Technology for preparing metal sodium with molten electrolysis of sodium hydroxide and electrolytic system of technology

A technology of sodium hydroxide and molten electrolysis, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of inconvenient installation of purification devices, no gas protection, damage to seals, etc., to ensure integrity and safety, Effect of improving purity and preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

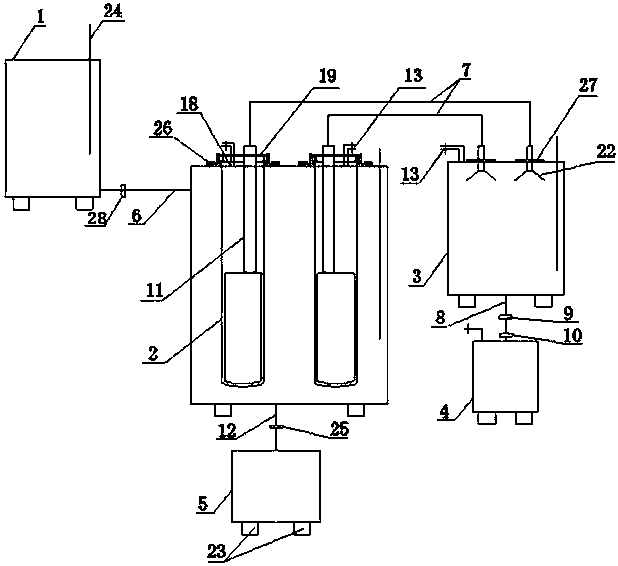

[0072] A kind of technique that prepares sodium metal by molten electrolysis of sodium hydroxide, comprises the steps:

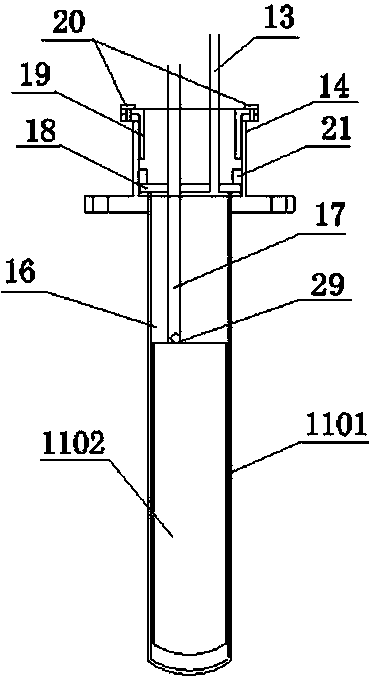

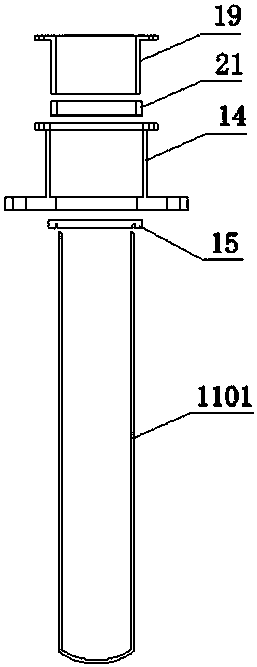

[0073] A. By opening the mechanical pump, the refined sodium temporary storage chamber 16, the refined sodium pipe 7, the refined sodium tank 3, the sodium discharge pipe 8 and the refined sodium storage tank 4 form a closed through cavity, and the through cavity is evacuated to a pressure of 10Pa, and then Introduce protective gas through the gas storage tank to a pressure of 5KPa;

[0074] B. After the operation in step A is finished, inject sodium hydroxide powder into the electrolytic cell 2, then heat the electrolytic cell 2 to 260°C at 5°C / min, keep it warm for 4h, and then inject the sodium hydroxide powder in the electrolytic cell 2 , diaphragm ceramic tube 1101 and refined sodium temporary storage chamber 16 are preheated;

[0075] C. Connect the sodium seed tank to the intake pipe 13 at the electrolysis unit 11, heat the sodium seed tank to 180...

Embodiment 2

[0087] A kind of technique that prepares sodium metal by molten electrolysis of sodium hydroxide, comprises the steps:

[0088] A. By opening the mechanical pump, the refined sodium temporary storage chamber 16, the refined sodium pipe 7, the refined sodium tank 3, the sodium discharge pipe 8 and the refined sodium storage tank 4 form a closed through cavity, and the through cavity is evacuated to a pressure of 4Pa, and then Pass the protective gas through the gas storage tank to a pressure of 0.1KPa;

[0089] B. After the operation in step A is completed, inject sodium hydroxide powder into the electrolytic cell 2, then heat the electrolytic cell 2 to 180 °C at 1 °C / min, keep it warm for 2 hours, and then inject the sodium hydroxide powder in the electrolytic cell 2 , diaphragm ceramic tube 1101 and refined sodium temporary storage chamber 16 are preheated;

[0090] C. Connect the sodium seed tank to the intake pipe 13 at the electrolysis unit 11, heat the sodium seed tan...

Embodiment 3

[0102] A kind of technique that prepares sodium metal by molten electrolysis of sodium hydroxide, comprises the steps:

[0103] A. By opening the mechanical pump, the refined sodium temporary storage chamber 16, the refined sodium pipe 7, the refined sodium tank 3, the sodium discharge pipe 8 and the refined sodium storage tank 4 form a closed through cavity, and the through cavity is evacuated to a pressure of 8Pa, and then Introduce protective gas through the gas storage tank to a pressure of 3KPa;

[0104] B. After the operation in step A is finished, inject sodium hydroxide powder into the electrolytic cell 2, then heat the electrolytic cell 2 to 120°C at 3°C / min, keep it warm for 3h, and then inject the sodium hydroxide powder in the electrolytic cell 2 , diaphragm ceramic tube 1101 and refined sodium temporary storage chamber 16 are preheated;

[0105] C. Connect the sodium seed tank to the intake pipe 13 at the electrolysis unit 11, heat the sodium seed tank to 130°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com