A parameter adjustment method to eliminate the difference in pretreatment efficiency of different lignocellulosic raw materials

A lignocellulose and parameter adjustment technology, which is applied in the field of parameter adjustment to eliminate the difference in pretreatment efficiency of different lignocellulose raw materials, can solve the problems such as time-consuming and energy-consuming, restricting industrial application, and difference in pretreatment effect, and achieves improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

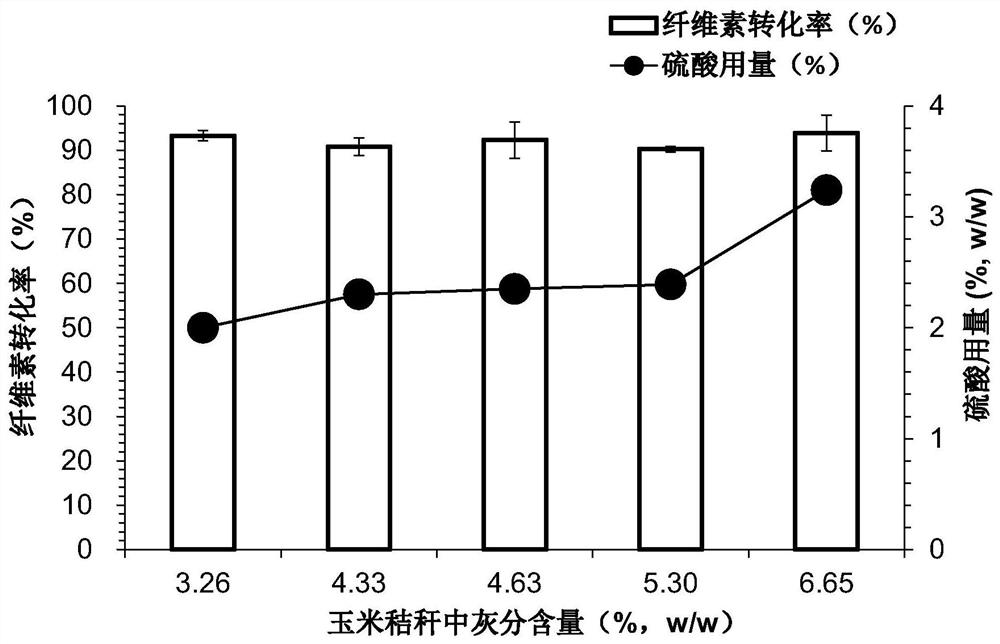

Embodiment 1

[0013] Roughly cut the air-dried corn stalks into 0.1-10cm long, and remove the large-grained stones and gravel, and directly crush them with a hammer mill until the particle size passes through a sieve with an inner diameter of 1cm, and the ash content of the raw material is 6.65%. The amount of acid is not adjusted by titration. Take 2.00% (w / w) sulfuric acid / g dry solids, use corn stalks and the acid solution formulated according to the amount of acid at a solid-liquid ratio of 2:1, at 175 ° C, 0.8 MPa Pretreatment for 5 minutes under the same conditions; the content of xylan in the pretreated material is 9.01±0.30%, the content of acetic acid is 10.56±0.24mg / g DM, and the content of furfural is 0.82±0.02mg / g DM. The batch of pretreated corn stalks was subjected to an enzymolysis test. The operating conditions were solid content of 2.5% (mass ratio), cellulase dosage of 20FPU / g dry solids, and enzymolysis time of 72 hours in a constant temperature water bath at 50°C and 150r...

Embodiment 2

[0015] Roughly cut the air-dried corn stalks into 0.1-10cm long, and remove the large-grained stones and gravel, and directly crush them with a hammer mill until the particle size passes through a sieve with an inner diameter of 1cm, and the ash content of the raw material is 6.65%. When 2g of dry solid is mixed with 100g of deionized water, the pH value at this time is 6.81. When it is titrated to pH 2.30 with 4% (w / w) sulfuric acid solution, 1.62g of acid solution is required, calculated by It is known that the amount of sulfuric acid required for the dilute acid pretreatment process is 3.24% (w / w) sulfuric acid / g dry solids, using corn stalks and the acid solution made according to the amount of acid with a solid-to-liquid ratio of 2:1, at 175 ° C , 0.8MPa under the condition of pretreatment for 5min; pretreated material xylan content 3.09±0.22%, acetic acid content 18.25±0.20mg / g DM, furfural content 3.09±0.02mg / g DM. The batch of pretreated corn stalks was subjected to an...

Embodiment 3

[0017] Roughly cut the air-dried corn stalks into 0.1-10cm long, and remove large particles of gravel, add water to clean the stalks at a mass ratio of 10:1 (water:stalks), squeeze the stalks after cleaning, and store the solids at 105°C Dry in an oven, and after drying, use a hammer mill to crush until the particle size passes through a sieve with an inner diameter of 1cm. At this time, the ash content of the raw material is 5.30%. When 2g of dry solids are mixed with 100g of deionized water, the pH value at this time It is 6.74, when using 4% (w / w) sulfuric acid solution it is titrated to pH when it is 2.30, required acid solution 1.195g, by calculating the required sulfuric acid consumption of dilute acid pretreatment process is 2.39% (w / w) Sulfuric acid / g dry solids, use corn stalks and the acid solution formulated according to the amount of acid at a solid-to-liquid ratio of 2:1, and pretreat for 5 minutes at 175°C and 0.8MPa; The sugar content is 3.18±0.03%, the acetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com