Oxidation device containing combined porous medium charge and loading method thereof

A porous medium and oxidation device technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of reducing coal mine gas purification efficiency and heat energy recovery effect, reducing catalyst catalytic efficiency, etc., to reduce availability and increase heat energy Utilization efficiency, the effect of increasing the output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

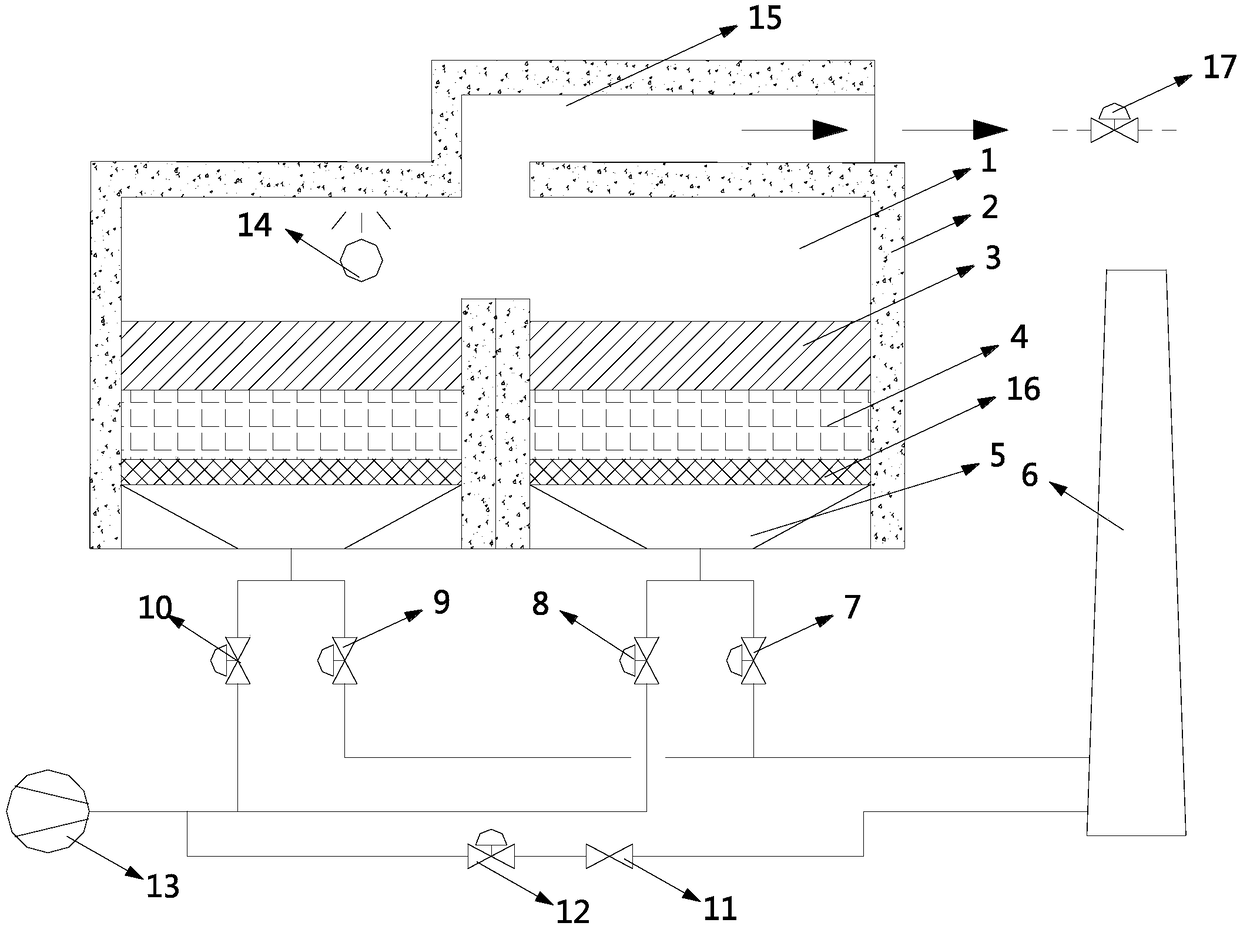

[0027] The reference signs in the accompanying drawings of the specification include:

[0028] Combustion chamber 1, heat storage incinerator 2, catalytic coating 3, heat storage layer 4, air intake chamber 5, chimney 6, second air outlet valve 7, second air intake valve 8, first air outlet valve 9, first air inlet Gas valve 10, manual gate valve 11, pneumatic stop valve 12, fan 13, burner 14, flue gas channel 15, water absorption layer 16, high temperature flue gas regulating valve 17.

[0029] Such as figure 1 The shown oxidation device containing the combined porous medium filling includes a regenerative incinerator 2, a fan 13 and a chimney 6. The inner layer of the shell of the regenerative incinerator 2 is made of steel alloy, and the outer layer is made of high alumina. The thickness of the steel alloy is 1 to 2mm, and the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com