A new gas-liquid film contactor

A gas-liquid membrane contactor and gas-liquid contact technology, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of large pressure drop on the air side, inability to achieve compactness, and large system volume, and achieve The effect of preventing water vapor condensation, enhancing heat and mass transfer on the air side, and enhancing heat and mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

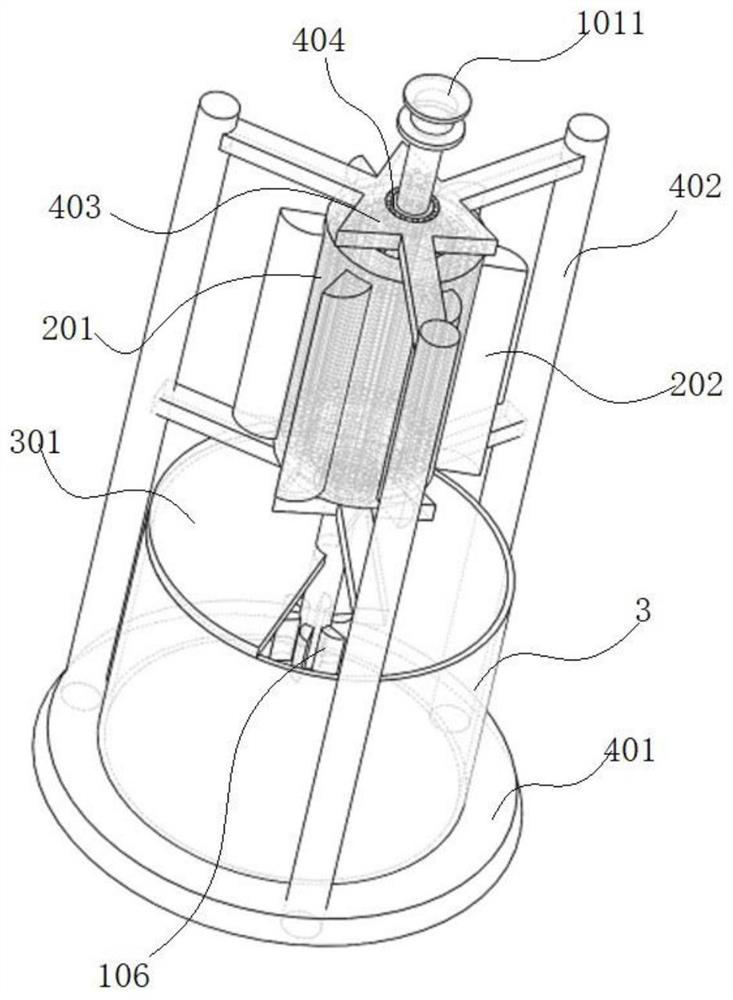

[0051] A new type of gas-liquid membrane contactor, including a gas-liquid delivery unit, a gas-liquid contact unit, a liquid storage unit 3 and a heating device, the gas-liquid contact unit and the liquid storage unit are matched through the gas-liquid delivery unit 3;

