Steam turbine chassis and steam turbine

A steam turbine and chassis technology, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve problems such as difficult adjustment of the center, and achieve the effects of reducing difficulty, simple and practical processing and installation processes, and shortening processing cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

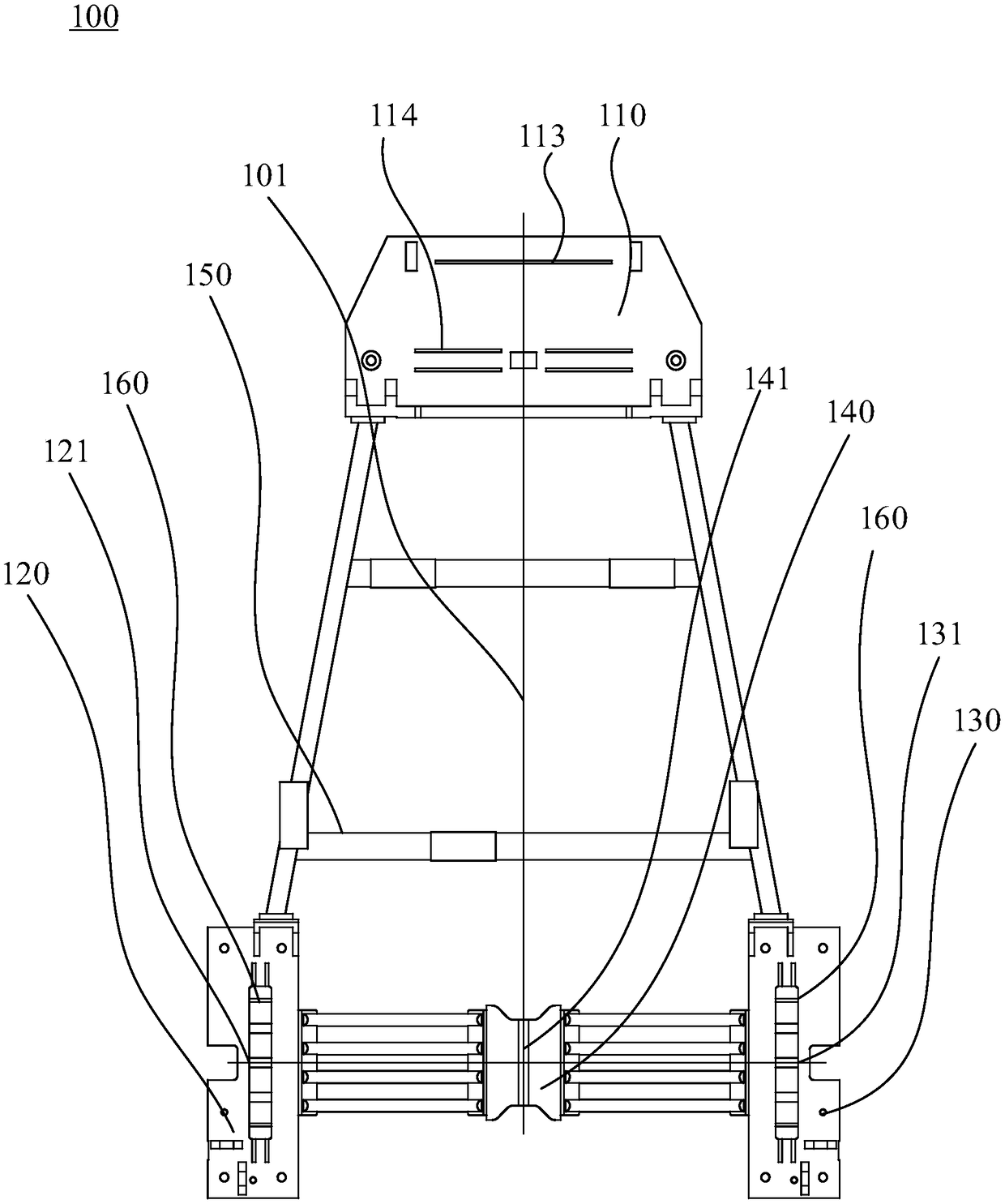

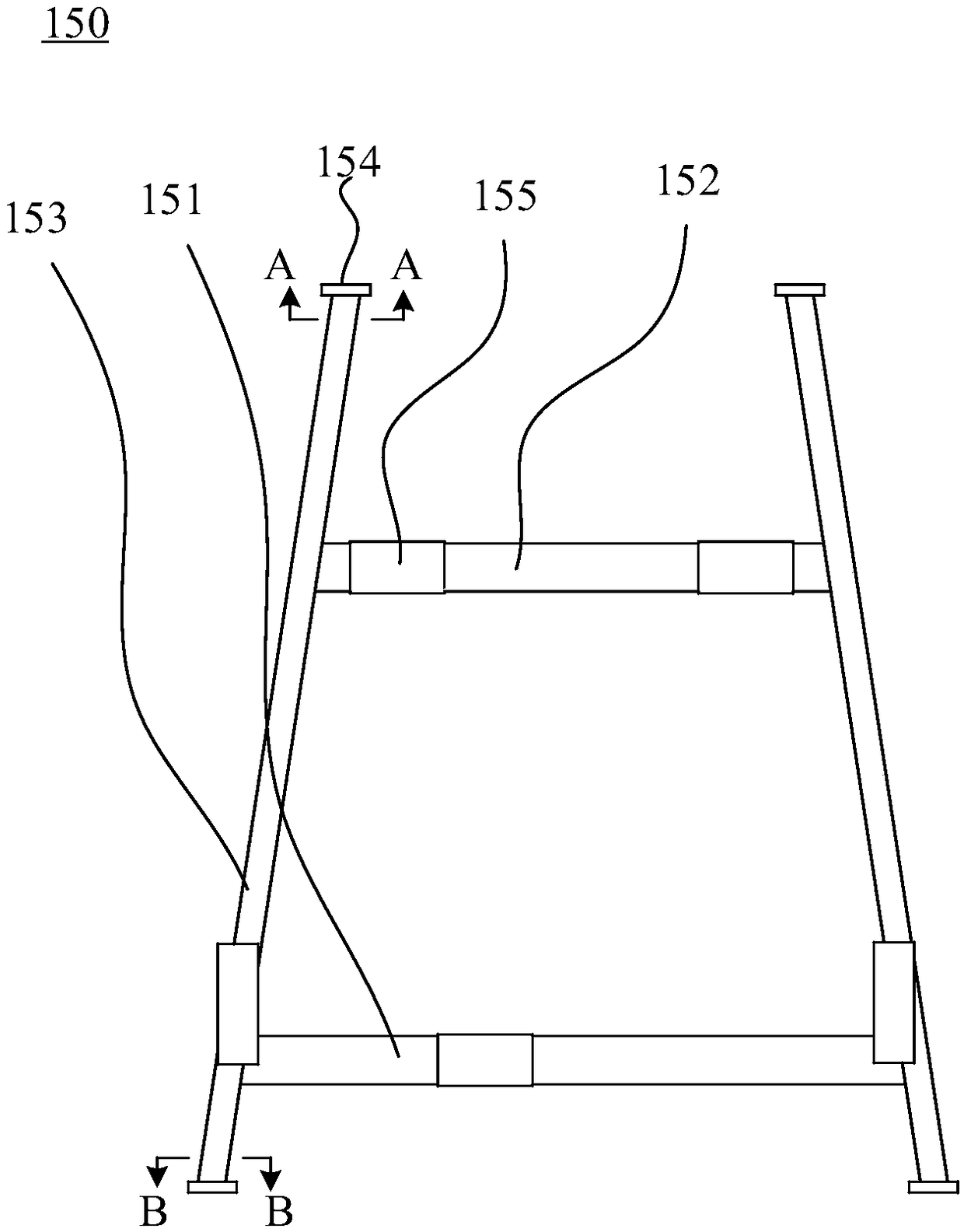

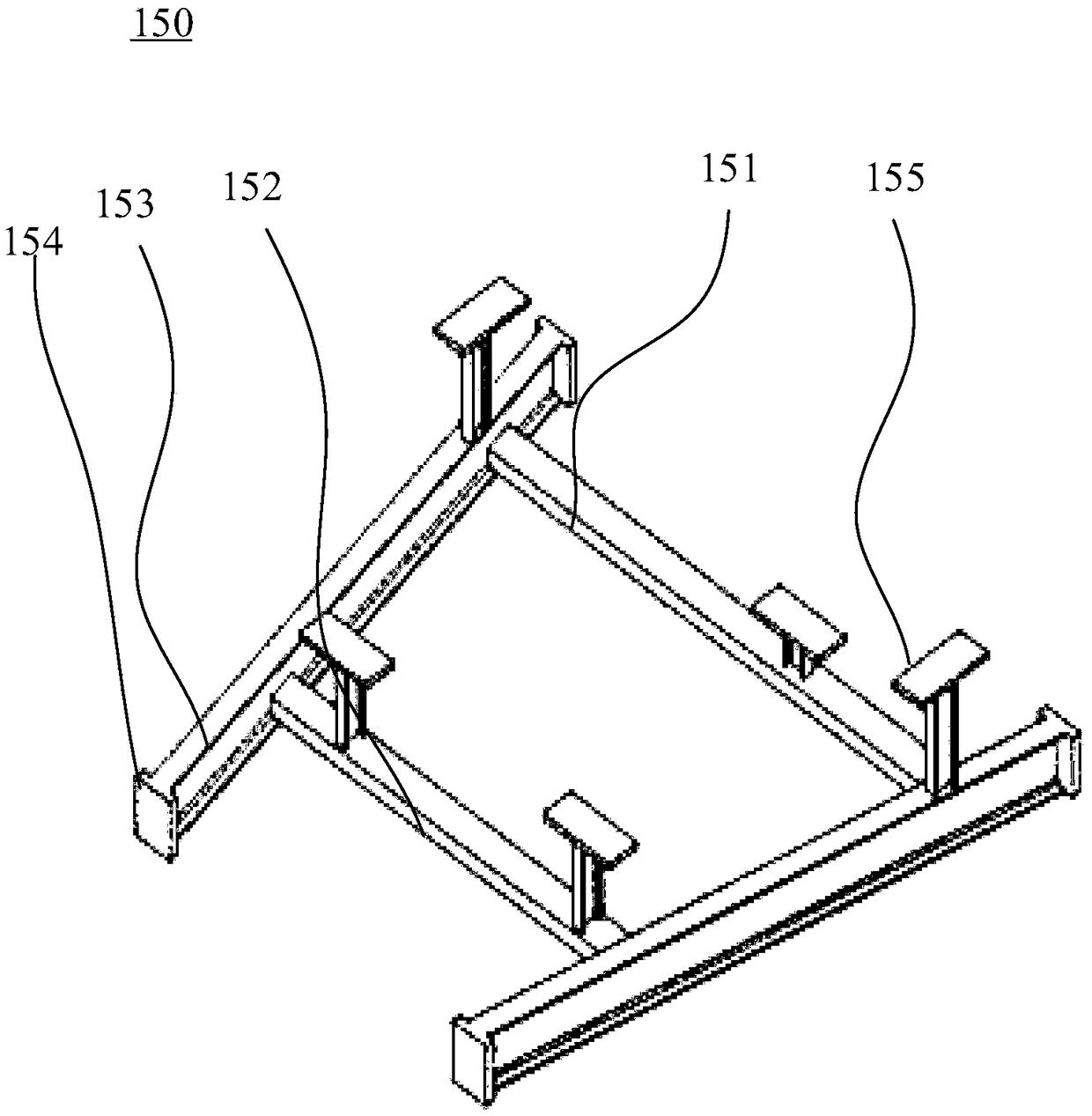

[0032] Please refer to figure 1 , the embodiment of the present invention provides a steam turbine chassis 100, including a first deck 110, a second deck 120, a third deck 130, a fourth deck 140 and a support assembly 150, the support assembly 150 includes symmetrically arranged in the center of the chassis There are two angle steels 153 on both sides of the line 101 in a figure-eight shape and a first beam 151 and a second beam 152 arranged between the two angle steels 153, the first platen 110 is detachably connected to the ends of the two angle steels 153, The second platform 120 and the third platform 130 are detachably connected with two angle steels 153 respectively; The second platform 120 and the third platform 130 are detachably connected.

[0033] It should be noted that, first, if figure 1 As shown, the two angle steels 153 arranged in a figure-eight shape have four ends in total, and the first platen 110 is connected with the two ends on the same side of the two ...

Embodiment 2

[0061] An embodiment of the present invention provides a steam turbine, including a steam turbine body and the above-mentioned steam turbine chassis 100 , and the steam turbine body is installed on the steam turbine chassis 100 .

[0062] The steam turbine provided by the embodiment of the present invention has a detachable steam turbine chassis 100, so that each part of the steam turbine chassis 100 becomes an independent device, which can be processed separately and connected by bolts for assembly and disassembly. The detachable steam turbine chassis 100 is manufactured And the flexible assembly ensures the installation accuracy, installation progress and operation quality of the complete steam turbine, which makes the complete steam turbine have the characteristics of compact structure and high working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com