Robot system with casting surface autonomous detection and degraded product sorting function

A robot system and mobile robot technology, applied in the field of casting autonomous inspection and defective product sorting, can solve the problems affecting inspection efficiency and accuracy, manpower and economic losses, and large inspection workload, and achieve small workload and labor efficiency. High and Compatible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

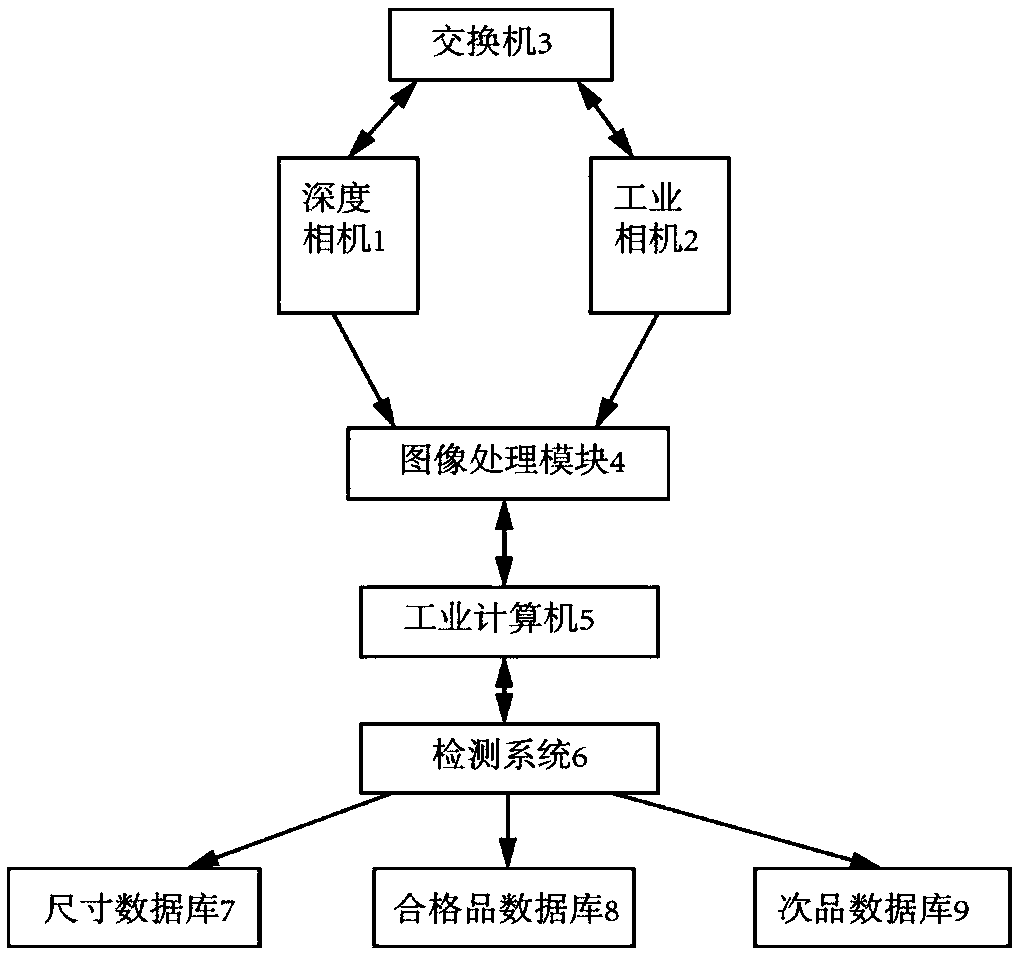

[0016] Such as figure 1 As shown, the industrial camera 1 and the depth camera 2 are connected to each other through the switch 3, the data collected by the industrial camera 1 and the depth camera 2 are fed back to the image processing module 4, and the image processing module 4 and the detection system 6 are integrated in the industrial computer 5 , after the collected data is processed by the image processing module 4, the detection system 6 adopts the advanced detection algorithm based on the deep convolutional neural network to perform surface defect detection and size recognition calculation, and the obtained workpiece size data is included in the size database 7, and the defect The test results are classified into qualified product database 8 and defective product database 9 .

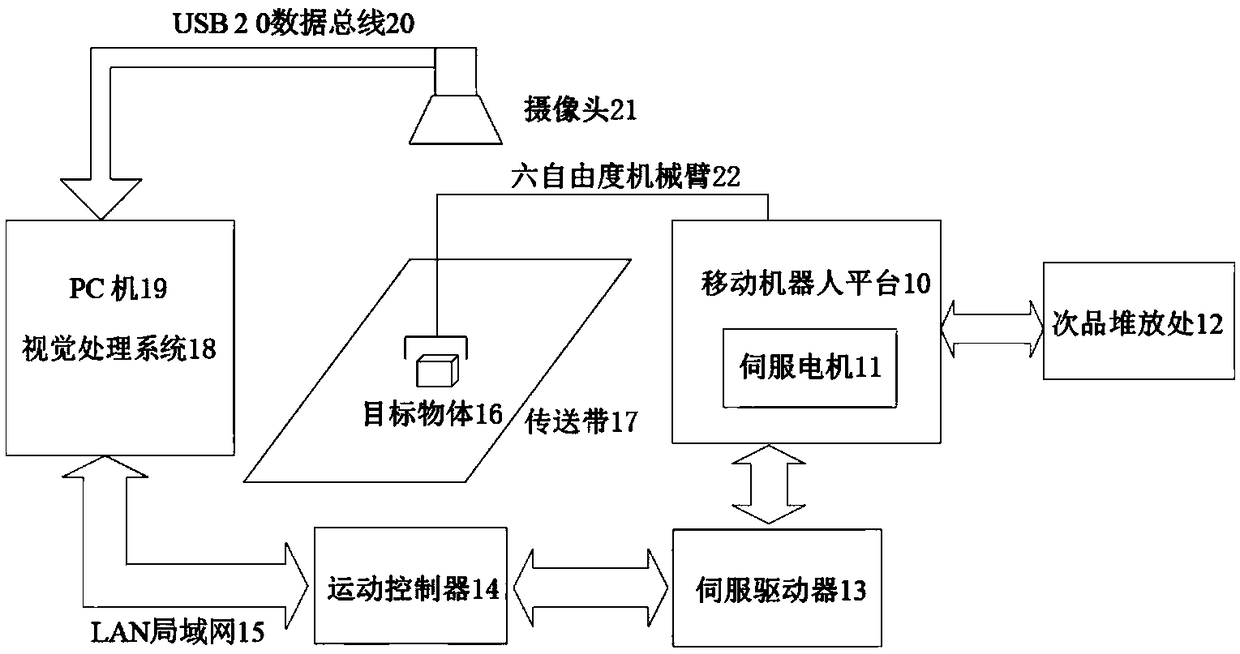

[0017] Such as figure 2 As shown, the mobile sorting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com