VOCs industrial waste gas treatment method

A kind of treatment method, technology of industrial waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

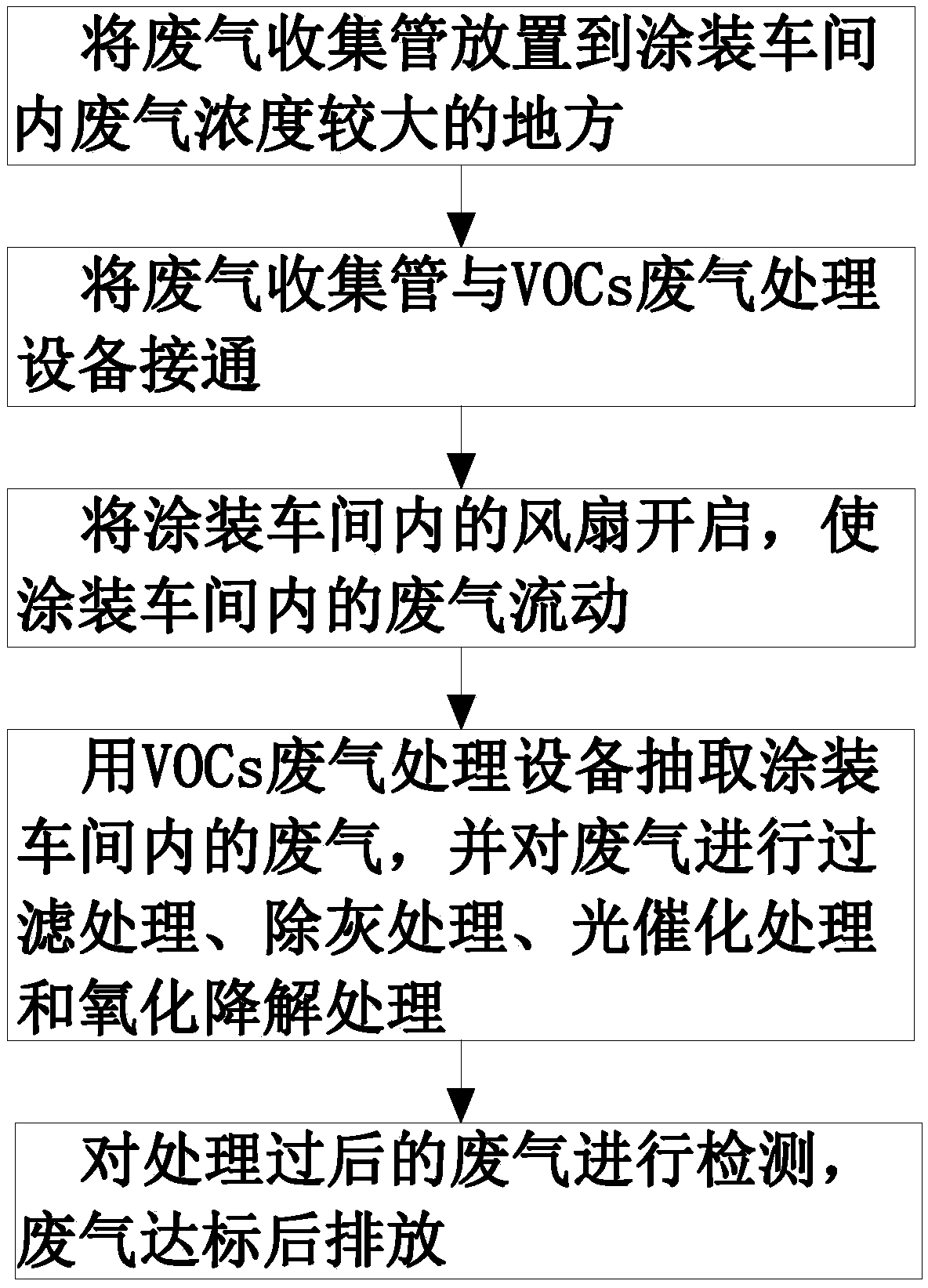

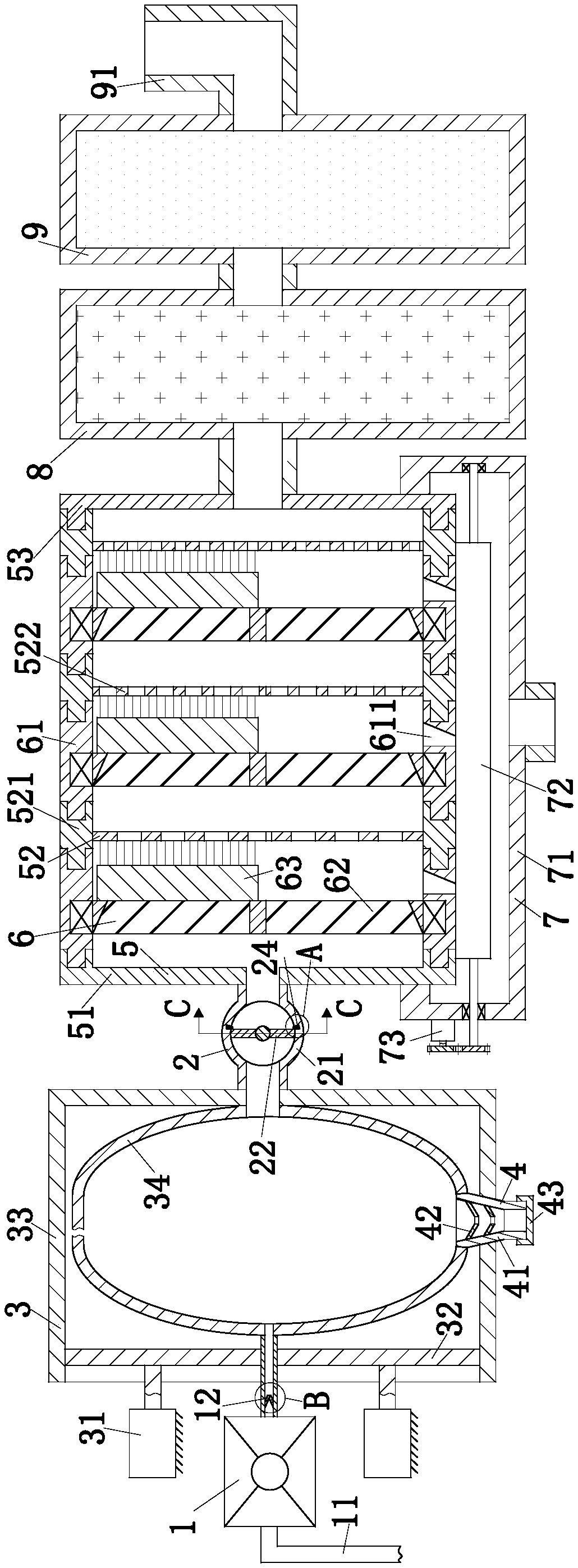

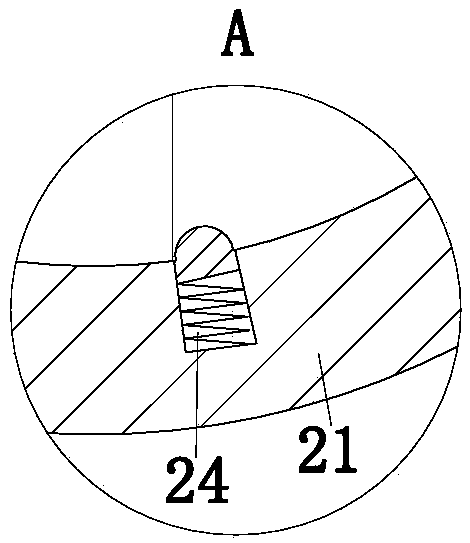

[0031] use Figure 1 to Figure 8 The VOCs exhaust gas treatment method according to one embodiment of the present invention will be described as follows.

[0032] Such as figure 1 , figure 2 and Figure 4 As shown, the specific embodiment of the present invention is a method for treating VOCs industrial waste gas. The method includes the following steps: Step 1: Place the waste gas collection pipe 11 in a place where the concentration of waste gas is relatively high in the painting workshop;

[0033] Step 2: After the waste gas collection pipe 11 is installed in step 1, connect the waste gas collection pipe 11 with the VOCs waste gas treatment equipment;

[0034] Step 3: After connecting the exhaust gas collection pipe 11 and the VOCs exhaust gas treatment equipment in step 2, turn on the fan in the painting workshop to make the exhaust gas in the painting workshop flow;

[0035] Step 4: After turning on the fan in the painting workshop in step 3, use VOCs exhaust gas tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com