Treatment method of MDF board for furniture processing

A processing method and furniture technology, applied in the direction of surface pretreatment, wood processing equipment, processing machines for manufacturing flat surfaces, etc., can solve product quality problems, boards are prone to cracking, etc., to reduce man-hours, improve waterproof and durability High temperature performance, increase the effect of wrapping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In an embodiment of the present invention, a method for processing an MDF board for furniture processing comprises the following steps:

[0019] S1, MDF board pretreatment: Plan and mill the four sides of the MDF board after blanking, and then chamfer the outer corners of the MDF board, and then use a special-shaped sander to remove the outer knife marks of the MDF board to improve the MDF board. Surface accuracy, which facilitates better lamination of cold-coated plain white paper;

[0020] S2, Wrapping paper: Paste the cold-coated plain white paper on the outer surface of the MDF board using the scraping process. Note that here, the end of the cold-coated plain white paper needs to extend to the inside of the MDF board, so as to protect the MDF board. The outer surface of the body is fully covered, and then the health-preserving treatment is carried out, and the health-preserving time shall not be less than 72 hours;

[0021] S3, powder spraying: Put the result of st...

Embodiment 2

[0023] Embodiment 1 is a processing method for a single MDF board. In actual application, the board may be formed by splicing and fixing multiple MDF boards. Therefore, special processing is required for the splicing and fixing of multiple MDF boards. Specifically, Include the following steps:

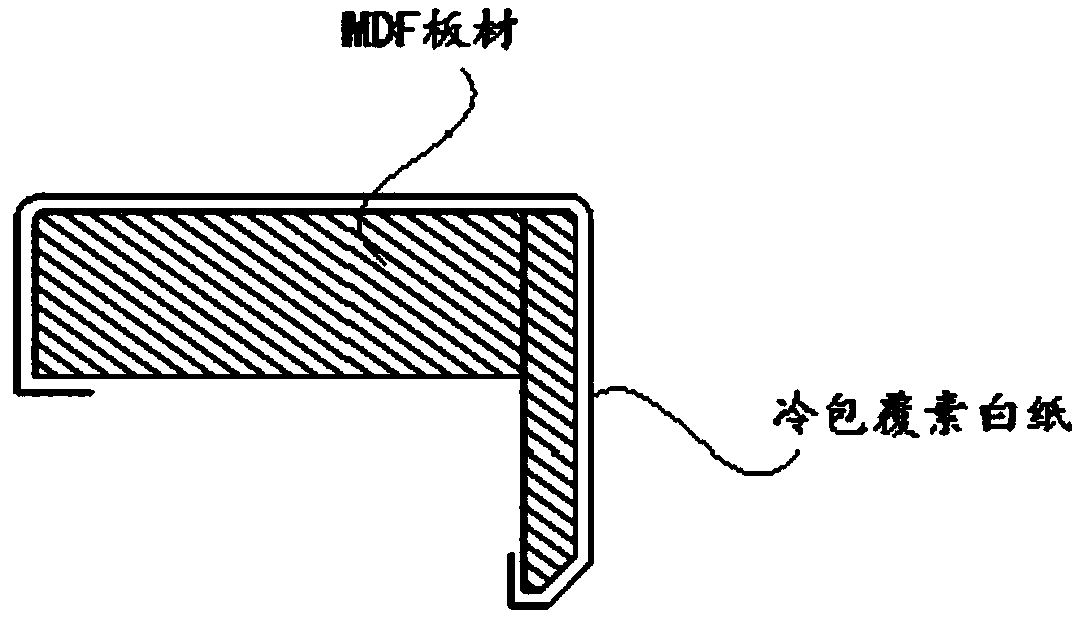

[0024] S1, MDF board pretreatment: V-shaped grooves and V-shaped blocks are processed on the MDF board, and multiple MDF boards are connected and formed by V-shaped grooves and white latex, and then planed and milled on four sides, and then the outer corners of the overall MDF board are After chamfering, use a special-shaped sander to remove the outer knife marks on the MDF board to improve the surface accuracy of the MDF board and facilitate the better lamination of the cold-coated plain white paper. After the lamination is completed, as figure 1 shown;

[0025] S2, Wrapping paper: Paste the cold-coated plain white paper on the outer surface of the MDF board using the scraping proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com