A preparation method of electronically controlled smart film based on liquid crystal/epoxy-thiol polymer composite material

A composite material and polymer technology, which is applied in the field of preparation of electronically controlled smart films based on liquid crystal/epoxy-thiol polymer composite materials, can solve the problems of unfavorable PDLC production efficiency, high temperature, and long time for complete curing , to achieve the effects of improving practical value, improving production efficiency, and making the preparation process simple and operable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Mix NDGA / PGDE / Capcure 3800 / E8 / DMP-30 according to the mass fraction ratio in Table 1. After fully stirring evenly, pour it into a liquid crystal cell made of two pieces of conductive glass coated with indium tin oxide , the thickness of the liquid crystal cell is controlled to 20.0um. Afterwards, the sample was placed on a hot stage and cured at 333.15K for 2 hours. After the thermally polymerized monomer was cured, an electronically controlled smart film based on liquid crystal / epoxy-thiol polymer composites could be prepared.

[0041] The composition of sample in the embodiment 1-3 of table 1

[0042]

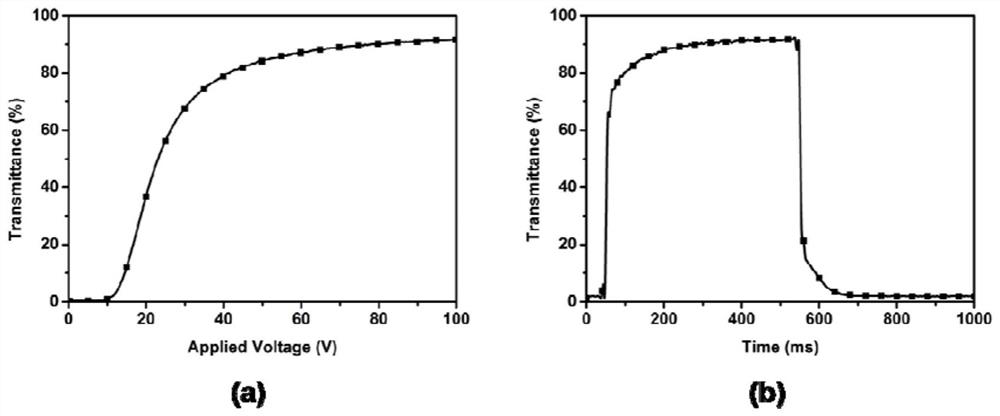

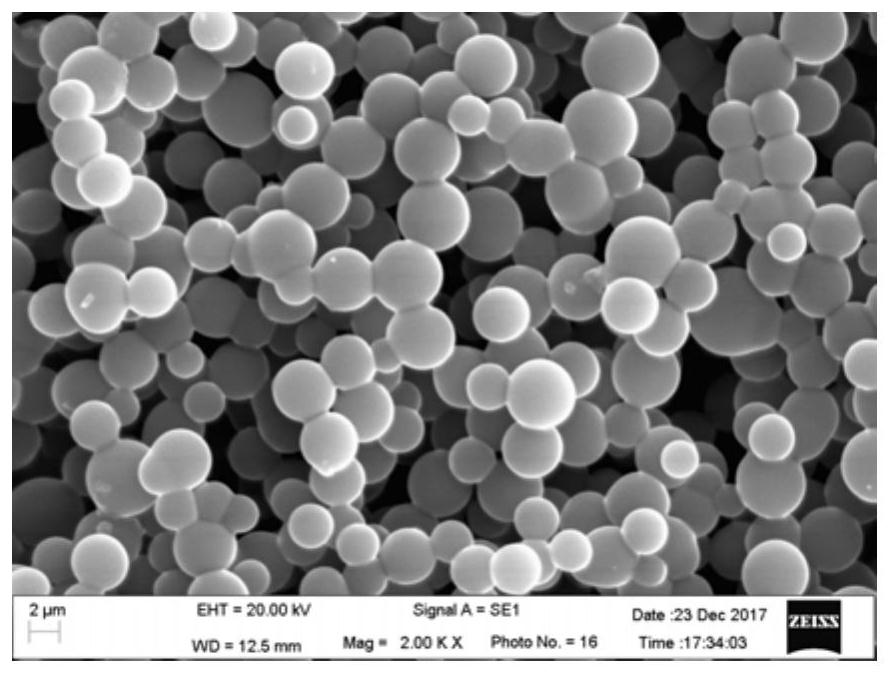

[0043] Measure the electro-optical performance curve of the PDLC film prepared above with a liquid crystal comprehensive parameter tester, such as figure 2 shown. The polymer network of PDLC was observed with a scanning electron microscope (SEM), such as image 3 shown.

[0044] The main electro-optic properties of the electronically controlled smart film prepar...

Embodiment 2

[0049] Mix NDGA / PGDE / Capcure 3800 / E8 / DMP-30 according to the mass fraction ratio in Table 1. After fully stirring evenly, pour it into a liquid crystal cell made of two pieces of conductive glass coated with indium tin oxide , the thickness of the liquid crystal cell is controlled to 20.0um. After that, the sample was placed on a hot stage and cured at 313.15K for 2 hours. After the thermally polymerized monomer was cured, an electronically controlled smart film based on liquid crystal / epoxy-thiol polymer composites could be prepared.

[0050] Measure the electro-optical performance curve of the PDLC film prepared above with a liquid crystal comprehensive parameter tester, such as Figure 4 shown. The polymer network of PDLC was observed with a scanning electron microscope (SEM), such as Figure 5 shown.

[0051] The main electro-optic properties of the electronically controlled smart film prepared in Example 2 are shown in Table 3.

[0052] Table 3 Main electro-optic prop...

Embodiment 3

[0056] Mix NDGA / PGDE / Capcure 3800 / E8 / DMP-30 according to the mass fraction ratio in Table 1. After fully stirring evenly, pour it into a liquid crystal cell made of two pieces of conductive glass coated with indium tin oxide , the thickness of the liquid crystal cell is controlled to 20.0um. Afterwards, the sample was placed on a hot stage and cured at 353.15K for 2 hours. After the thermally polymerized monomer was cured, an electronically controlled smart film based on liquid crystal / epoxy-thiol polymer composites could be prepared.

[0057] Measure the electro-optical performance curve of the PDLC film prepared above with a liquid crystal comprehensive parameter tester, such as Image 6 shown. The polymer network of PDLC was observed with a scanning electron microscope (SEM), such as Figure 7 shown.

[0058] The main electro-optical properties of the electronically controlled smart film prepared in Example 3 are shown in Table 4.

[0059] The main electro-optical prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com