A lithium ion battery with square aluminum shell and an assembling method

A technology of lithium-ion batteries and aluminum shells, which is applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc. It can solve problems such as low production efficiency, battery short circuit, and many pole piece failures, and improve safety , The effect of increasing the diversion flow and reducing the heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

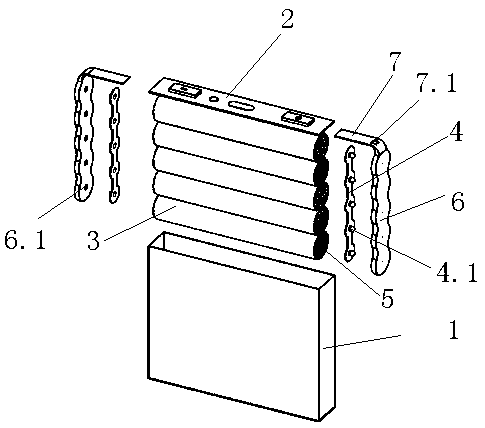

[0043] Embodiment 1: Assembling method with 20120103 lithium-ion battery

[0044] 1. Pole piece winding: the coating adopts continuous coating, and the diaphragm is wrapped with the negative electrode, and the negative electrode is wrapped with the positive electrode in a cylindrical winding method. The width of the pole piece is about 116mm, and the width of the tab is about 6mm. After winding, a cylindrical roll The core is a cylinder with a height of 118mm and a diameter of 19mm after winding. Align the five cores, positive to positive, negative to negative, and bind on both sides of the core with termination tape.

[0045] 2. Rolling core flattening: ultrasonically flatten the white parts on both sides of the winding core in the core binding step, with a power of 800W, the flattening time is about 2 seconds, the flattening depth is about 4-5mm, and the air cylinders on both sides The pressure is 1-1.5MPa.

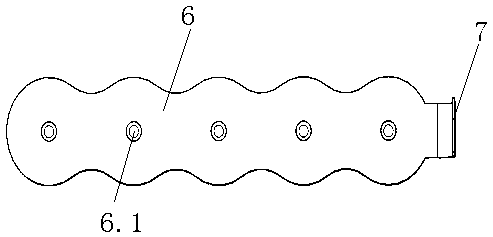

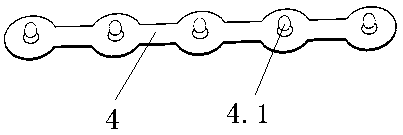

[0046] 3. Welding of the winding core and the conductor: the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com