Tool detection method, detection device and toolbox

A detection method and detection device technology, applied in the field of tools, can solve the problems of time-consuming and laborious, lost tools, and left EMUs, etc., and achieve the effects of convenient operation, saving search time, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

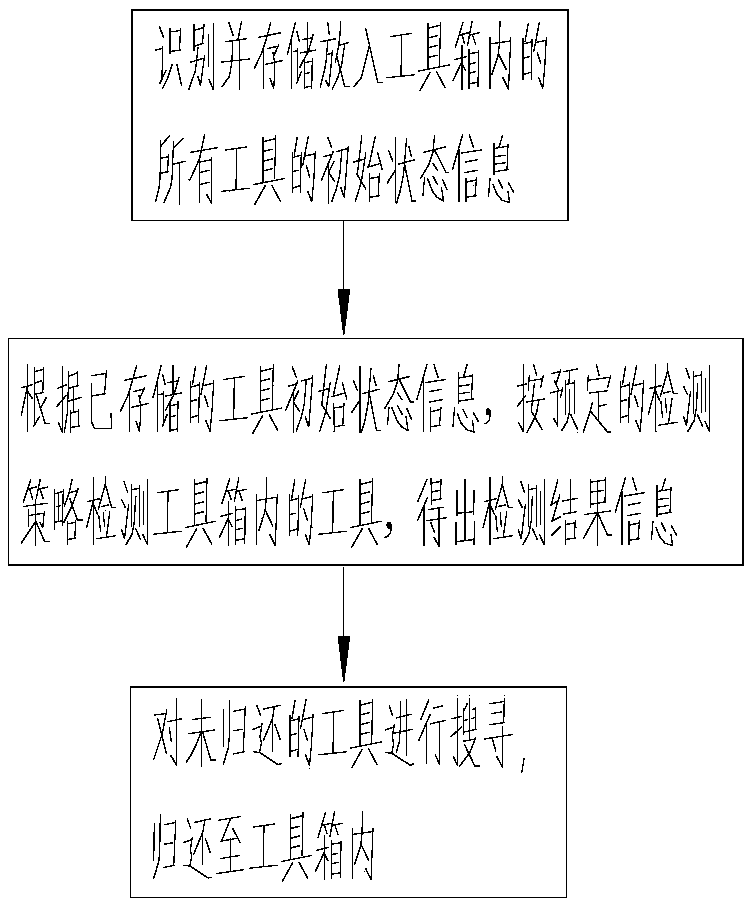

[0036] Such as figure 1 As shown, a tool detection method provided in this embodiment specifically includes the following steps:

[0037] Step 1, identify and store the initial state information of all the tools put into the toolbox;

[0038] Step 2, according to the stored initial state information of the tool, detect the tool in the toolbox according to a predetermined detection strategy, and obtain the detection result information;

[0039] Step 3: Search for unreturned tools.

