Environment-friendly automatic carton manufacturing machine

An automatic and environmentally friendly technology, applied in the field of carton manufacturing devices, can solve the problems that the equipment is only suitable for large-scale enterprise production, it is difficult to use cartons for secondary processing, and there is not enough integrated equipment to achieve shortened production hours and complete functions , shear mechanism and binding mechanism optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

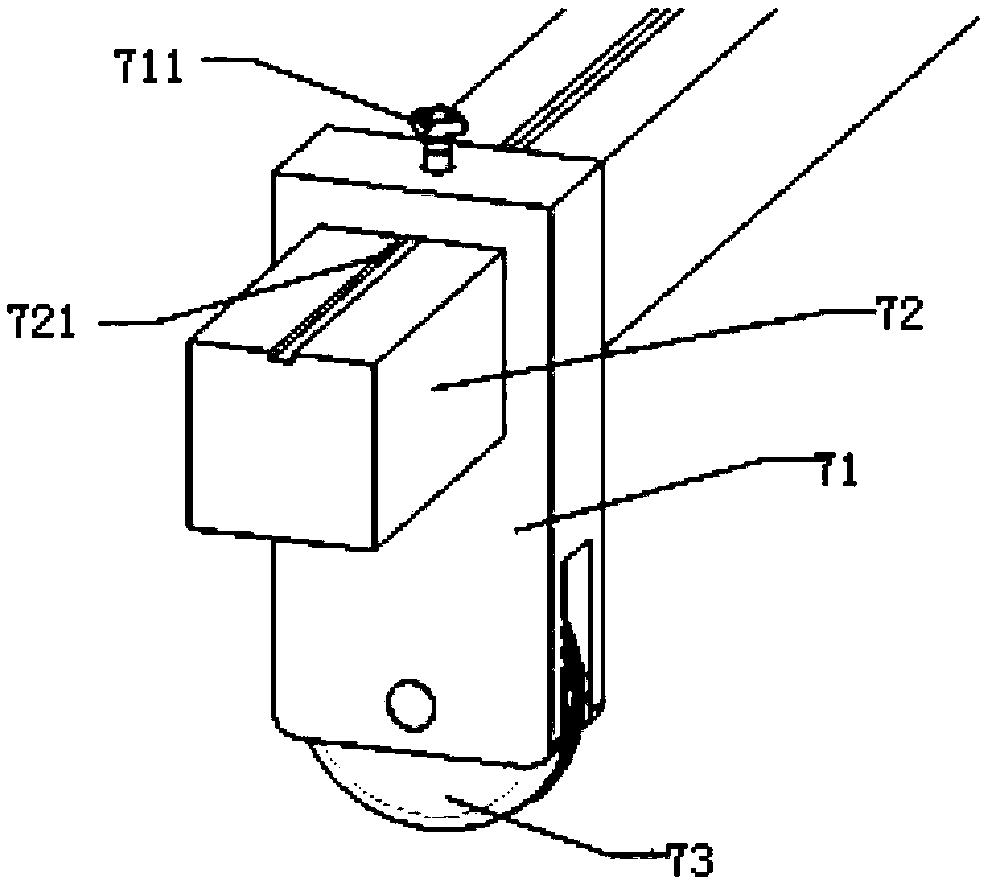

[0058] The working principle of this environment-friendly automatic box making machine is to adjust the position of each pressing wheel and cutting wheel 92 between operations, and at the same time adjust the distance between the screw rod 121 and the push plate 122 to ensure the horizontal accuracy of the cardboard 15, and then Place the corrugated cardboard 15 of the corresponding specification produced by the paper mill on the conveyor belt 5 of the machine, start the motor I1, the motor I1 drives the reducer 3 and the pulley I2 to rotate, drives the conveyor belt 5 to move, and conveys it to the longitudinal indentation through the conveyor belt 5 At device 7, during the movement of the conveyor belt 5, the cardboard 15 is under the longitudinal creasing support, and the process of longitudinal creasing is completed through the interaction between the pressure wheel protrusion 16 and the support plate groove 1421; Finally, the cardboard 15 will be transported to the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com