Tobacco stem extract, preparation method of ttobacco stem extract and tobacco product

A technology of extracting and tobacco stems, which is applied in the field of tobacco, can solve the problems of complicated process, unrealistic aroma, poor extraction efficiency and extraction effect of tobacco stems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of tobacco stem extract, comprising the following steps:

[0033] a) mixing and heating tobacco stems with water to obtain tobacco stem liquid;

[0034] Mix and activate the complex enzyme with water to obtain an enzyme dispersion;

[0035] The compound enzyme includes cellulase, pectinase, xylanase, protease, amylase and glucoamylase;

[0036] b) mixing and heating the tobacco stem liquid and the enzyme dispersion liquid to obtain reactants;

[0037] c) carrying out alcohol extraction on the reactant to obtain an extract;

[0038] d) reacting the extract with a compound additive to obtain a tobacco stem extract;

[0039] The compound additives include cellulase, xylose, fructose and vitamin C.

[0040] The preparation method provided by the invention can effectively remove the negative odor-absorbing substances in the tobacco stems that affect the taste of smoking, and at the same time, can promote substance transformatio...

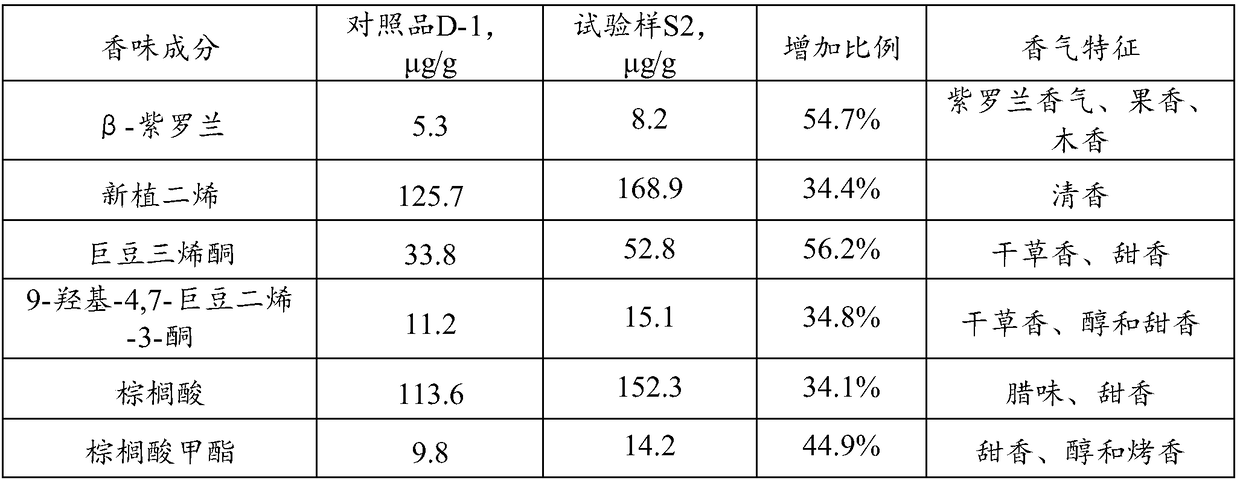

Embodiment 1

[0074] 1.1 Sample preparation

[0075] Add 100g of tobacco stem powder and 750g of purified water into a 1000mL round bottom flask, heat in a water bath at 50°C for 30min to obtain tobacco stem liquid; add 0.1g of cellulase, 0.2g of pectinase, 0.1g of xylanase, protease Add 0.22g, 0.2g of amylase and 0.1g of glucoamylase into 30g of pure water, mix well in a beaker and activate at 25°C for 20min, then transfer to the above round bottom flask, and wash the beaker twice with pure water, each time Use 10g of pure water and transfer the cleaning solution into a round bottom flask, and then react in a water bath at 50°C for 6.5h. After the reaction, add 429g of 95% ethanol to the round bottom flask, and place it in a 90°C water bath for reflux extraction for 1h; bottle; add 400 g of 40% ethanol to the filter residue bottle, reflux extraction in a water bath at 90°C for 1 hour, cool to below 50°C, squeeze and filter with a 200-mesh screen to obtain a filtrate. Combine the two filt...

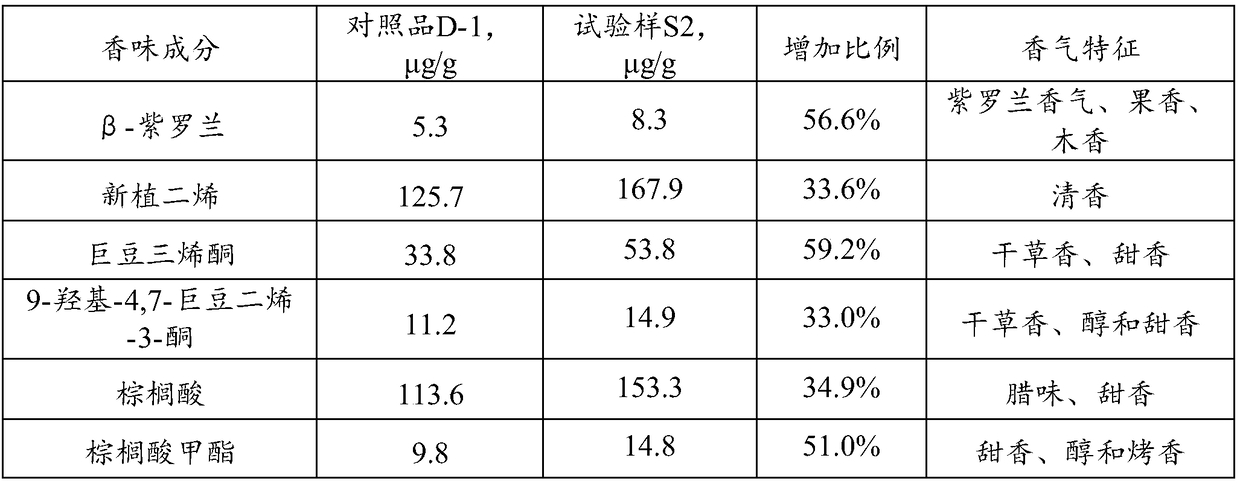

Embodiment 2

[0088] 1.1 Sample preparation

[0089]Add 100g of tobacco stem powder and 700g of purified water into a 1000mL round bottom flask, heat in a water bath at 50°C for 30min to obtain tobacco stem liquid; add 0.08g of cellulase, 0.18g of pectinase, 0.08g of xylanase, protease Add 0.20g, 0.18g of amylase and 0.08g of glucoamylase into 30g of pure water, mix well in the beaker and activate at 25°C for 20min, then transfer to the above round bottom flask, and wash the beaker twice with pure water, each time Use 10g of pure water and transfer the cleaning solution into a round bottom flask, and then react in a water bath at 50°C for 6.5h. After the reaction, add 429g of 95% ethanol to the round bottom flask, and place it in a 90°C water bath for reflux extraction for 1h; bottle; add 400 g of 40% ethanol to the filter residue bottle, reflux extraction in a water bath at 90°C for 1 hour, cool to below 50°C, squeeze and filter with a 200-mesh screen to obtain a filtrate. Combine the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com