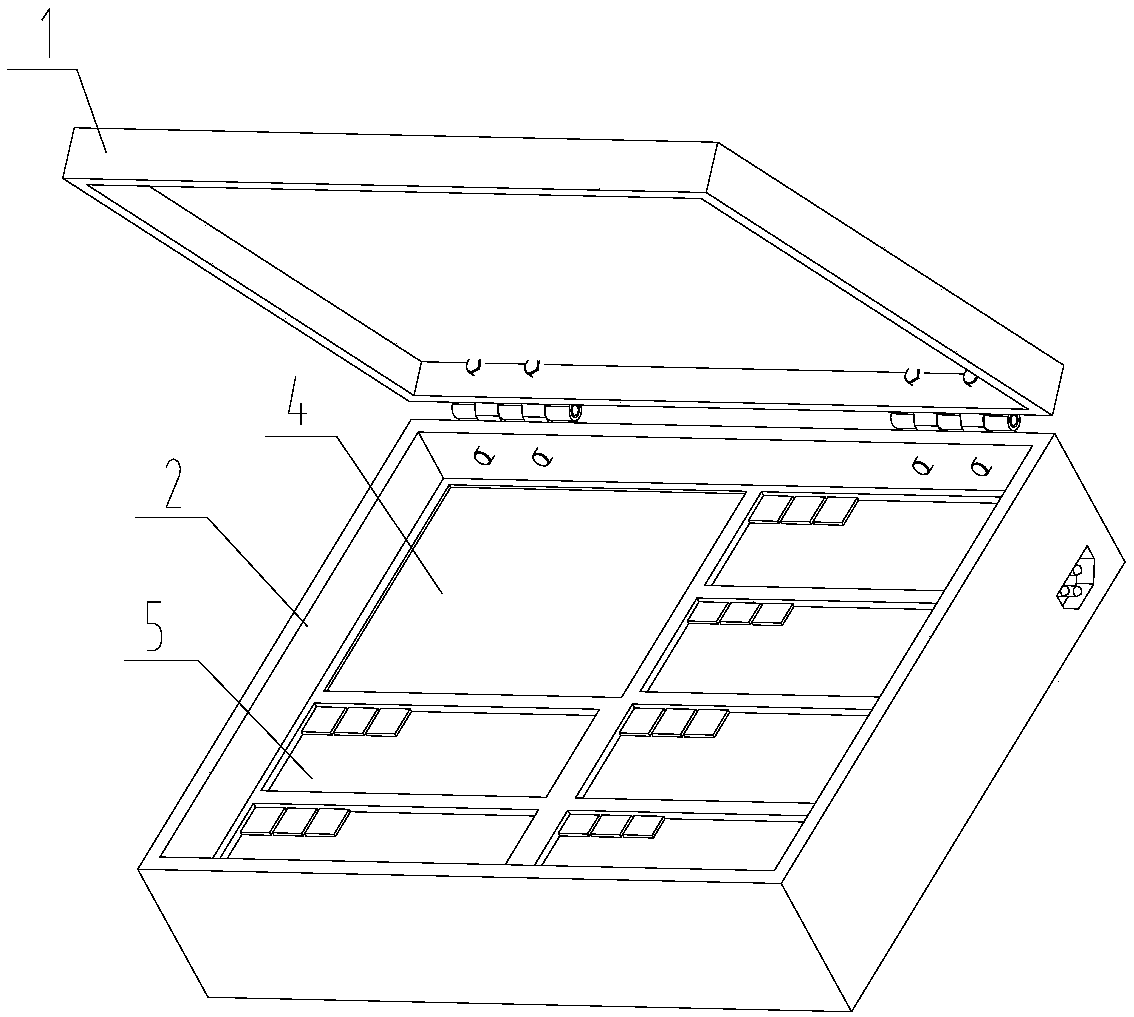

[0040] Wherein, in step 1, the initial state information includes at least the total number of tools put into the toolbox, the identity information of each tool and the location information of each tool stored in the toolbox.

[0041] An RFID electronic tag for identification is pasted on each tool, and the identity information of the tool is stored on the electronic tag, including the name, model, purpose, etc. of the tool. In this embodiment, in order to facilitate the user to manage the tools ...

Embodiment 2

[0054] The difference from Embodiment 1 is that in this embodiment, the initial status information of the tools in the toolbox includes the total number of tools put into the toolbox and the identity information of each tool. The initial state information acquisition module of the PLC controller only recognizes and records the total number of tools put into the toolbox and the identity information of each tool, but does not recognize the location information of the tools, that is, the location when the tools are initially stored is different from the location where they are returned. A unique correspondence needs to be established.

[0055] In this embodiment, the detection strategy also includes three aspects: one is to detect whether all the tools belonging to the toolbox are returned, that is, whether the number of tools in the toolbox after returning is consistent with the number of tools at the time of initial storage; , to detect whether the identity information of each ...

Embodiment 3

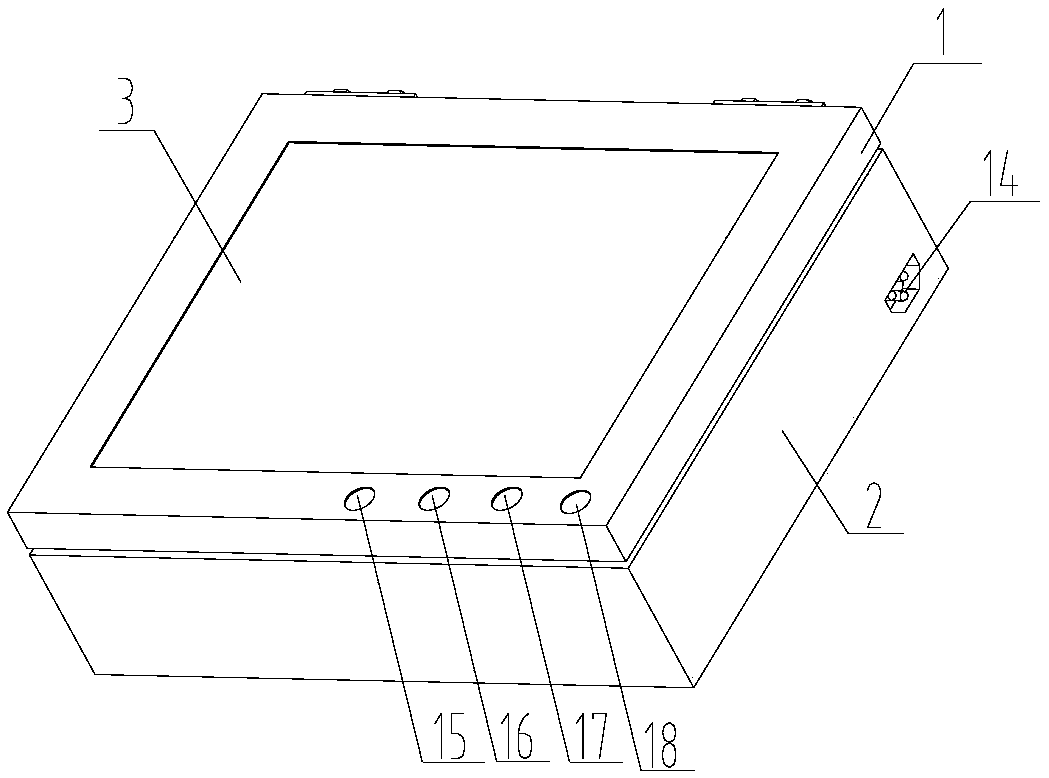

[0060] This embodiment provides a detection device capable of implementing the tool detection methods provided in Embodiment 1 and Embodiment 2. The detection device includes an initial state information acquisition module, a tool detection module, a search module and a display module.

[0061] The initial state information acquisition module is used to identify and store the initial state information of all the tools put into the toolbox. The tool detection module is used to detect the tools in the toolbox according to the predetermined detection strategy according to the stored initial state information of the tools, and obtain the detection result information. Search module for searching for unreturned tools. The display module is used to display the initial state information and detection result information of the tool. The initial state information acquisition module and the tool detection module are integrated in the PLC controller.

[0062] Wherein, the display modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com