Hydrophobic fixation ink and preparation process thereof

A technology of hydrophobicity and ink, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems that hydrophobic agents cannot be uniformly dispersed, molecular weight increases, and does not have hydrophobic properties, so as to achieve increased bond strength, increased molecular weight, The effect of strong color fixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific preparation process of aminated hydrophobic pigment is as follows:

[0042] Step 1: Add carbon tetrachloride solution in the reaction vessel, then pass nitrogen gas for 30min;

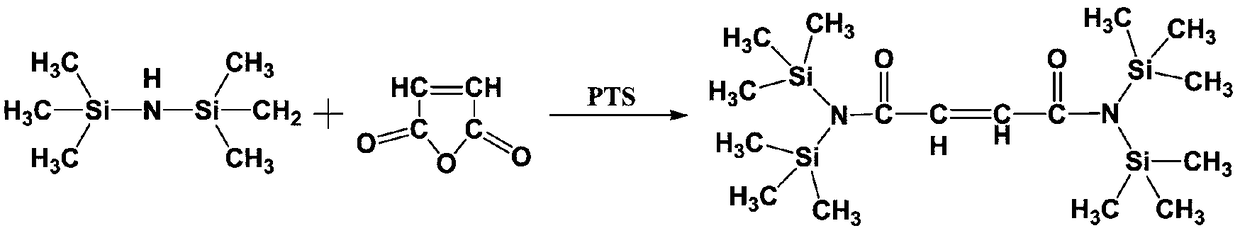

[0043] Step 2: Weigh 1 kg of hexamethyldisilazane and add it to the reaction vessel of step 1, mix well, add 2.1 kg of pigment and 0.05 kg of p-toluenesulfonic acid into it, stir and mix for 2-3 minutes, then heat up to 70°C;

[0044] Step 3: Weigh 0.38 kg of maleic anhydride and dissolve it in acetone to prepare a maleic anhydride solution, then add the prepared solution dropwise to step 2, vacuumize while adding, and stir at constant temperature for 3 hours after the addition is complete. Then filter and wash to obtain a hydrophobic pigment; 0.38-0.41 g of maleic anhydride, 2.1-2.2 g of pigment, and 0.05 g of p-toluenesulfonic acid are added to each gram of hexamethyldisilazane;

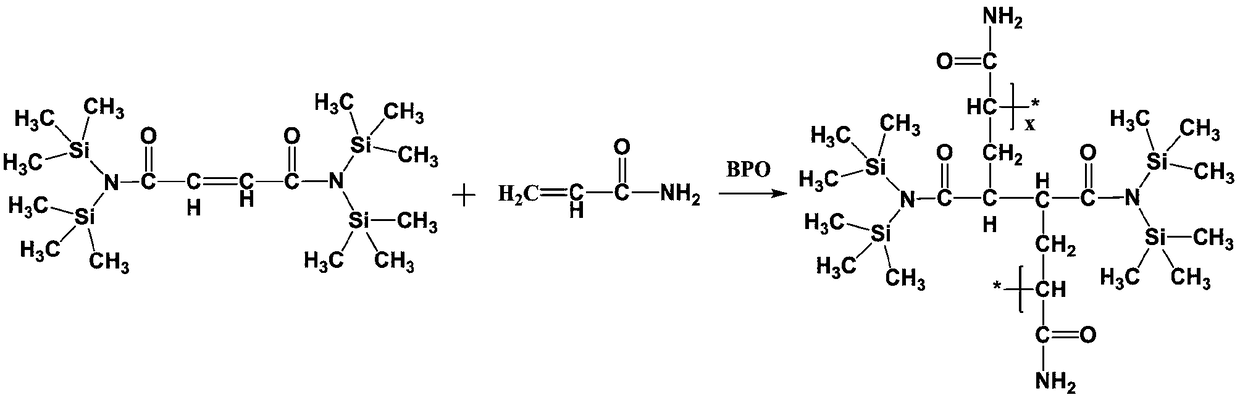

[0045] Step 4: Add 2kg of the hydrophobic pigment prepared in step 3 into water, and at the same tim...

Embodiment 2

[0047] The specific preparation process of aminated hydrophobic pigment is as follows:

[0048] Step 1: Add carbon tetrachloride solution in the reaction vessel, then pass nitrogen gas for 30min;

[0049] Step 2: Weigh 1 kg of hexamethyldisilazane and add it to the reaction vessel of step 1, mix well, add 2.2 kg of pigment and 0.05 kg of p-toluenesulfonic acid into it, stir and mix for 2-3 minutes, then heat up to 70°C;

[0050] Step 3: Weigh 0.38 kg of maleic anhydride and dissolve it in acetone to prepare a maleic anhydride solution, then add the prepared solution dropwise to step 2, vacuumize while adding, and stir at constant temperature for 3 hours after the addition is complete. Then filter and wash to obtain the hydrophobic pigment;

[0051] Step 4: Add 2kg of the hydrophobic pigment prepared in step 3 into water, and at the same time add 2.6kg of benzoyl peroxide to it, mix well and heat up to 110°C, then add 1.8kg of acrylamide to it, and stir for 5 hours to obtain a...

Embodiment 3

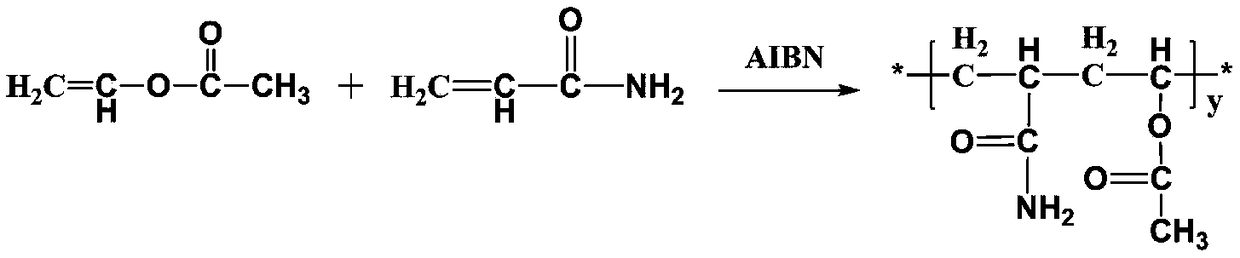

[0053] The specific preparation process of the modified binder is as follows:

[0054] ① Weigh 710g of acrylamide and dissolve it in 1.2L of ethanol solution to obtain an acrylamide solution;

[0055] ②Add 860g of vinyl acetate and 1.3kg of azobisisobutyronitrile into 3L of ethanol solution, raise the temperature to 75°C, then add acrylamide solution drop by drop, react for 3 hours after the addition is complete, and obtain modified polyvinyl alcohol ester .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com