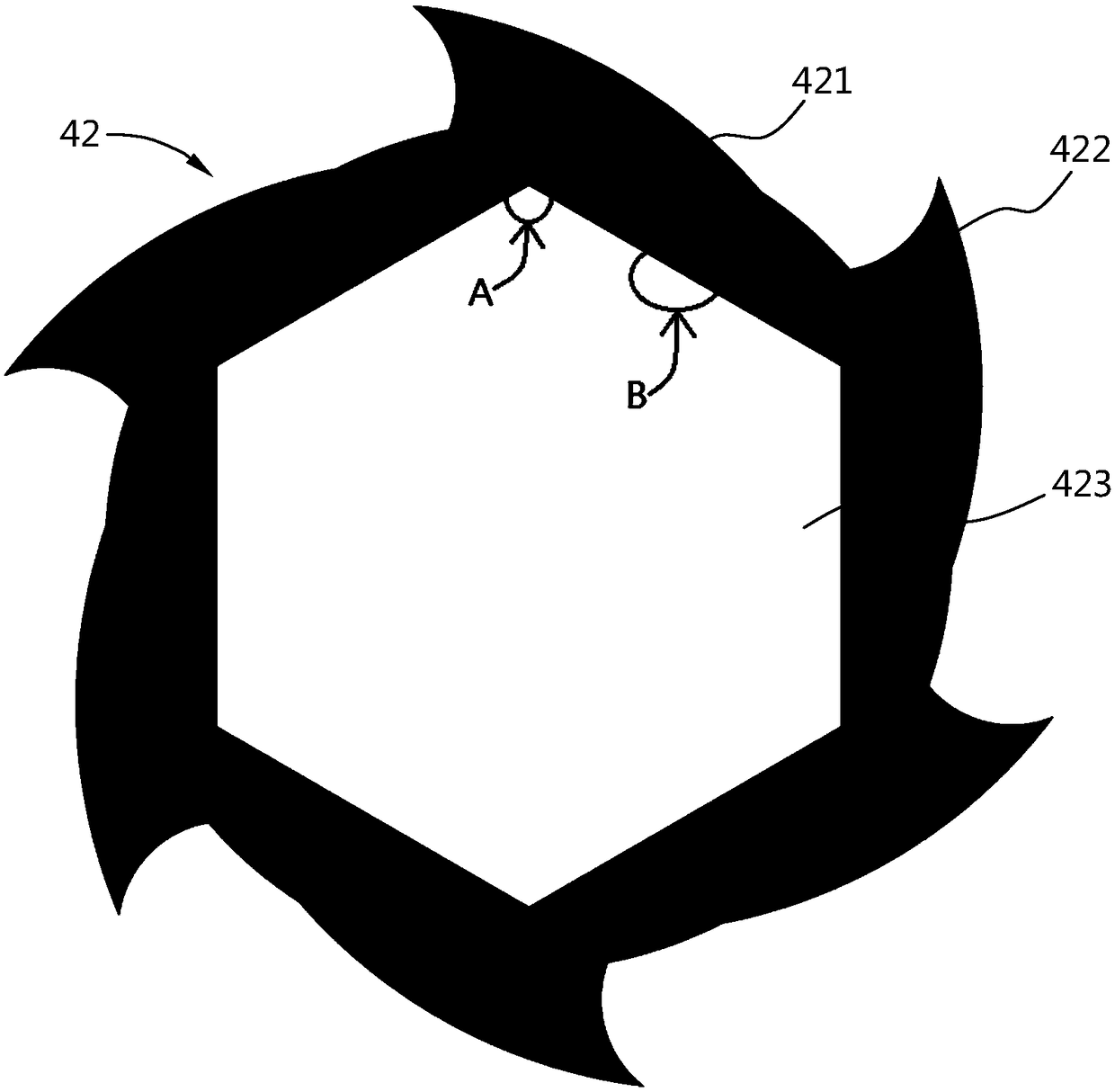

[0042] The structure of this embodiment is basically the same as that of Embodiment 1, except that the shredding tool 4 includes a cutter shaft 41 and an integrally formed blade 42 matched with the cutter shaft 41, the integrally formed blade 42 includes a blade body 421, and the blade body 421 is provided with a blade 422, and the center of the blade body 421 is provided with a connection hole 423, the shape of the connection hole 423 is a regular n-gon, wherein 12≥n≥5, and the corners of the regular n-gon are connected by arc protrusions. The blade body 421 is evenly provided with n blades 422, and the blade 422 includes a blade tip, a first connection surface and a second connection surface, wherein the first connection surface and the second connection surface are arc surfaces, and the first connection surface The radian is consistent with the radian of the second connection surface. In this embodiment, specifically n=6, the shape of the connecting hole 423 is a regular he...

Embodiment 3

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in combination Figure 4 with Figure 5 , the radius r1 of the arc convex is consistent with the radius r2 of the arc surface, where r1=r2=(n / 36)mm. Specifically, 12≥n≥5, then n=5, 6, 7, 8, 9, 10, 11, 12, put the above values into the above formula, and get r1=r2=0.139mm, 0.167mm, 0194mm, 0.222 mm, 0.25mm, 0.278mm, 0.305mm, 0.333mm.

[0046] Considering that the food waste contains grease, the grease will corrode the surface of the crushing roller 1, therefore, the surface of the crushing roller 1 is coated with a protective film, the thickness of which is 0.5-1 mm, and the specific thickness is selected according to Need, generally choose 0.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com