Thermoelectric decoupling type thermal energy storage heat and power combined supply system

A technology of combined heat and power supply and thermal energy storage, which is applied in the direction of combined combustion mitigation, steam engine installation, steam application, etc., can solve the problems of inability to store heat in the system and low energy conversion efficiency, so as to ensure reliability, improve reliability, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

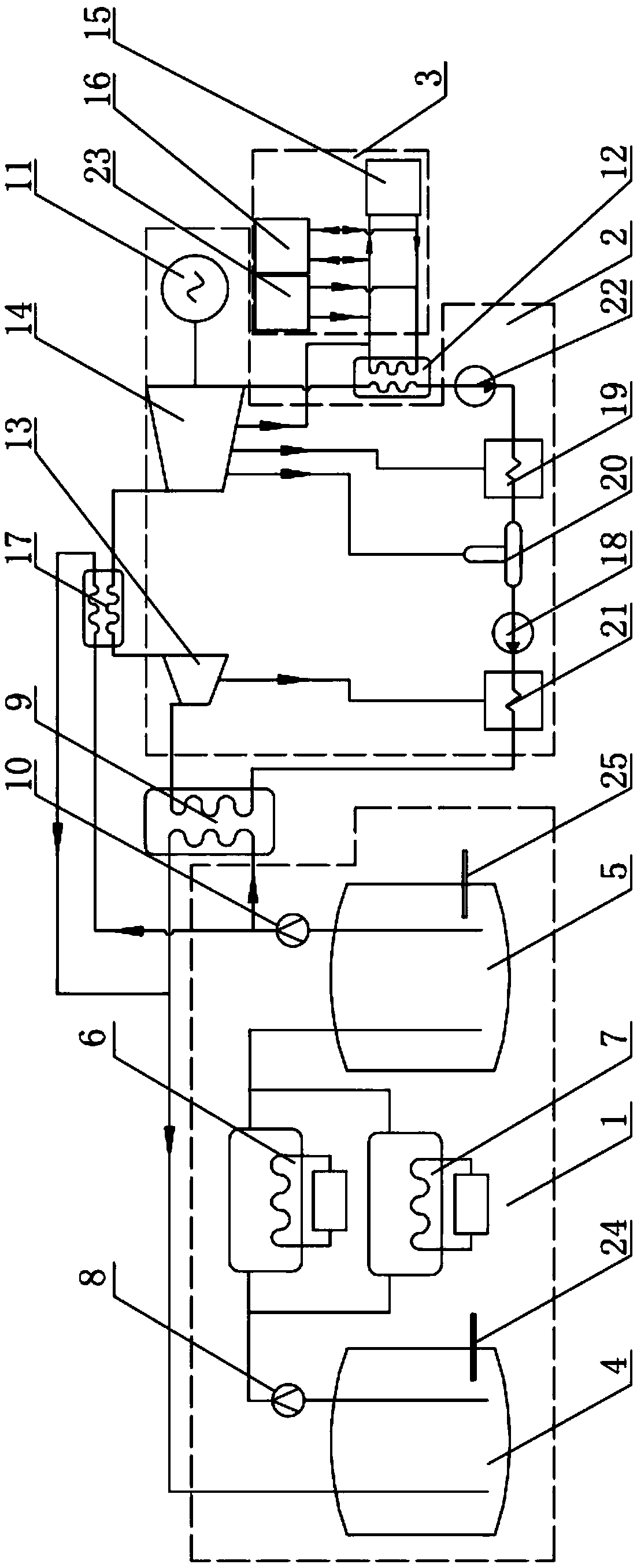

[0015] A thermoelectric decoupling thermal energy storage cogeneration system of the present invention includes an energy storage power station unit 1 , a steam turbine unit 2 and a heat supply unit 3 .

[0016] The energy storage power station unit 1 includes a low-temperature medium tank 4, a high-temperature medium tank 5, an electric heater 6, and a gas heater 7. Both the low-temperature medium tank 4 and the high-temperature medium tank 5 store heat storage medium; the low-temperature medium tank 4 A low-temperature medium output pipeline is connected, and the low-temperature medium output pipeline passes through the heating ends of the electric heater 6 and the gas heater 7 respectively and then enters the high-temperature medium tank 5; the low-temperature medium output pipeline is provided with a cold medium pump 8 for For pumping low-temperature heat storage medium;

[0017] The high-temperature medium tank 5 is connected with a high-temperature medium output pipeline...

specific Embodiment approach 2

[0025] The difference between the second embodiment and the first embodiment is that the heat storage medium is molten salt.

[0026] The molten salt can use NaNO with a mass fraction of 60% respectively 3 and 40% KNO 3 The binary molten salt made by mixing, the melting point of the binary molten salt is about 220°C, and the upper limit expansion temperature is 500°C; or KNO with a mass fraction of 53% respectively 3 , 40% NaNO 2 and 7% NaNO 3 Mixed ternary molten salt. The melting point of ternary molten salt is 142°C and the vaporization point is 500°C. Sodium nitrite will decompose slowly above 450°C, but the working temperature of the general system is within 250-350°C.

specific Embodiment approach 3

[0027] The difference between the third embodiment and the first embodiment is that a high-pressure exhaust steam pipeline is connected between the high-pressure cylinder 13 of the steam turbine and the medium-low pressure cylinder 14 of the steam turbine; There is a reheater 17, and the high-temperature medium output pipeline also performs heat exchange with the high-pressure exhaust pipeline through the reheater 17.

[0028] The high-temperature medium output pipeline is divided into two paths, one path returns to the low-temperature medium tank 4 after passing through the steam generator 9, and the other path returns to the low-temperature medium tank 4 after passing through the reheater 17.

[0029] After the steam does work in the high-pressure cylinder 13 of the steam turbine, and then passes through the reheater 17 to exchange heat with the high-temperature heat storage medium from the high-temperature medium tank 5, the steam enters the medium-low pressure cylinder 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com