Extrusion preparation method of titanium alloy thin-walled profile

A titanium alloy and profile technology, which is applied in the field of preparation of titanium alloy profiles, can solve problems such as long production cycle, high personnel cost, and large mold consumption, and achieve the effects of reduced equipment operating costs, high dimensional accuracy, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

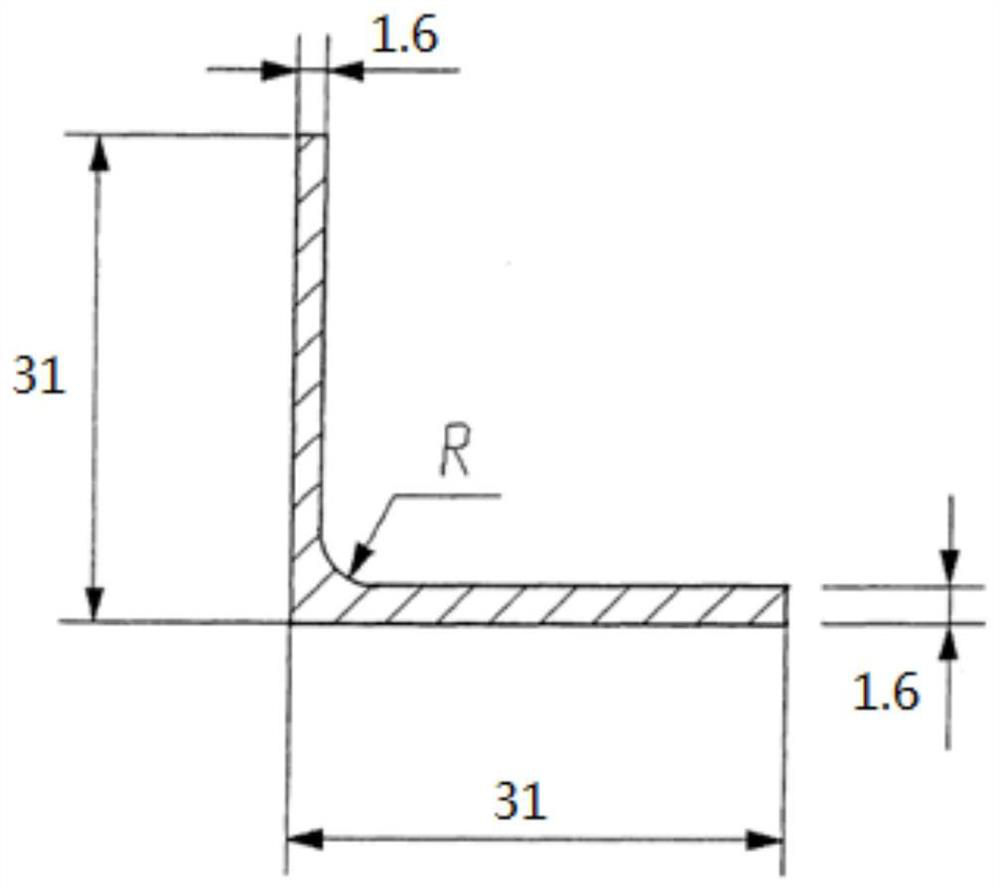

[0026] see figure 1 , embodiment one is to adopt the extrusion die of L-shaped die hole to prepare L-shaped profile, and the wall thickness of L-shaped profile is 1.6mm, and its specific preparation method comprises the steps:

[0027] Step 1, using a vacuum consumable electric arc furnace to smelt a TC4 titanium alloy Φ710mm ingot, and smelt it twice. The ingot is planed and milled, and the phase transition point of the test is 990-1000°C;

[0028] Step 2: Coat the ingot in step 1 with an anti-oxidation protective coating, heat it in a natural gas furnace, and forge it into a Φ220×L mm billet on a 2,500-ton fast forging machine, and forge it at 1,200°C for 2 to 3 times , (α+β) two-phase zone forging 1 to 2 fire times, to ensure that the total deformation is greater than 50%;

[0029] Step 3, machining the rod blank of step 2 to obtain a smooth rod blank of Ф216×350 mm;

[0030] Step 4, using alcohol to clean the polished billet prepared in step 3, placing it in a resistanc...

