Preparation process of a high-performance piezoelectric ceramic

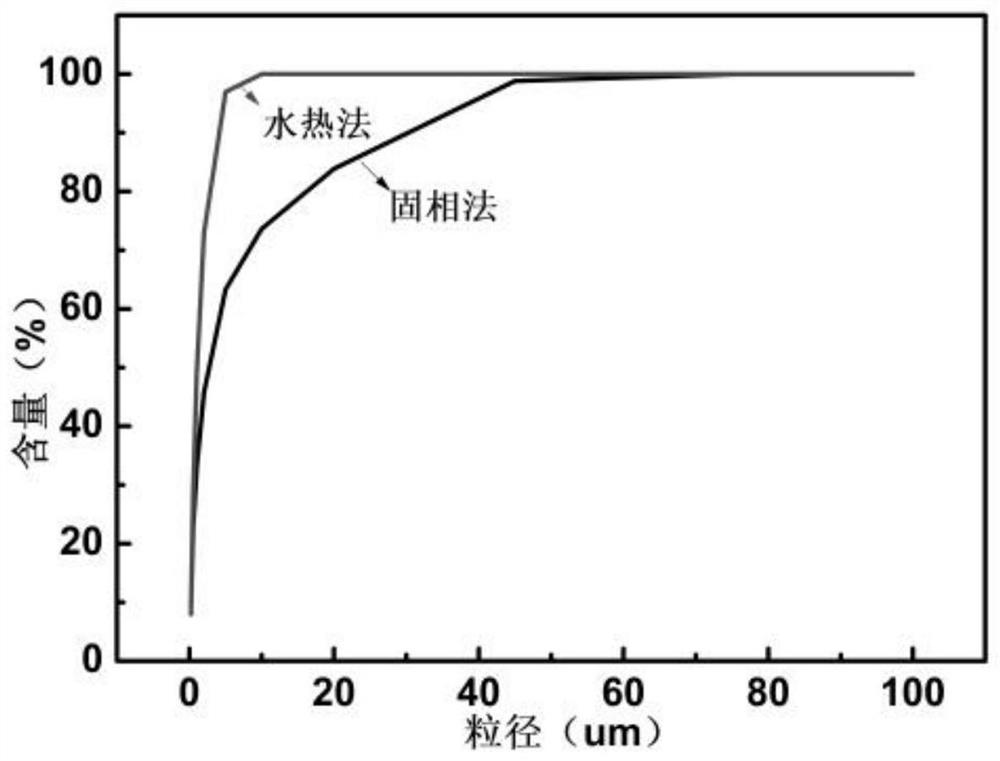

A technology for piezoelectric ceramics and preparation process, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of difficult process stability, increased ceramic raw material cost, complex reaction system, etc. , to achieve the effect of narrow particle size distribution, reduced raw material cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0034] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0035] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 70°C to dry to obtain a powder;

