Zn-doped Ni-MOF self-supporting combined electrode and preparation method and application thereof

A composite electrode, self-supporting technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of complex process technology, poor electrode conductivity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

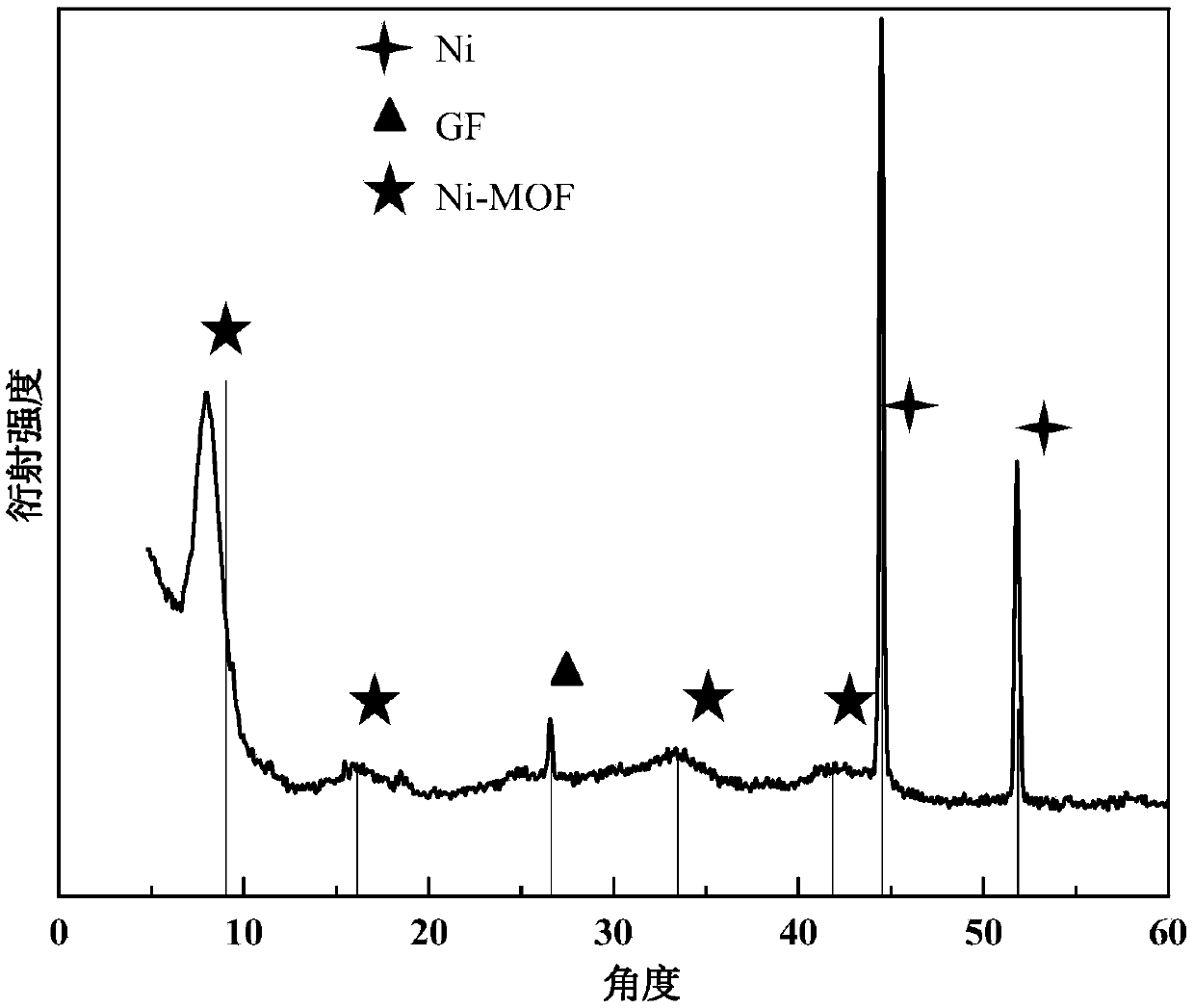

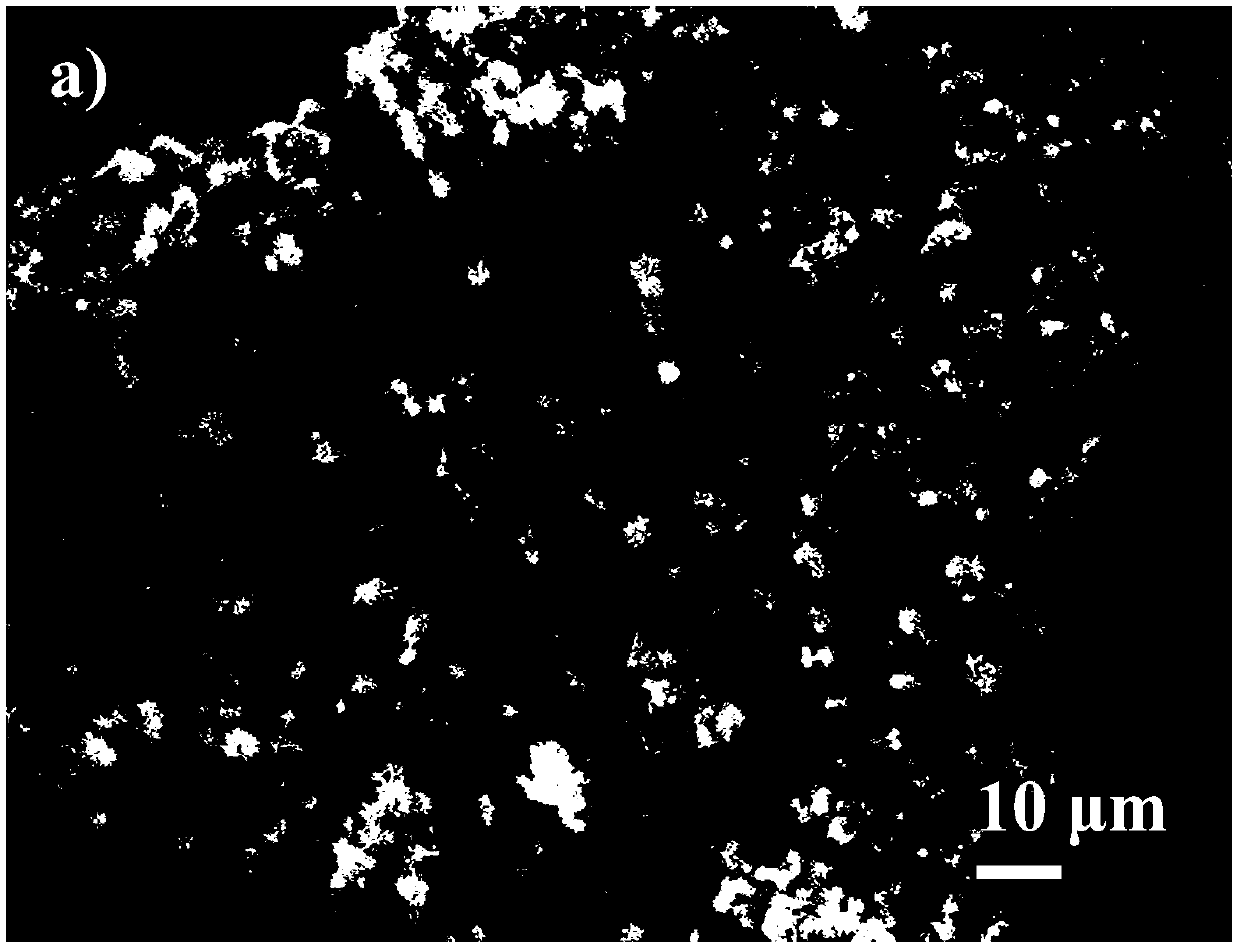

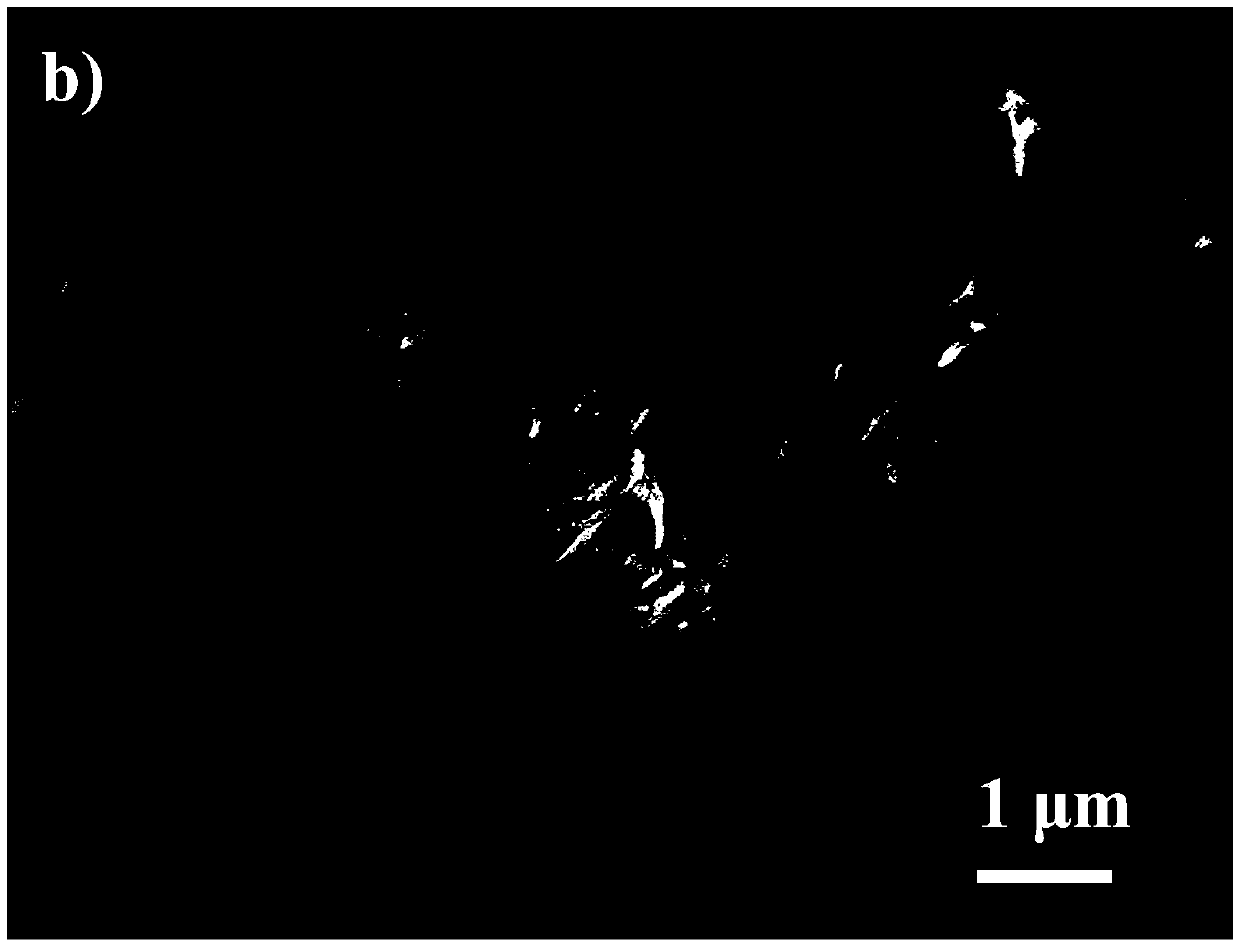

Image

Examples

Embodiment 1

[0016] (1) Cut foam nickel (NF) into The shape (1×1×1.5cm), put it into a beaker, add acetone, and sonicate in an ultrasonic cleaner for 10 minutes. Then, put it in a vacuum drying oven at 80°C for 24 hours;

[0017] (2) Place the NF in (1) in a crucible, then put the crucible into a high-temperature tube furnace, evacuate the tube furnace, and feed Ar (200 sccm) and H 2 (100sccm), the high-temperature tube furnace program is set to heat up to 1000°C at a rate of 50°Cm, and CH 4 (100sccm), followed by constant temperature for 1h, after reaching the time, turn off H 2 and CH 4 , after cooling down to room temperature naturally, turn off Ar to get nickel foam / graphene foam (NF / GF electrode)

[0018] (3) Take 6.5ml DMF and 4ml ethylene glycol, form a mixed solution in a beaker, add 0.024g terephthalic acid, 0.04g nickel nitrate (Ni(NO3) 2 6H 2 O) and 0.044g of Zn(NO3) 2 , stirred at room temperature for 1 hour with a magnetic stirrer.

[0019] (4) the NF-GF electrode tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com