A method for predicting the thickness of a uniform piezoelectric electrode scale layer of a converter valve based on an electrode reaction

A technology of electrode reaction and electrode scale, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as scale layer shedding, large manpower and material resources, and outage of converter stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

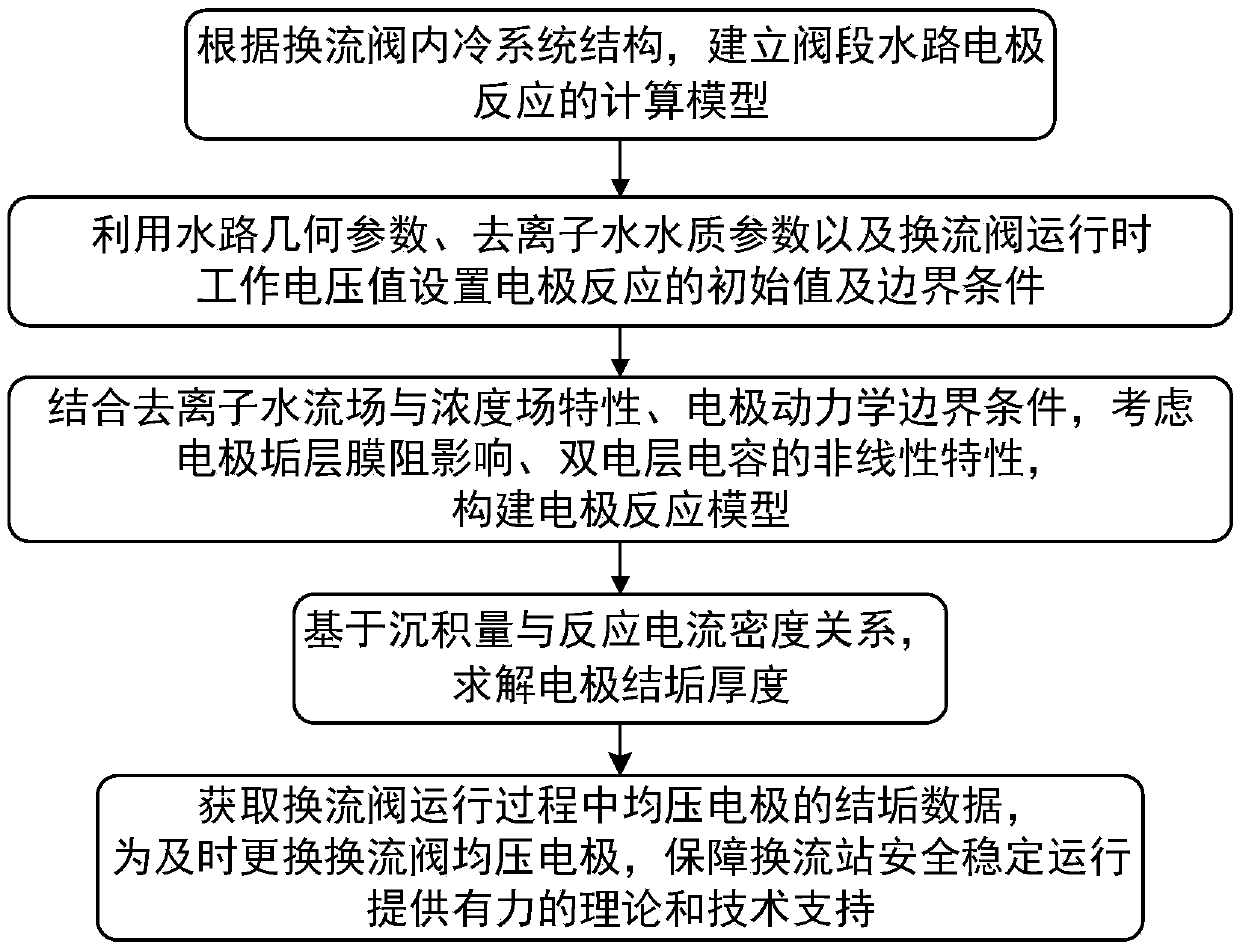

[0054] This embodiment provides a method for predicting the scale layer thickness of the voltage equalizing electrode of the valve cooling system based on the electrode reaction, such as figure 1 shown, including the following steps:

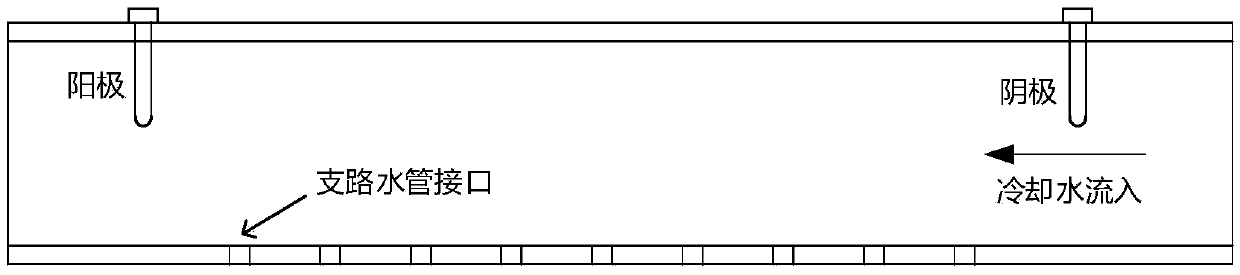

[0055] Step 1: According to the internal cooling system structure of the valve section of the converter valve adopting parallel waterway cooling in a converter station, determine the physical model structure of the waterway electrode reaction of the valve section, and then establish the calculation of the valve section waterway electrode reaction according to the operating conditions Model;

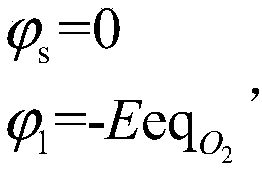

[0056] Step 2: Set the initial values and boundary conditions of the electrode potential and the deionized water potential by using the geometric parameters of the waterway, the water quality parameters of the deionized water, and the operating voltage value of the converter valve;

[0057] Step 3: Combining the characteristics of the flow field and conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com