Design method of cement stabilized iron tailing sand base course material

A technology for stabilizing iron tailings and cement, which is applied in the field of road engineering materials, can solve problems such as the inability to meet the design of cement-stabilized iron tailings sand base materials, and achieve great social significance, huge economic benefits, and the effect of improving the status quo of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Embodiment one: a kind of cement-stabilized iron tailings sand base material design method comprises the following steps:

[0025] Step 1: Determine the scope of use of the design parameters, the design parameters being iron tailings fineness modulus X 1 , iron tailings sand consumption X 2 And the amount of cement binder X 3 ;

[0026] Step 2: According to the scope of use of the design parameters determined in step 1, use the star-point design method to design the test, and measure the 7-day unconfined compressive strength R of each group of tests in the star-point design test table;

[0027] Step 3: According to the 7-day unconfined compressive strength R of each group of tests in the star point design test table measured in step 2, perform multiple nonlinear regression analysis to obtain a ternary quadratic fitting equation;

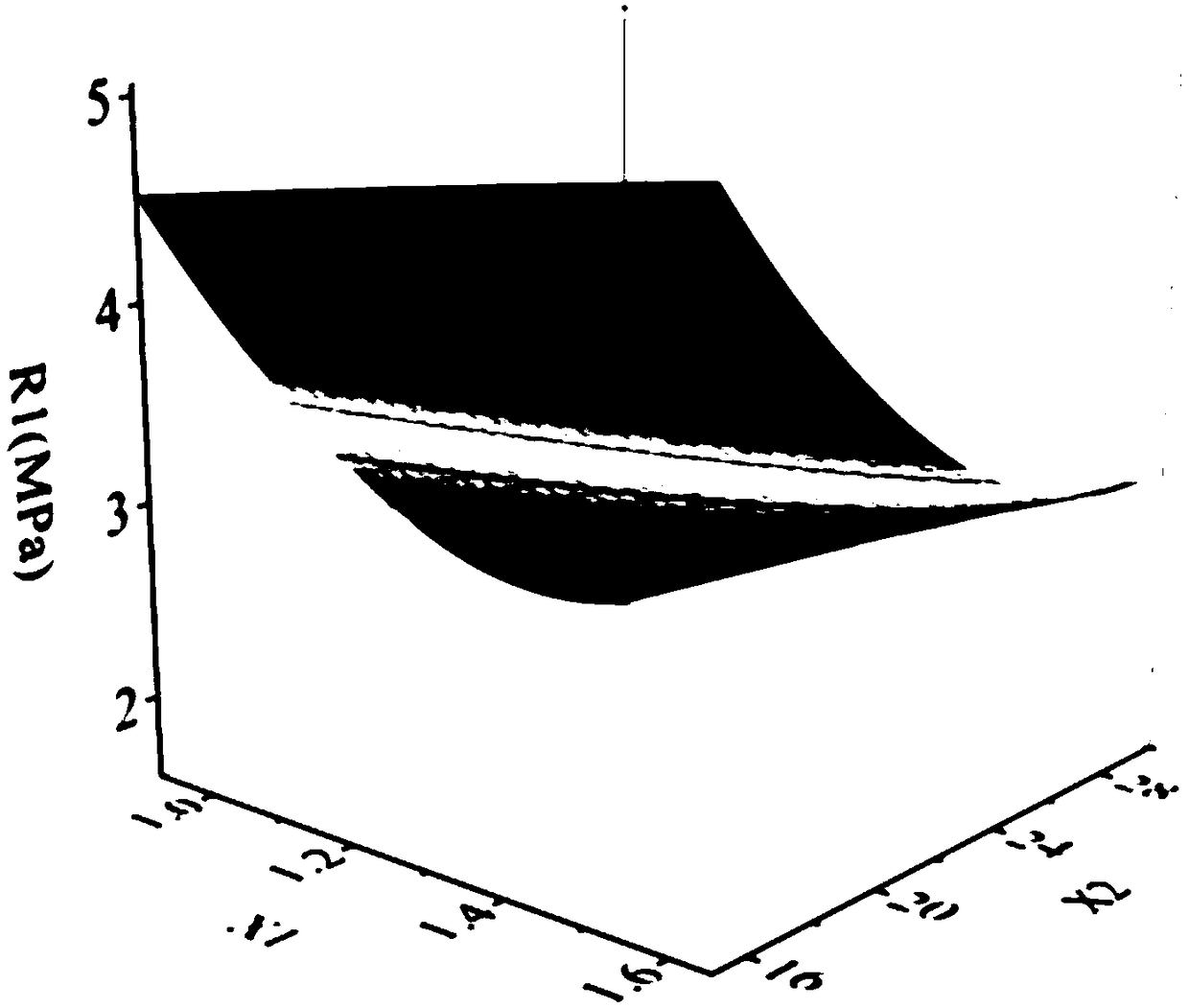

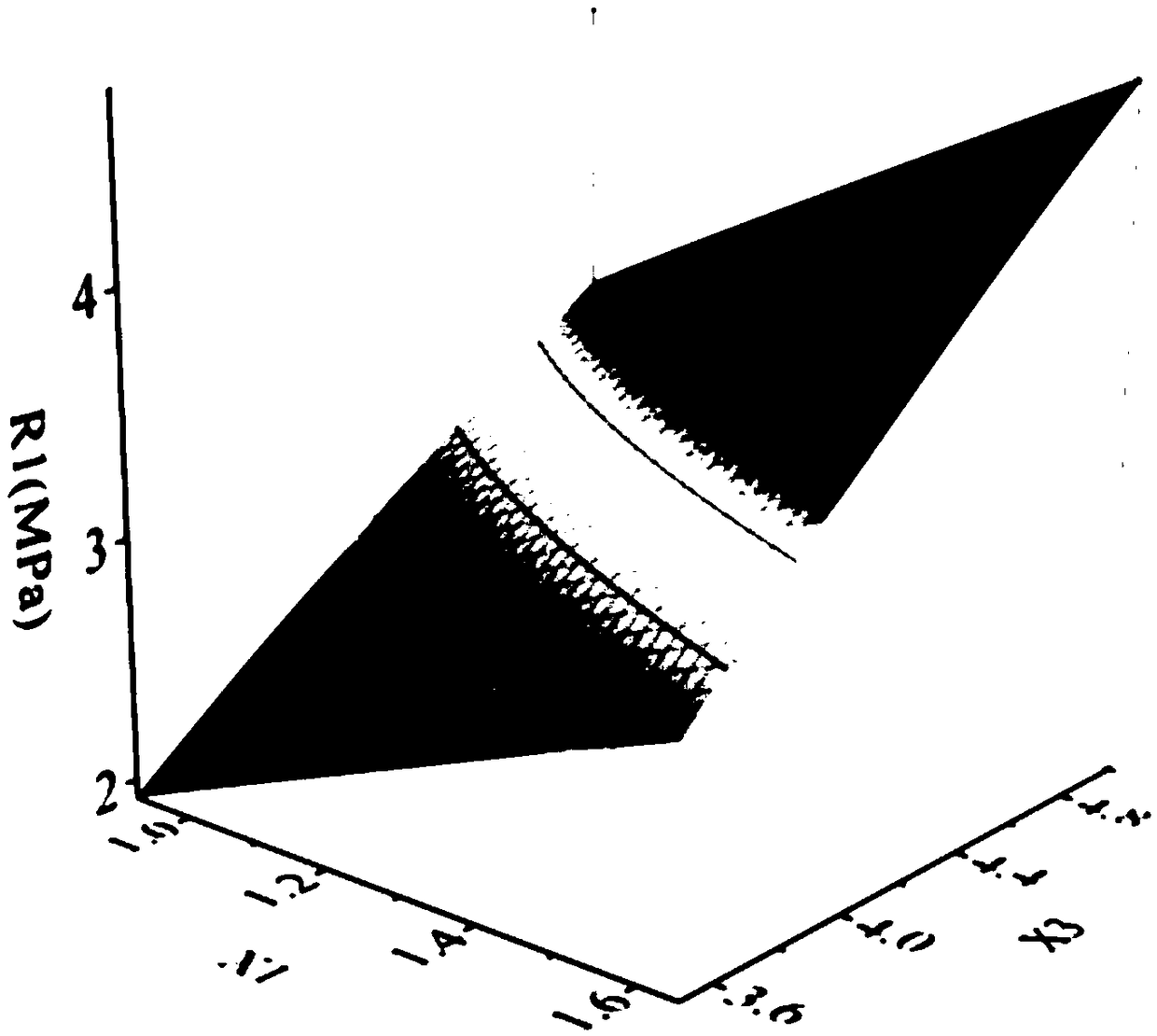

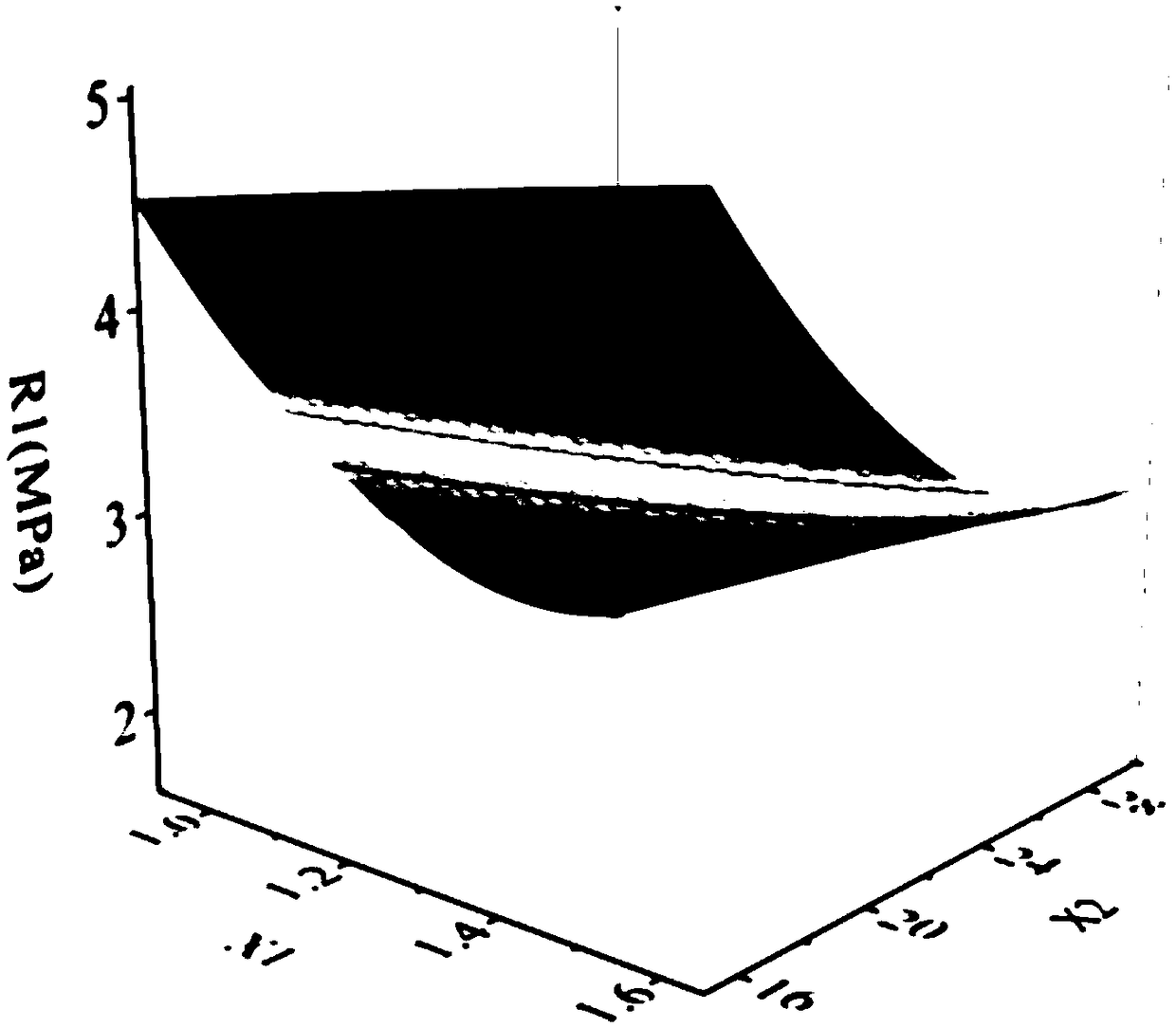

[0028] Step 4: Use the ternary quadratic fitting equation obtained in Step 3 as a prediction model to obtain the effect surface diagram, o...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the scope of use of the design parameters determined in the step one is specifically:

[0037] Select the fineness modulus of iron tailings sand, the amount of iron tailings sand and the amount of cement binder as the three key investigation factors in the design of the base, and determine the reasonable range of values for the above three factors according to the pre-test and the characteristics of the material itself. Set the fineness modulus of iron tailings sand as 0.7 to 1.9, and set the fineness modulus of iron tailings sand as X 1 , The amount of iron tailings used in the base layer is set at 5% to 30%, and the amount of iron tailings is set to X 2 , The amount of cement binder is set at 2% to 8%, and the amount of cement binder is set to X 3 .

[0038] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in the described step two, according to the range of use of the design parameters determined in step one, adopt the star point design method to design the test, measure the star point design test table The specific process of the 7-day unconfined compressive strength R of each group of tests is:

[0040] For iron tailings sand fineness modulus X 1 , iron tailings sand consumption X 2 , the amount of cement binder X 3 Three influencing factors are used to transform the value of the code factor of the star point design, and the value of the influencing factor is converted in proportion to the difference of the code. Here is the three-factor star point design. The value point α is 1.732(3 1 / 2 ), the specific results are shown in Table 1;

[0041] Table 1 Factor code levels and values

[0042]

[0043] According to the values of the three factors, design the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com