Production apparatus and process for fertilizer deodorized at high temperature

A fertilizer and high temperature technology, which is applied in the field of high temperature deodorizing fertilizer production equipment, can solve the problems of inconvenient installation and use, large floor space and high equipment price, and achieve the effects of convenient fertilization, increased yield and improved fruit quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

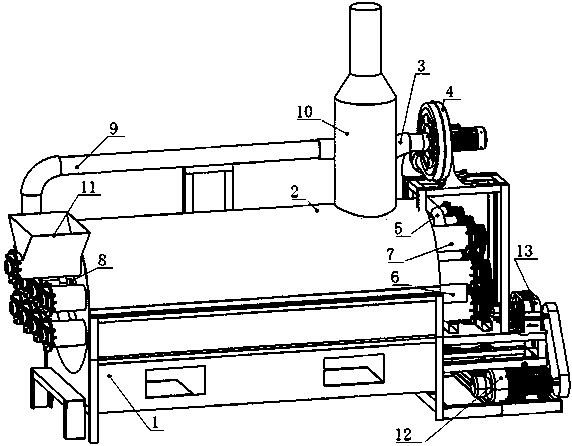

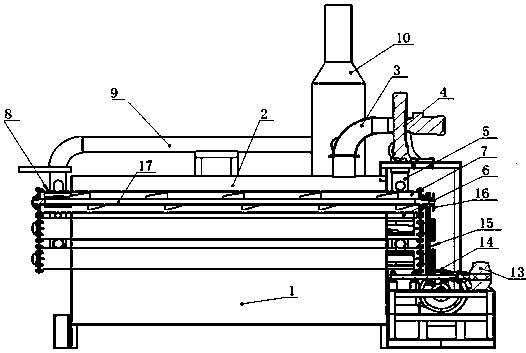

[0022] Embodiment 1, this equipment has power system and drying system.

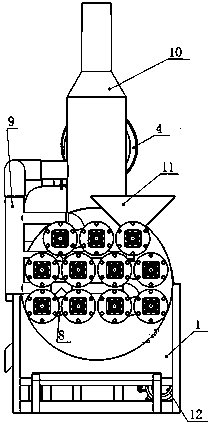

[0023] Composition of the power system: Each heating tube 7 has front and rear openings, which are divided into front opening 18 and rear opening 19. An auger 17 is installed inside the heating tube 7, and the rear end of the auger 17 has an auger sprocket 16, which is connected to the auger sprocket 16. Chain 15, chain 15 is connected sprocket 14, and sprocket 14 is on the output shaft of transmission 13, and transmission 13 is driven by motor 12. The heating pipes 7 are connected in series end to end one by one, prolonging the tube length of the heating pipes, so as to extend the stirring, dehydration and drying time of feces in the pipes.

[0024] The basic overview of the drying system: the heat source enters the furnace 1 for heating, and the furnace blower 21 blasts the furnace 1 to increase oxygen. The upper part of the furnace 1 is arranged with a plurality of heating tubes 7, and each heating tu...

Embodiment 2

[0025] Embodiment 2, the process flow of the present invention is that the feces are sent to the steam furnace through pipelines, cooked and sterilized in the high-temperature exhaust gas flue above 100°C, and the fermentation is accelerated to remove the odor. After the feces are dehydrated, they become dry feces fertilizers. In this way, the whole process of manure disinfection, deodorization, and processing into fertilizer is completed, achieving the purpose of "turning harm into benefit", and it is convenient for management and transportation. Feces are poured into the heating pipe 7 from the feed hopper 11, pass through the front opening 18, and are twisted by the auger 17 to move to the rear opening 19, and enter the rear opening 19 of the next heating pipe 7 through the rear connector 6 of the heating pipe. The auger 17 is pushed to the front opening 18 of the heated pipe 7, and repeats this back and forth. Since the heated pipe 7 is connected to the front opening of a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com