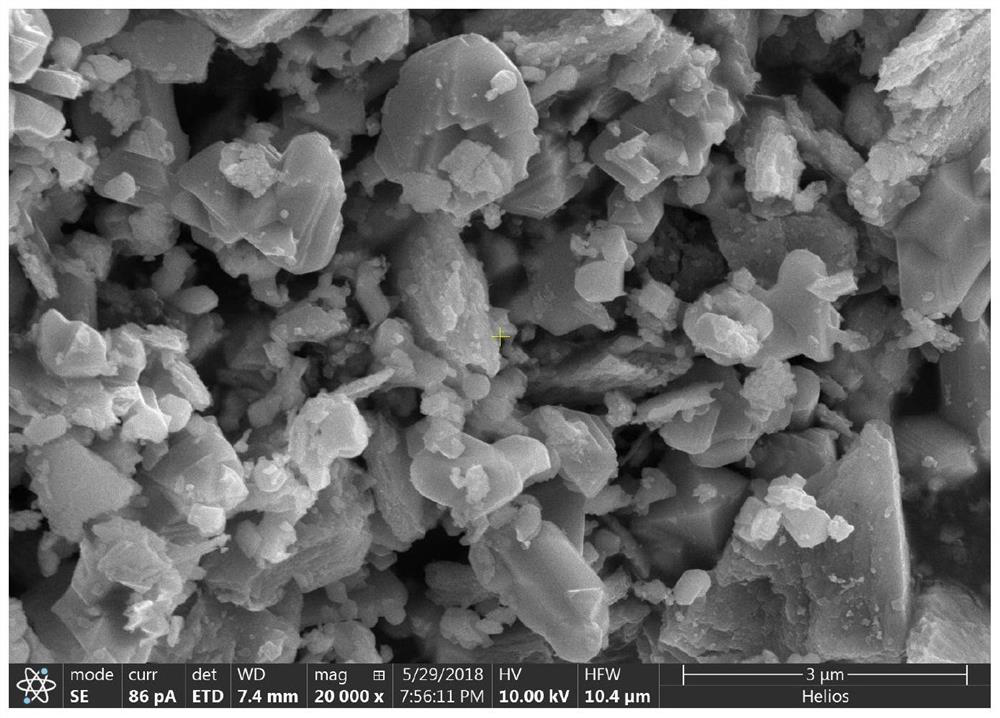

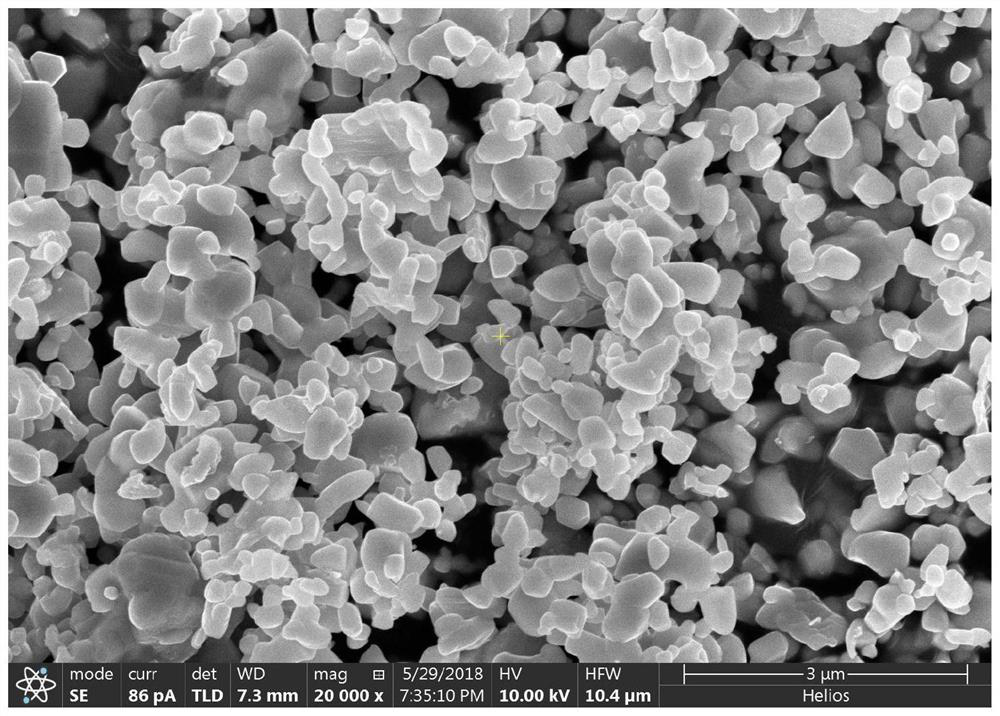

[0036] 3) Add water to the powder, then add ammonia water, and then heat for hydrothermal treatment. In the reaction system of hydrothermal treatment, the concentration of ammonia water is 1mol / L, the treatment temperature of hydrothermal treatment is 300°C, and the treatment time of hydrothermal treatment is 15h. The powder after hydrothermal treatment is dried in a drying oven at 70°C to obtain piezoelectric ceramic raw material powder;

[0037] 4) Add 300 g of deionized...

Embodiment 2

[0038] Embodiment 2: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0039] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0040] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 60° C. to dry to obtain a powder;

[0041] 3) Add water to the powder, then add citric acid, then heat for hydrothermal treatment, the concentration of citric acid in the reaction system of hydrothermal treatment is 0.5mol / L, the treatment temperature of hydrothermal treatment is 200°C, and the treatment time of hydrothermal treatment is After 25 hours, the hydrothermally treated powder was dried in a drying oven at 60°C to obtain piezoelectric ceramic raw material powder;

[0042] 4) Add 250 g of deionize...

Embodiment 3

[0043]Embodiment 3: A preparation process of high-performance piezoelectric ceramics, the steps are as follows:

[0044] 1) by mass percentage, get Pb 3 o 4 65%, TiO 2 10%, ZrO 2 5%, Nb 2 o 5 15% and NiO 5% are mixed to obtain piezoelectric ceramic raw materials;

[0045] 2) Put the piezoelectric ceramic raw materials into a ball mill tank, add alcohol, fully mix the raw materials for ball milling, and place the slurry obtained after ball milling in a drying oven at 120° C. to dry to obtain a powder;

[0046] 3) Add water to the powder, then add oxalic acid, and then heat for hydrothermal treatment. In the reaction system of hydrothermal treatment, the concentration of oxalic acid is 2mol / L, the treatment temperature of hydrothermal treatment is 400°C, and the treatment time of hydrothermal treatment is 5h. The powder after hydrothermal treatment is dried in a drying oven at 80°C to obtain piezoelectric ceramic raw material powder;

[0047] 4) Add 350 g of deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com