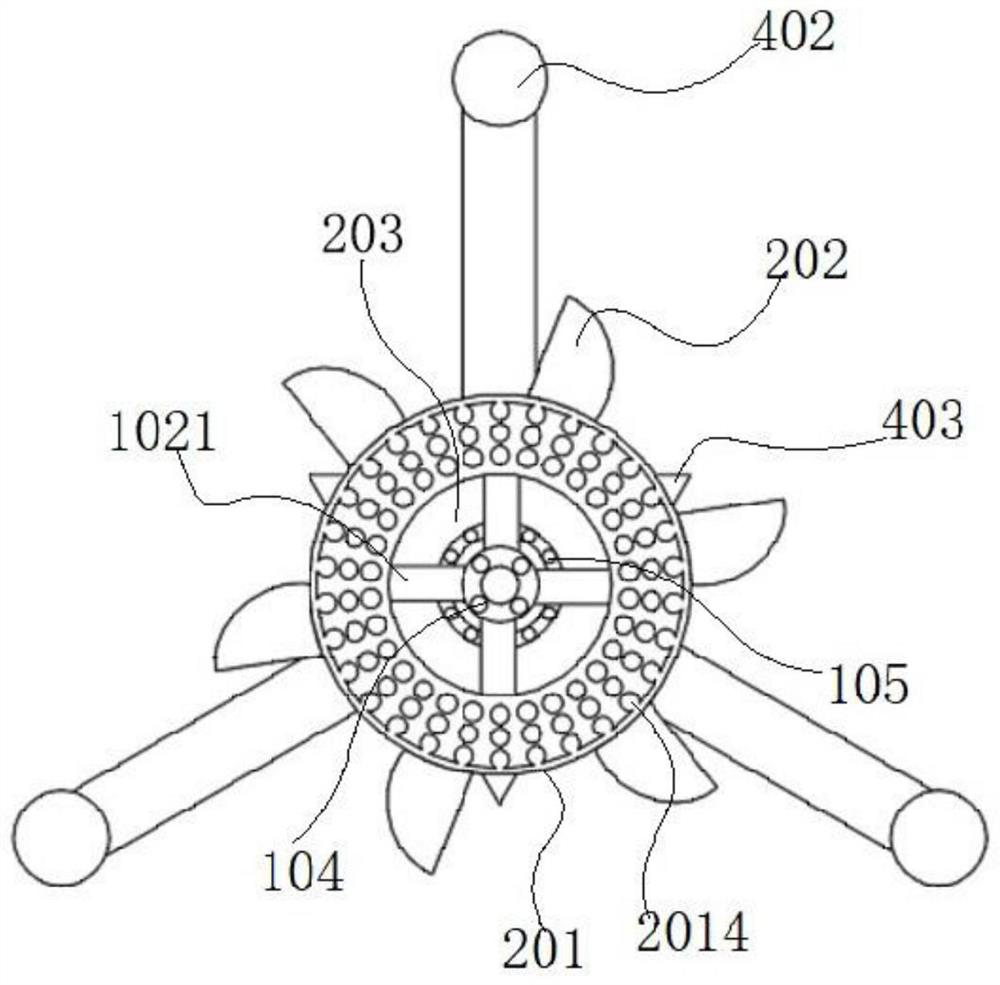

[0052] The gas-liquid conveying unit comprises a primary transmission shaft 101, a secondary conveying shaft 102 and a tertiary conveying shaft 103, the secondary conveying shaft 102 and the tertiary conveying shaft 103 are respectively hollow shafts; the secondary conveying shaft 102 is respectively connected to the primary transmission The shaft 101 and the tertiary delivery shaft 103 form a detachable fixed connection; the secondary delivery shaft 102 and the tertiary delivery shaft 103 are provided with a solution delivery channel 104 and a liquid return channel 105, and the end of the tertiary delivery shaft 103 is provided with an opening. A liquid suction impeller 106 is provided at the opening, and the...

Embodiment 2

[0058] The implementation process of this application: Driven by an external power source, the first-stage transmission shaft 101 drives the gas-liquid contact unit to rotate, and the suction impeller 202 sucks the gas into the gas-liquid exchange chamber 2013 during rotation, and flows through the hollow fiber membrane tube 2014 Surface, heat and mass exchange occurs on the surface of the film tube, and it is discharged through the air discharge hole on the inner wall of the channel 203; the liquid suction impeller 106 rotates, thereby driving the solution to flow upward, and enters the liquid delivery rod 1021 through the solution delivery channel 104, and enters The secondary liquid separation chamber 2012 continues from bottom to top, flows through the interior of the hollow fiber membrane tube 2014 in the gas-liquid exchange chamber 2013 and enters the primary liquid separation chamber 2011, and then is transported through the liquid connected to the primary liquid separati...

Embodiment 3

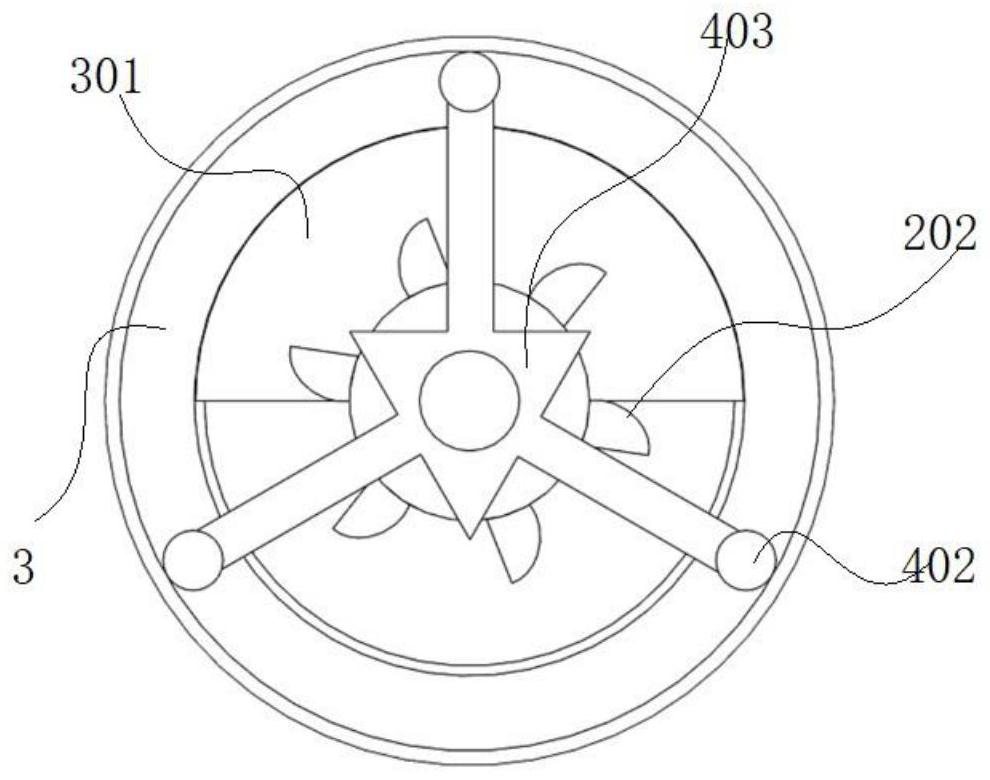

[0060] The rest are consistent with Embodiment 1 or 2; the novel gas-liquid film contactor of the present application also includes a base bracket, and the base bracket includes a positioning base 401, a positioning rod 402 and a positioning plate 403, and the positioning rod 402 is arranged on the positioning base 401, and the positioning plate 403 is provided with two, the liquid storage unit 3 is arranged on the positioning base 401, and the gas-liquid contact unit is arranged between the positioning plates 403, and the positioning plate 403 is provided with a relief hole, and a ball bearing 404 is arranged in the relief hole, and the gas-liquid contact unit is arranged between the positioning plates 403. The liquid delivery unit is fitted with ball bearings 404 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com