A process parameter optimization method based on die forging die wear

A technology for process parameter optimization and process parameter application in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve problems such as reducing the production quality of forging products and affecting product production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

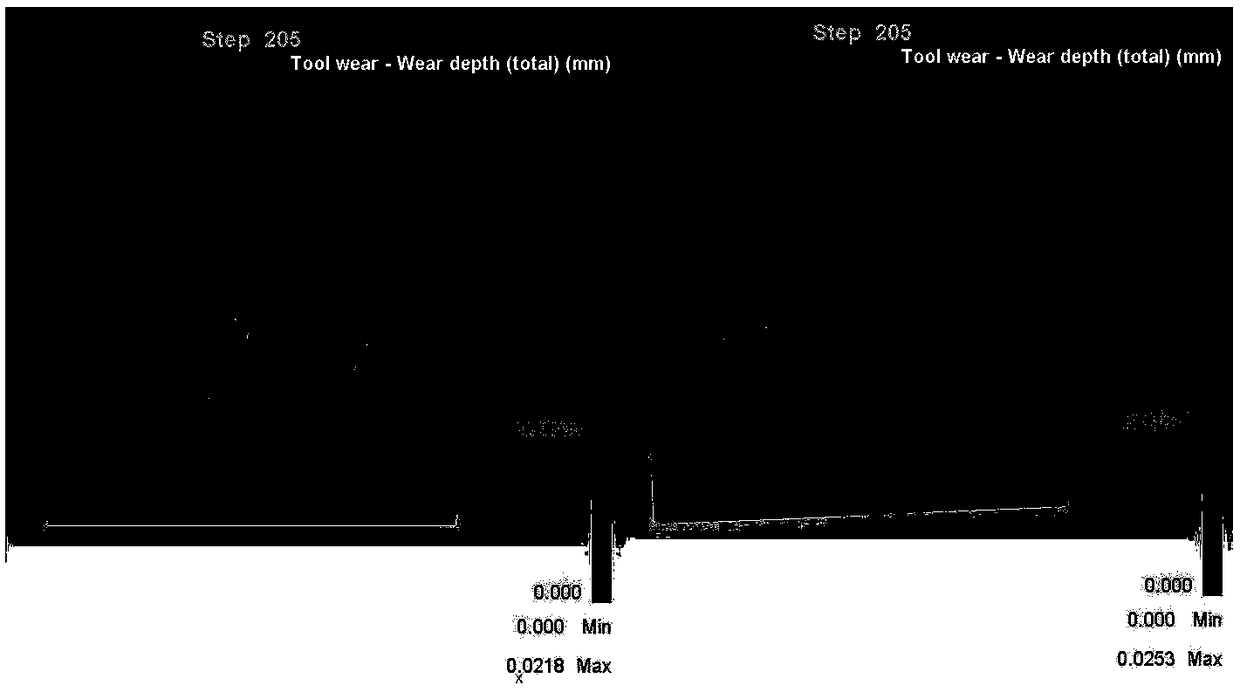

[0057] The present invention takes the actual production process requirements as an example: the initial blank temperature range is 900-1200°C, the initial mold temperature range is 250-400°C, and the punching speed range of the upper die is 300-600mm / s. Under the requirements of the above-mentioned die forging process, an optimal solution of process parameters is proposed for die wear optimization.

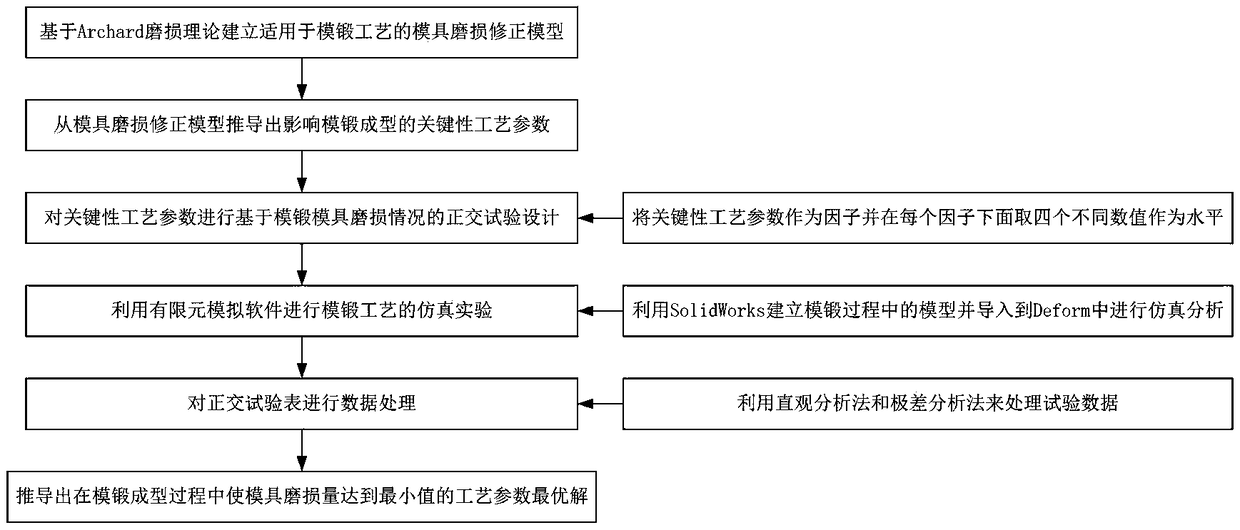

[0058] Specifically include the following steps:

[0059] Step 1 is based on the Archard wear theory, establishes a die wear correction model suitable for the die forging process; step 1.1 establishes the Archard wear model;

[0060] Due to the different settings of process parameters, the temperature, equivalent stress distribution, metal flow rate and other results during the die forging process will also change accordingly. Therefore, the setting of process parameters can indirectly affect the wear of the mold. In actual production, these process parameters are considered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com