Ferroferric oxide/single-wall carbon nano-angle composite electrode material and preparation method thereof

A single-wall carbon nano-horn and ferric oxide technology, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology, etc. Effects of Capacitive Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

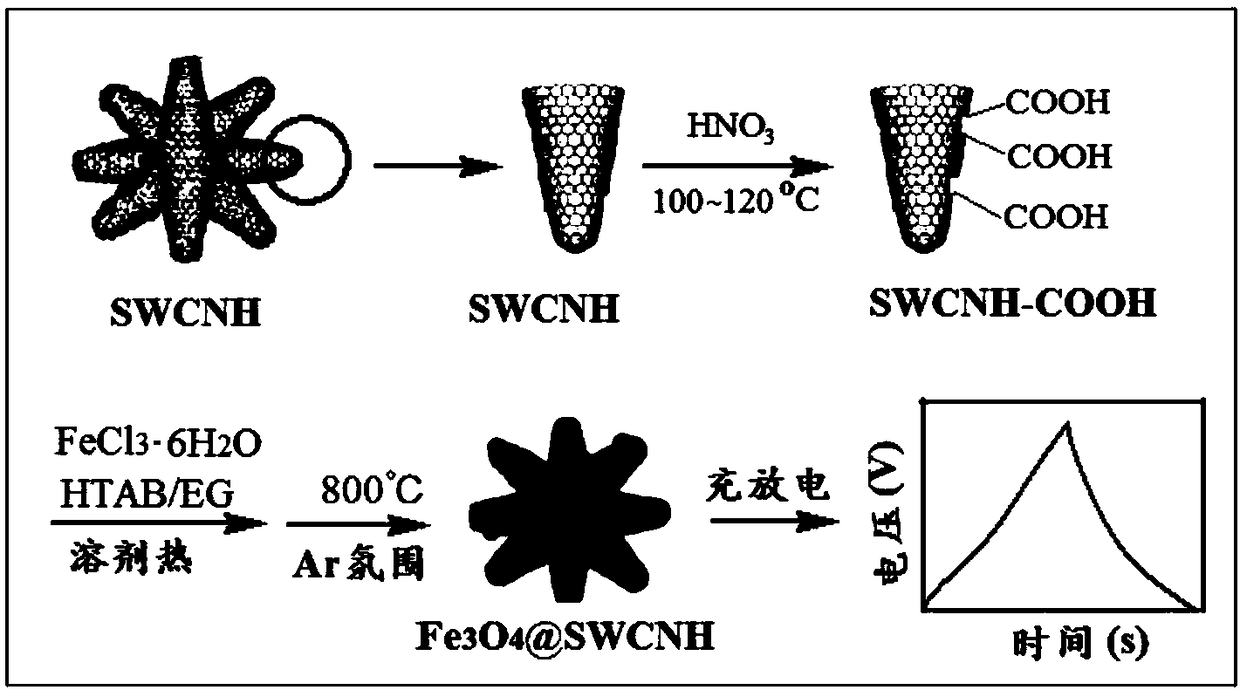

[0048] The preparation of described SWCNH-COOH is:

[0049] Disperse SWCNH into nitric acid solution, heat and reflux at 100-120°C for 12-24 hours, centrifuge the reaction solution after the reaction is completed, wash and filter repeatedly with deionized water until the filtrate becomes neutral, then vacuum at 80-90°C Dry to obtain SWCNH-COOH, and then disperse SWCNH-COOH in ethylene glycol to form a 0.5-1.0 mg / mL SWCNH-COOH dispersion.

[0050] The SWCNH-COOH and Fe 3 o 4 The nanocomposite of is:

[0051] A. Add 1.35g of FeCl to 100mL of SWCNH-COOH / EG dispersion 3 ·6H 2 O and 0.5g of cetyltrimethylammonium bromide, magnetically stirred at 50-60°C for 2-5h;

[0052] B. After the mixture is evenly dispersed, transfer the obtained mixed solution to the reaction kettle, and then place it at 180°C for constant temperature reaction for 12-18 hours;

[0053] C. After the reaction is completed, cool to room temperature, open the reaction kettle, centrifuge the composite, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com