An Automatic Modeling Method of Torsional and Tilted Grain Boundaries Based on Heavy Site Lattice Search

An automatic modeling and tilting grain boundary technology, which is applied in instrumentation, computer material science, design optimization/simulation, etc., can solve problems such as lack of models, inability to realize automatic construction, inability to calculate lattice coincidence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is described in detail below in conjunction with embodiment and accompanying drawing.

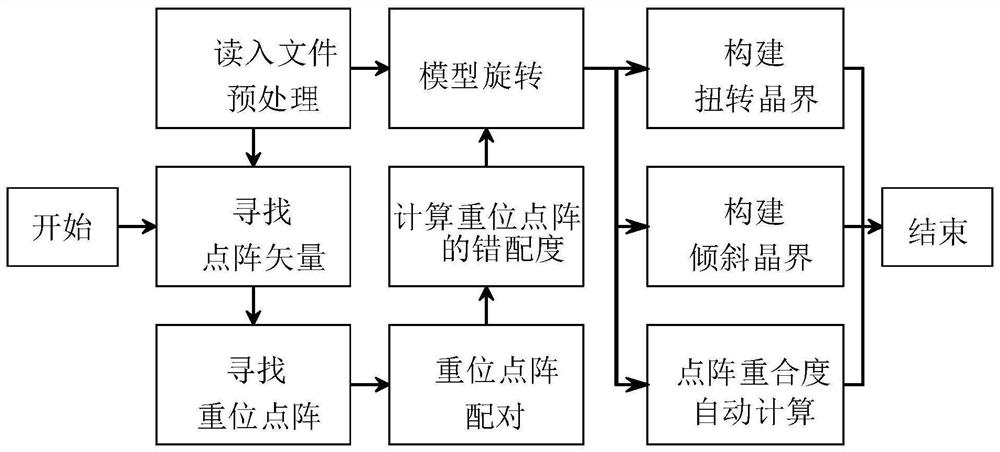

[0053] The present invention provides an automatic modeling method for torsional and inclined grain boundaries based on relocation lattice search, the method flow chart is as follows figure 1 As shown, the specific implementation includes the following steps:

[0054] (1) Read the necessary input files and preprocessing in the modeling process: two lammps data files including the total number of analyzed atoms, the size of the supercell grid, and the coordinates of each atom are defined as file 1 and file 2 respectively. In addition, the user is required to indicate atoms in different environments (for example, two carbon atoms of diamond) in file 1 and file 2. Read user parameters: maximum search range, maximum box size and maximum lattice mismatch. Expands the cell such that the cell size is just larger than the maximum pairing distance entered by the user. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com