A construction method of acrylic crystal resin simulated water surface

An acrylic resin, water surface construction technology, applied in the direction of coating, covering/lining, construction, etc., can solve the problem of unable to meet market demand, achieve excellent decorative effect, reduce curing time and prolong the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

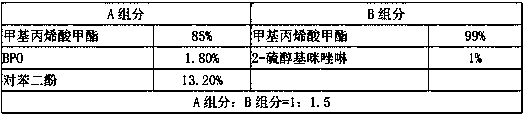

Embodiment 1

[0057] A kind of acrylic crystal resin simulation water surface construction method, its construction technological process is as follows figure 1 As shown, specifically include the following steps,

[0058] Base surface cleaning: eradicate the old coating on the surface of the construction base surface, clean up the floating dust, debris, etc., to make the construction base surface clean and tidy.

[0059] Make the cement base: spread the cement mortar on the construction base surface, scrape it flat, and maintain it until it is completely cured to form a flat cement base. By making a cement base layer on the construction base surface, the construction base surface is smoothed, the adhesion of the construction base surface is increased, and the compressive performance is improved. After the cement base is cured and cured, check whether there are cracks, hollow shells and other problems in the cement base. If there is, use a cutting machine for deep cutting and cleaning, and...

Embodiment 2

[0074] A kind of acrylic crystal resin simulation water surface construction method, it is based on embodiment 1, and the difference with embodiment 1 is:

[0075] When preparing acrylic resin, the mass ratio of component A and component B is 1:2.0; the thickness of acrylic resin poured each time is 1.8cm.

Embodiment 3

[0077] A kind of acrylic crystal resin simulation water surface construction method, it is based on embodiment 1, and the difference with embodiment 1 is:

[0078] When preparing acrylic resin, the mass ratio of component A and component B is 1:2.5; the thickness of the acrylic resin poured each time is 1.5cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com