A kind of forging device for aluminum forgings for automobile production

A technology for forgings and automobiles, which is applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc. It can solve the problems of high cost, affecting forging efficiency, and large limited range, so as to reduce the loss of raw materials The effect of improving the efficiency of forging production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

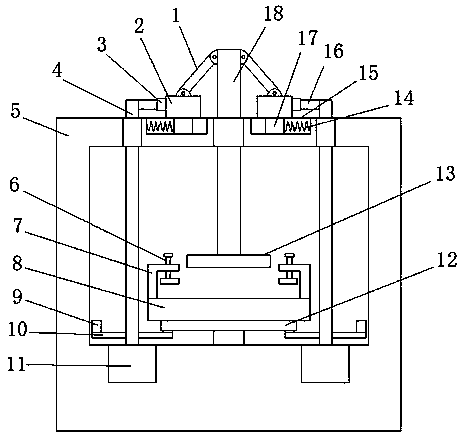

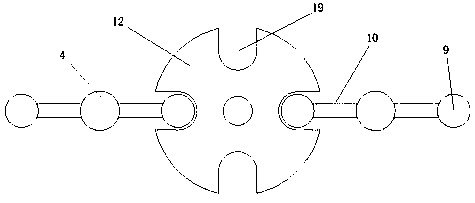

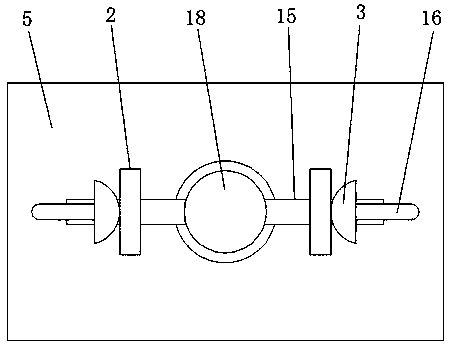

[0021] Embodiment: When in use, the aluminum plate raw material during automobile production is placed on the top of the placement plate 8, and the threaded rod 6 is turned to make the threaded rod 6 descend, and the threaded rod 6 drives the splint to descend, and the aluminum plate raw material is clamped, and then started Rotating motor 11, rotating motor 11 drives rotating rod 4 to rotate, and rotating rod 4 drives push rod 16 and push plate 3 to rotate, because push plate 3 is arranged in arc structure, so push plate 3 can push movable block 2 to move, and movable block 2 Drive slide block 17 to slide in chute 15, and slide block 17 squeezes spring 14, while movable block 2 moves, can drive articulated rod 1 to move, articulated rod 1 drives movable rod 18 to rise, when rotating rod 4 continues to rotate to When the push plate 3 was separated from the movable block 2, the restoring force of the spring 14 and the gravity of the pressing plate 13, the movable rod 18, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com