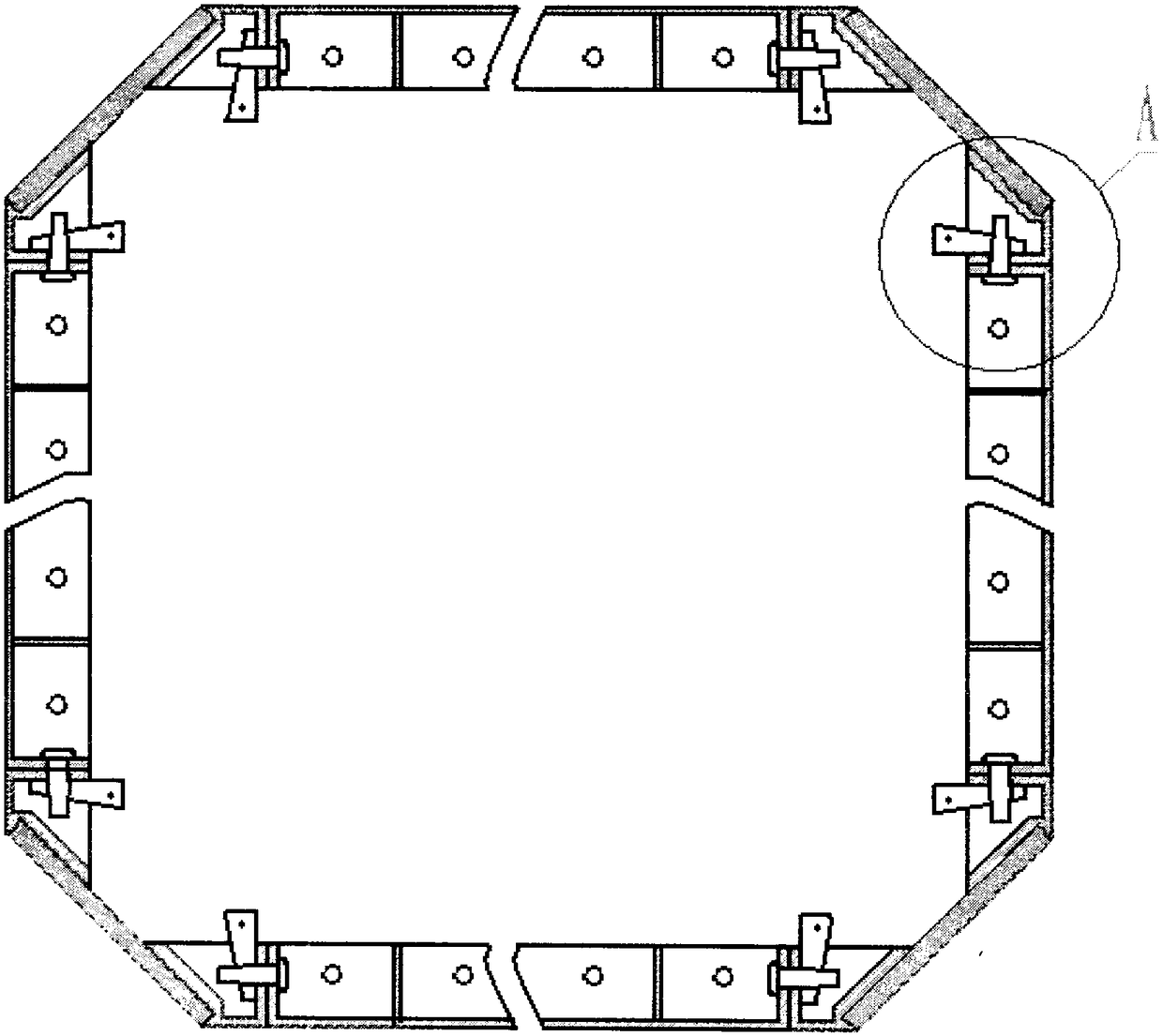

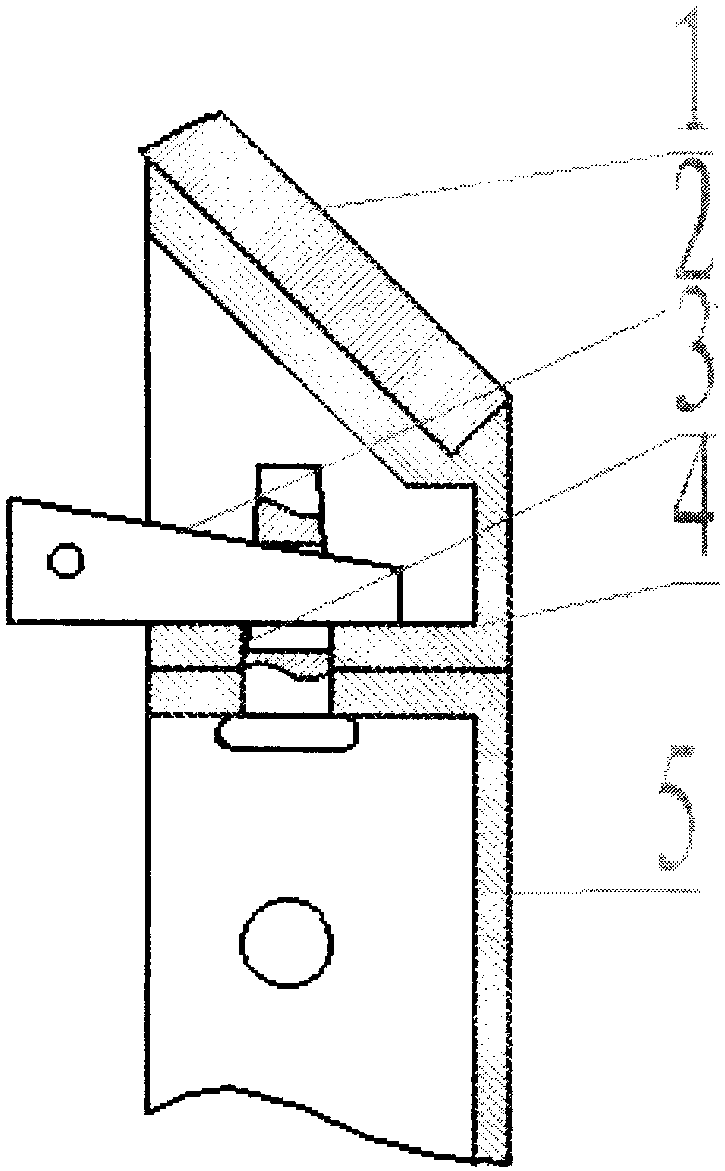

Tunnel pipe gallery inner rotating corner template

A technology of tunnel pipe and inner corner, which is applied in the connection parts of formwork/formwork/working frame, water conservancy projects, artificial islands, etc., and can solve problems such as affecting traffic and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings. Firstly, according to the design requirements of the tunnel pipe gallery, the inner corner formwork of the pipe gallery is designed and manufactured. (4) Combine with the flat formwork (1), and use screws to screw the flat formwork from the combination inner corner formwork (4), and then combine with the wall formwork (5), and the pin (3) is inserted into the through hole by the pin piece (2) Insert the flat hole on the head of the pin (3) and lock it, and the surrounding wall formwork (5) and the combined inner corner formwork (4) are combined. After the four flat formworks are combined, the inner corner formwork of the pipe gallery is formed. To be installed in the tunnel, a section of the pipe corridor channel is formed, and the cement is poured until the cement solidifies. Remove the surrounding pins (2), take out the pins (3), take away the wall formwork (5), unscrew the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com