Method and device for oil production by means of mixed hydrothermal decomposition of kitchen garbage and microalgae

A kitchen waste, thermal decomposition technology, applied in the petroleum industry, fat oil/fat production, liquid carbon-containing fuel, etc., can solve the problems of incomplete conversion of biomass, low yield of liquefied oil, multi-process heat, etc., to achieve Alleviate the increasing shortage, be conducive to industrial application, and have high photosynthetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

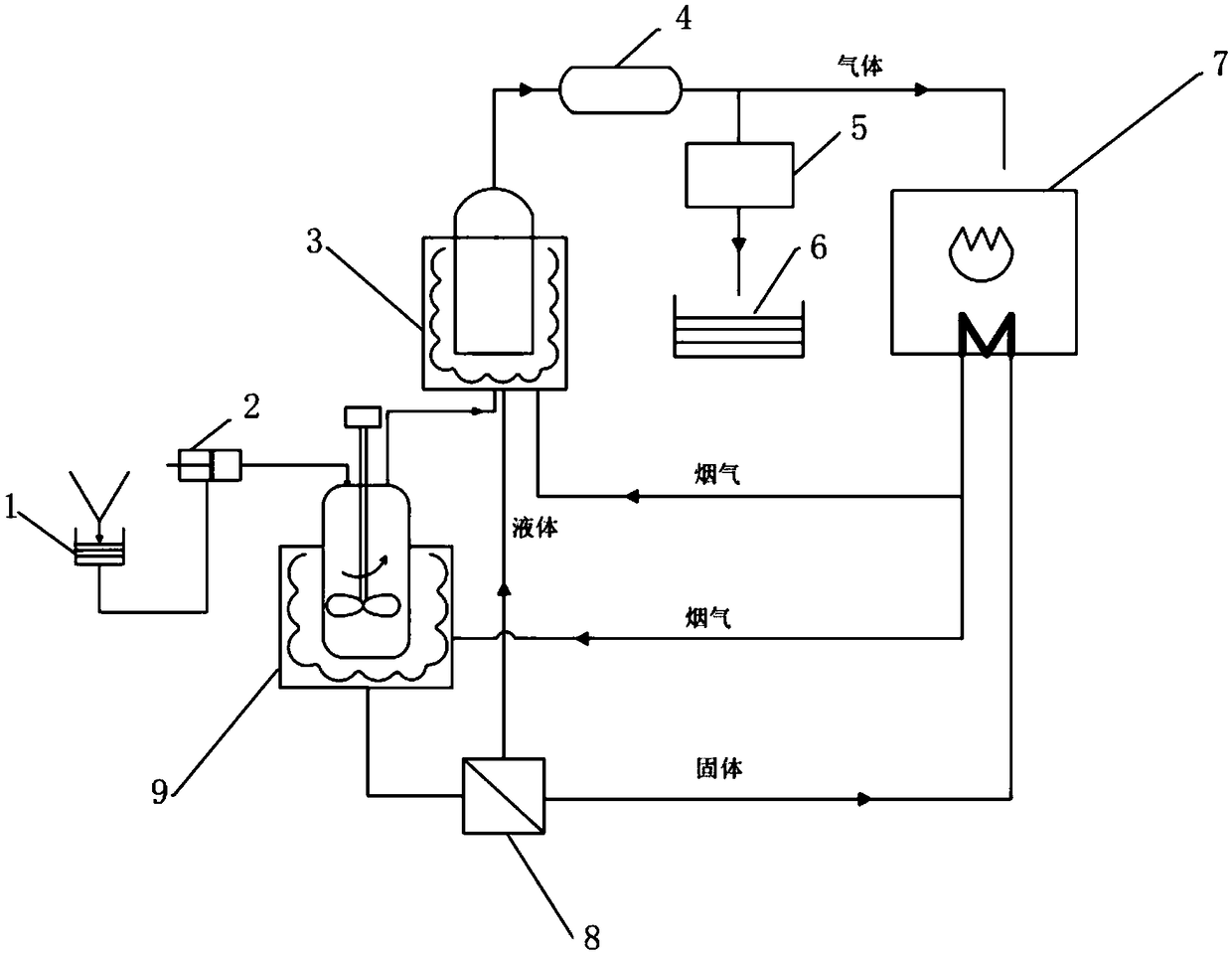

[0038] A method for producing oil by mixing kitchen waste and microalgae through hydrothermal decomposition, comprising the following steps:

[0039] (1) Pretreatment of kitchen waste and microalgae raw materials: After collecting kitchen waste, sort out the inorganic impurities in the kitchen waste, and use the residues as raw materials; centrifuge and stand still the sorted raw materials, separate After the upper layer of oil is removed, it can be used as raw material for biodiesel or industrial oil, and the residue is roughly crushed to make food waste raw material; the microalgae is crushed to make microalgae raw material; the mixture of microalgae and kitchen waste is added to water and fully mixed Form a mass fraction of 10% slurry stand-by;

[0040] (2) Seal the hydrothermal reaction device 9 of high temperature and high pressure, and fill in an inert gas to adjust the initial pressure in the reaction device;

[0041] (3) Input the mixed slurry into the hydrothermal re...

Embodiment 2

[0052] A method for producing oil by mixing kitchen waste and microalgae through hydrothermal decomposition, comprising the following steps:

[0053] (1) Pretreatment of kitchen waste and microalgae raw materials: After collecting kitchen waste, sort out the inorganic impurities in the kitchen waste, and use the residues as raw materials; centrifuge and stand still the sorted raw materials, separate After the upper layer of oil is removed, it can be used as raw material for biodiesel or industrial oil, and the residue is roughly crushed to make food waste raw material; the microalgae is crushed to make microalgae raw material; the mixture of microalgae and kitchen waste is added to water and fully mixed Forming mass fraction is that the slurry of 50% is stand-by;

[0054] (2) Seal the hydrothermal reaction device 9 of high temperature and high pressure, and fill in an inert gas to adjust the initial pressure in the reaction device;

[0055] (3) Input the mixed slurry into the...

Embodiment 3

[0066] A method for producing oil by mixing kitchen waste and microalgae through hydrothermal decomposition, comprising the following steps:

[0067] (1) Pretreatment of kitchen waste and microalgae raw materials: After collecting kitchen waste, sort out the inorganic impurities in the kitchen waste, and use the residues as raw materials; centrifuge and stand still the sorted raw materials, separate After the upper layer of oil is removed, it can be used as raw material for biodiesel or industrial oil, and the residue is roughly crushed to make food waste raw material; the microalgae is crushed to make microalgae raw material; the mixture of microalgae and kitchen waste is added to water and fully mixed Forming mass fraction is that the slurry of 60% is stand-by;

[0068] (2) Seal the hydrothermal reaction device 9 of high temperature and high pressure, and fill the initial pressure in the reducing gas to adjust the reaction device;

[0069] (3) Input the mixed slurry into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com