Embodiment 2

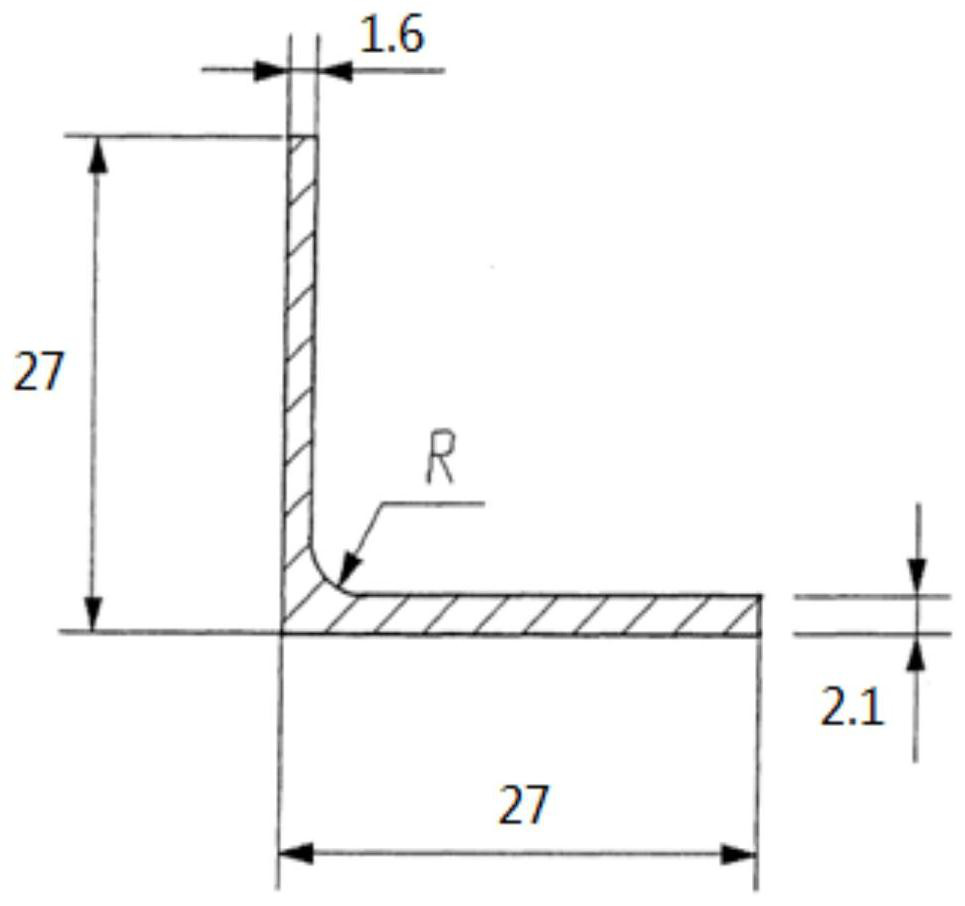

[0042] see figure 2 , embodiment two is to adopt the extrusion die of L-shaped die hole to prepare L-shaped profile, and one side wall thickness of L-shaped profile is 1.6mm, and the other side wall thickness is 2.1mm, and its specific preparation method comprises the following steps:

[0043] Step 1: Use a vacuum consumable electric arc furnace to smelt TC4 titanium alloy Φ710mm ingots, and melt them twice; plan and mill the ingots, and test that the phase transition point is 970-980°C;

[0044] Step 2: Coat the ingot in step 1 with an anti-oxidation protective coating, heat it in a natural gas furnace, and forge it into a Φ220×L mm billet on a 2,500-ton fast forging machine, forging at 1180°C for 2 to 3 times , (α+β) two-phase zone forging 1 to 2 fire times, to ensure that the total deformation is greater than 50%;

[0045] Step 3, machining the rod blank of step 2 to obtain a smooth rod blank of Ф216×350 mm;

[0046] Step 4, using alcohol to clean the polished billet pre...

Embodiment 3

[0055] Embodiment three is to adopt the extrusion die of T-shaped die hole to prepare T-shaped profile, and its concrete preparation method comprises the steps:

[0056] Step 1, using a vacuum consumable electric arc furnace to smelt a TC4 titanium alloy Φ710mm ingot, and smelt it twice. The ingot is planed and milled, and the phase transition point of the test is 990-1000°C;

[0057]Step 2: Coat the ingot in step 1 with an anti-oxidation protective coating, heat it in a natural gas furnace, and forge it into a Φ220×L mm billet on a 2,500-ton fast forging machine, and forge it at 1,200°C for 2 to 3 times , (α+β) two-phase zone forging 1 to 2 fire times, to ensure that the total deformation is greater than 50%;

[0058] Step 3, machining the rod blank of step 2 to obtain a smooth rod blank of Ф216×350 mm;

[0059] Step 4, using alcohol to clean the polished billet prepared in step 3, placing it in a resistance furnace, drying it at 250°C for 15 minutes, taking it out and perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com