A new energy boiler with feeding function

A new energy and functional technology, which is applied in the direction of solid fuel combustion, furnace grate, double-layer furnace grate, etc., can solve the problems of inability to realize automatic feeding, single boiler structure, and inability to realize automatic ash discharge, so as to save manpower and improve The effect of work efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

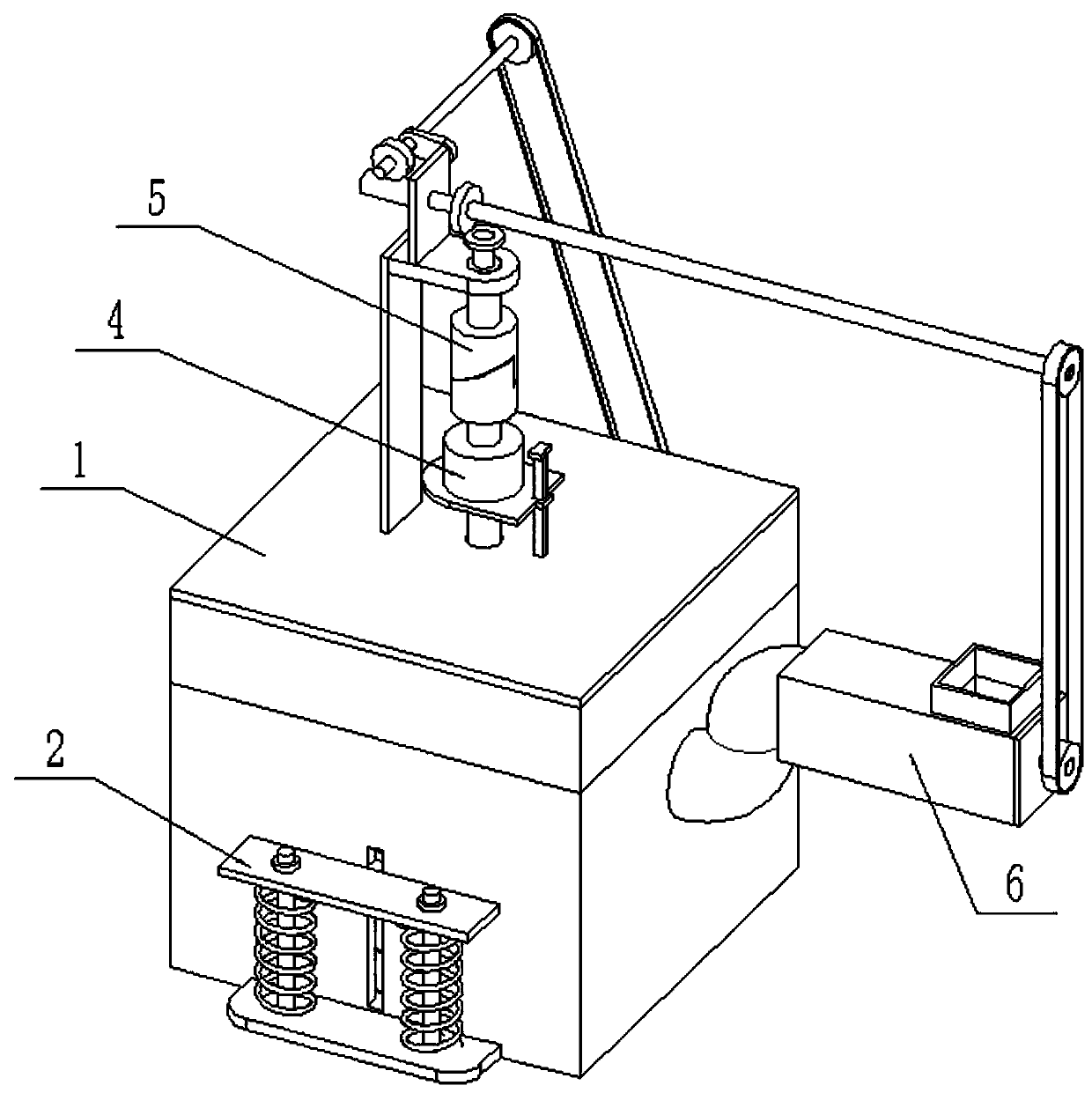

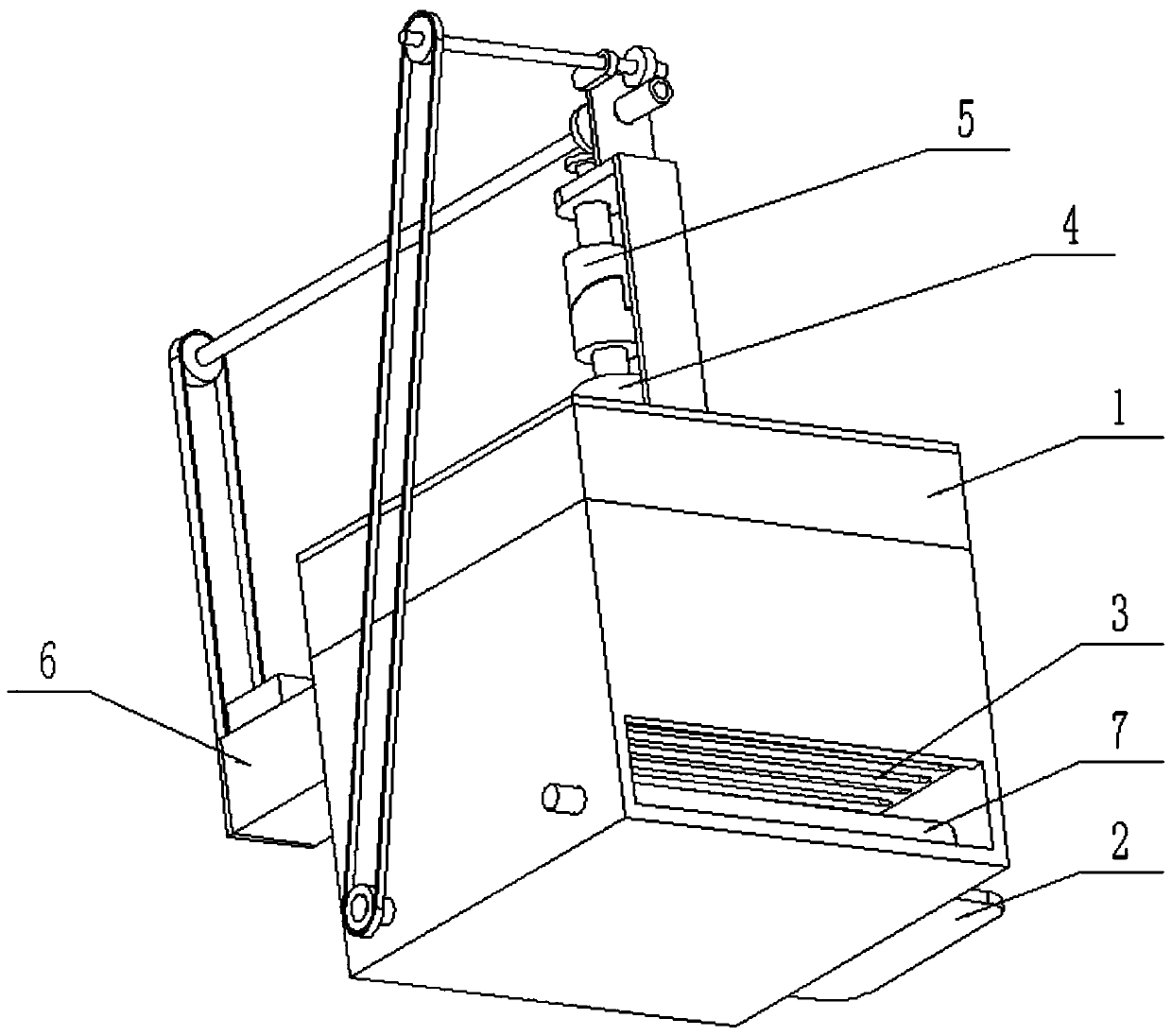

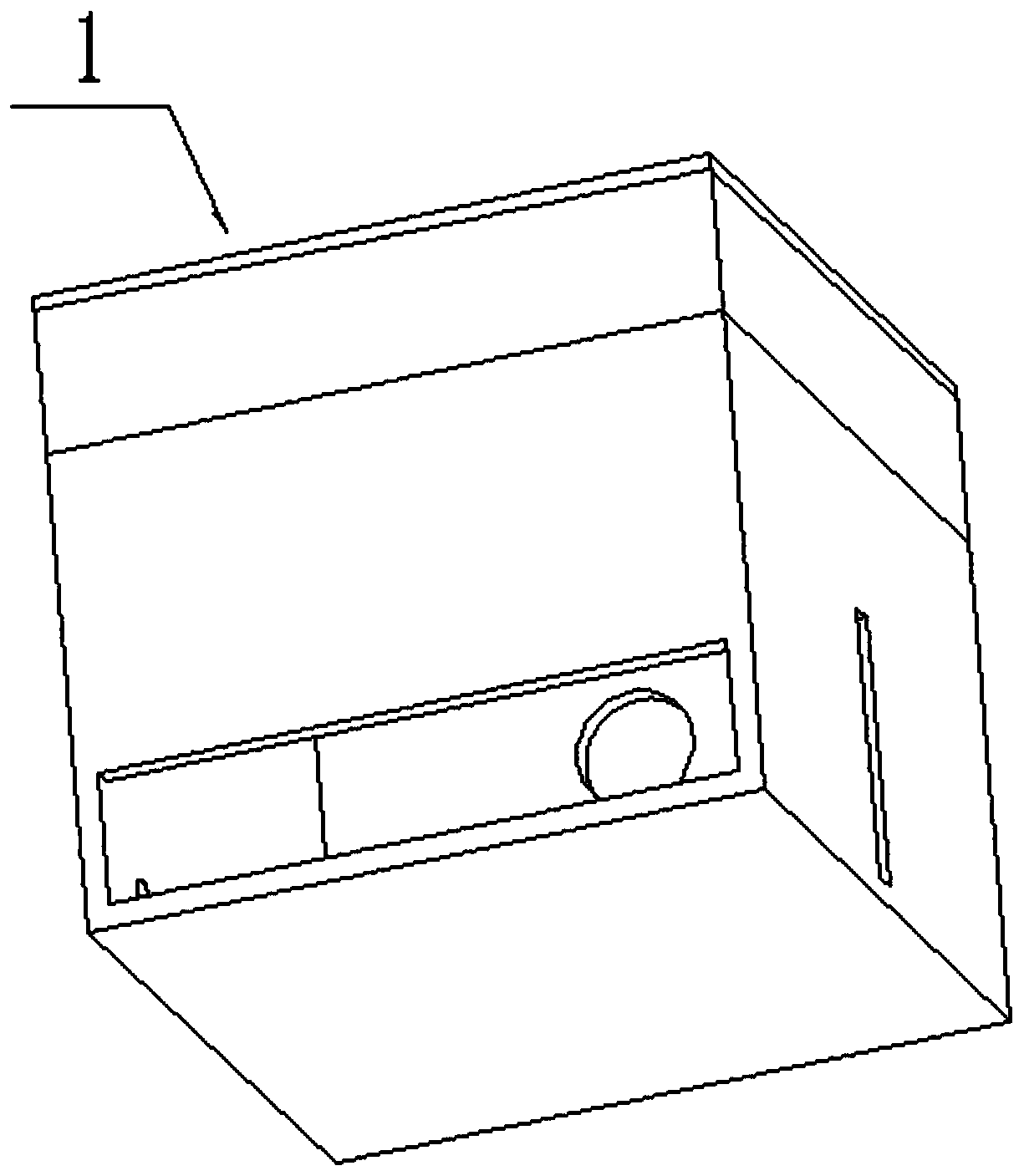

[0025] Such as Figure 1-9 As shown, a new energy boiler with feeding function includes a boiler body 1, a movable grate assembly 2, a fixed grate 3, a motor drive device 4, a transmission device 5, a feeding device 6 and an ash discharge device 7. The fire grate assembly 2, the fixed fire grate 3 and the ash discharge device 7 are sequentially connected to the inner side of the boiler body 1 from top to bottom; On the top surface of the boiler body 1; the upper end of the motor drive device 4 is connected to the transmission device 5; the transmission device 5 is connected to the feeding device 6 and the ash discharge device 7; the