Modulus type seamless telescopic device and a construction method thereof

A technology of seamless expansion and modulus, applied in bridge parts, bridges, buildings, etc., can solve the problems of easy aging of sealing rubber belts, insufficient bending rigidity, hidden safety hazards, etc., to improve driving comfort, easy installation and setting, The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

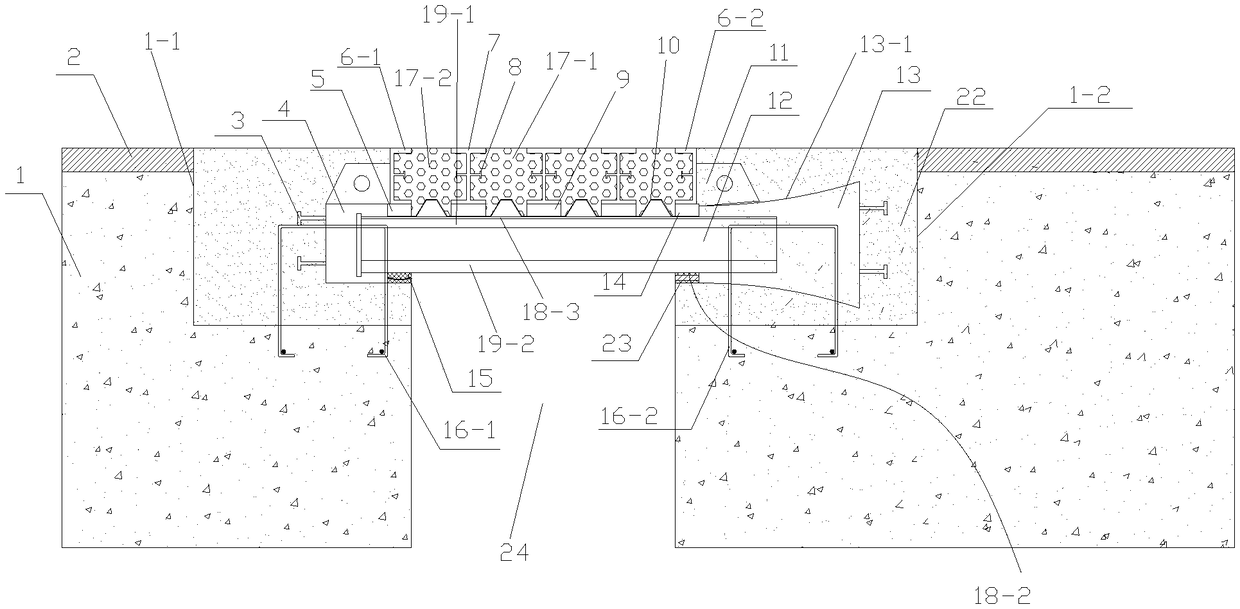

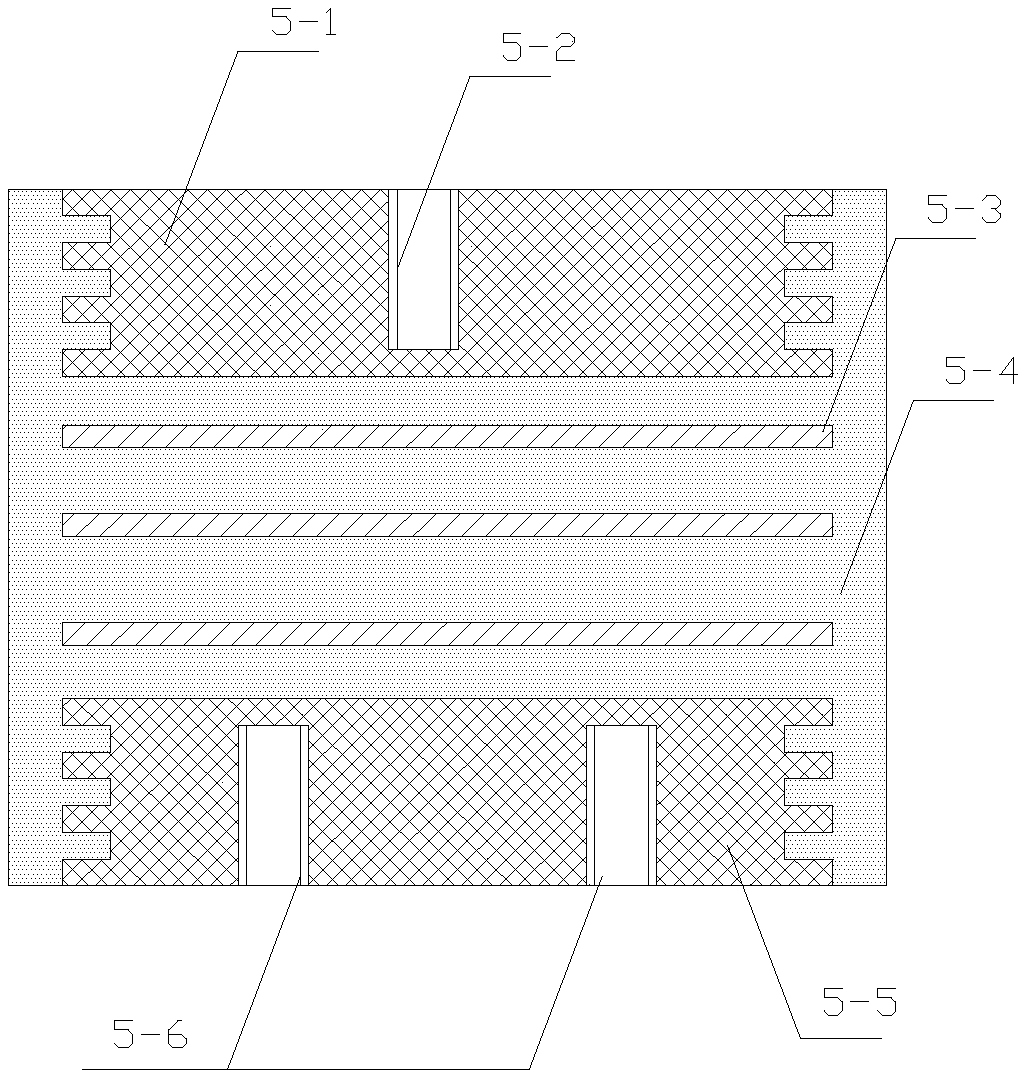

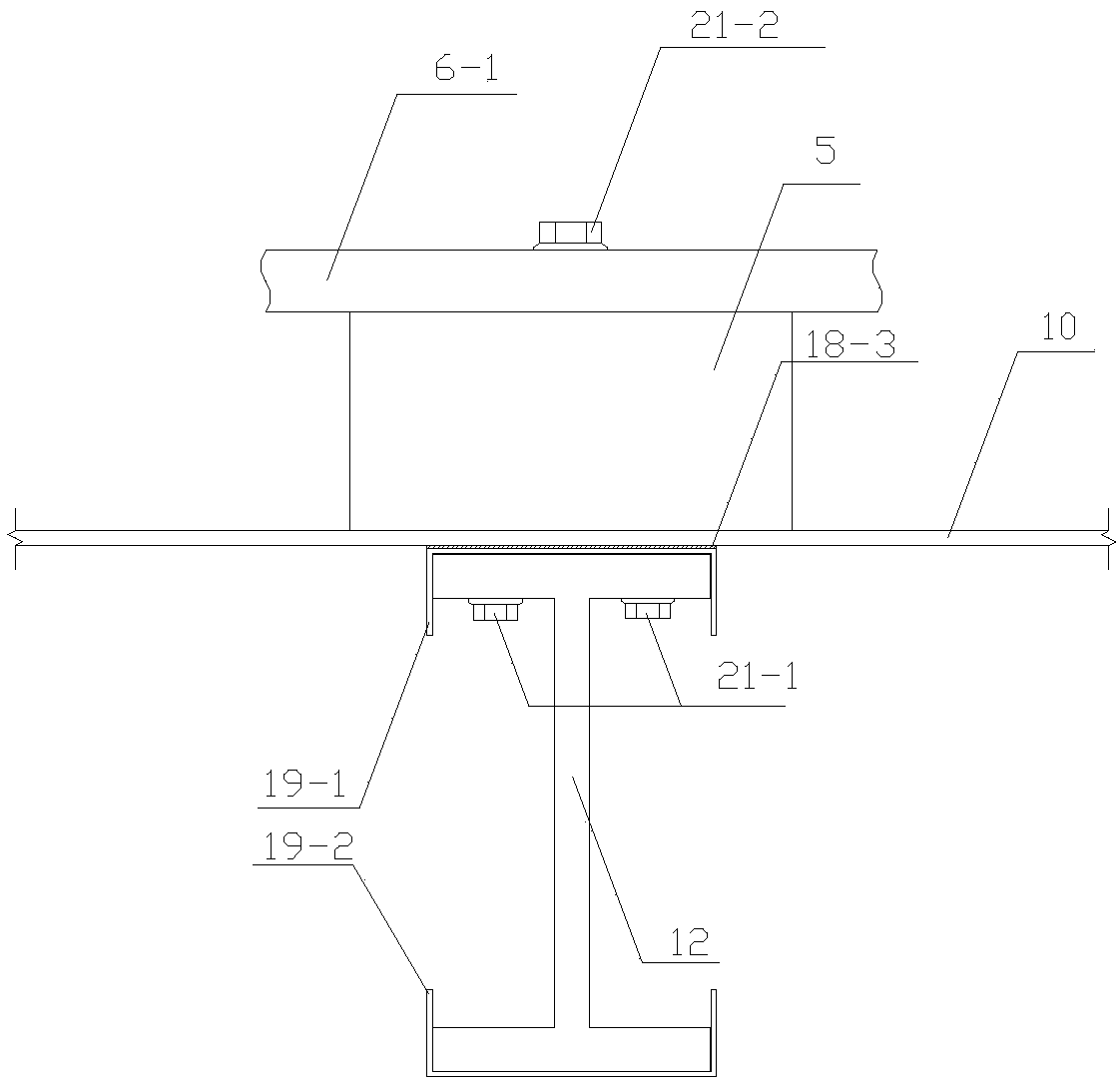

[0081] Such as figure 1 A modular seamless telescopic device shown includes a modular seamless telescopic device arranged on bridge expansion joints 24 formed by two adjacent girders or abutments 1, the modular seamless telescopic device The device includes a supporting mechanism installed in two girder bodies or abutments 1 and spanning the expansion joint 24 of the bridge, and a telescopic mechanism installed on the supporting mechanism. The telescopic mechanism includes a corrugated thin steel plate 10 and a corrugated thin steel plate 10, the telescopic deformation assembly includes two side beams symmetrically installed on both sides of the bridge expansion joint 24, a plurality of middle beams 7 arranged between the two side beams and connecting the side beams The elasto-plastic telescopic mechanism with the middle beam 7, the side beams are respectively the first side beam 6-1 and the second side beam 6-2, and the lower end of the first side beam 6-1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com