charging device 6 is fixedly connected and communicated with the boiler The upper end of the rear side of the body 1; the level of the charging device 6 is higher than the level of the movable grate assembly 2; the lower end of the front side of the boiler body 1 is provided with an ash discharge port, and the ash discharge port is facing the ash d...

specific Embodiment approach 2

[0027] Such as Figure 1-9As shown, the movable grate assembly 2 includes a movable grate body 2-1, a lifting push rod 2-2, a rectangular slider 2-3, a movable plate 2-4, a fixed plate 2-5, and a compression spring 2-6 , spring shaft 2-7 and limit ring 2-8; the middle end of the movable grate body 2-1 is fixedly connected to the lifting push rod 2-2, and the lifting push rod 2-2 is slidably connected to the top of the boiler body 1 On the surface, the top of the lifting push rod 2-2 is fixedly connected to the motor drive device 4; the movable grate body 2-1 is fixedly connected to the movable plate 2-4 through a rectangular slider 2-3; the movable grate body 2- 1. The clearance fit is connected to the inner surface of the boiler body 1, and the rectangular slider 2-3 is slidably connected to the vertical chute on the side of the boiler body 1; the movable plate 2-4 is slidably fitted with two spring shafts 2 -7, the lower ends of the two spring shafts 2-7 are fixedly connect...

specific Embodiment approach 3

[0030] Such as Figure 1-9 As shown, the motor drive device 4 includes a drive motor 4-1, a drive shaft 4-2, a linkage wheel 14-3, a motor seat 4-4 and a rectangular guide rod 4-5; the drive motor 4-1 is fixedly connected On the motor base 4-4, the rectangular guide rod 4-5 is slidably connected to the motor base 4-4, and the lower end of the rectangular guide rod 4-5 is fixedly connected to the boiler body 1; the output of the drive motor 4-1 The end is connected to the drive shaft 4-2 through a coupling; the drive shaft 4-2 is fixedly connected to the linkage wheel I4-3; the linkage wheel I4-3 is connected to the transmission device 5 through transmission. When the motor drive device 4 is working, the drive motor 4-1 drives the drive shaft 4-2 to rotate, and the drive shaft 4-2 drives the interlocking wheel I4-3 to rotate. When the interlocking wheel I4-3 contacts the transmission device 5, it can Drive transmission device 5 to work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com