Inkjet printing system and method for panel manufacturing process

An inkjet printing and inkjet printing head technology, applied in the field of panel manufacturing, can solve the problems of uneven film thickness, reduction of droplets in pixels where the organic light-emitting material is dropped, and inability to perform timely monitoring, etc., so as to improve detection efficiency, Avoid bad batch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

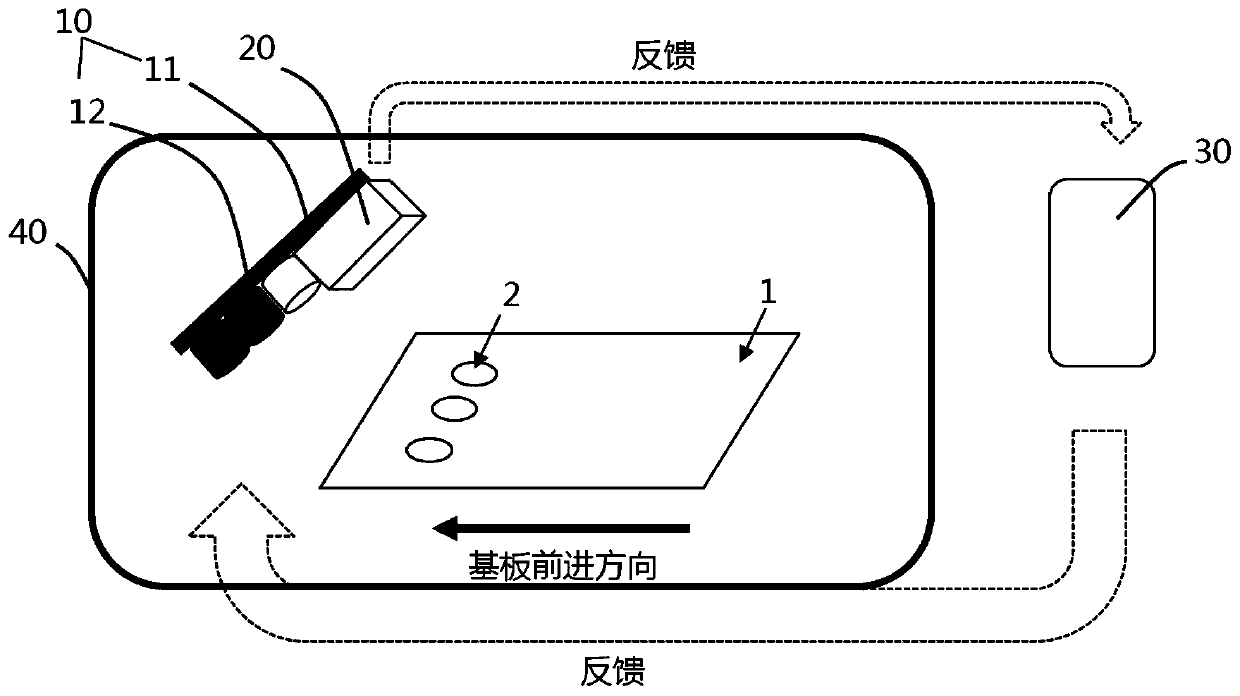

[0026] refer to figure 1 , the inkjet printing system of this embodiment can be mainly used in the panel process to spray organic light-emitting materials on the substrate 1 to form pixel units, including an inkjet printing head 10, a detection module 20, a main control unit 30 and a printing chamber 40, The printing chamber 40 adopts a closed structure. The inkjet printing head 10 and the detection module 20 are all arranged in the printing chamber 40. The inkjet printing head 10 is used to eject ink droplets toward the substrate 1 placed in the printing chamber 40 to The film layer 2 is formed on the surface of the substrate 1, and the detection module 20 is used to obtain the thickness data of various regions on the surface of the film layer 2 and feed it back to the main control unit 30. The main control unit 30 is used to Analyzing the film thickness difference on the surface of the film layer 2 , and correcting the number of ink droplets ejected by the inkjet printing he...

Embodiment 2

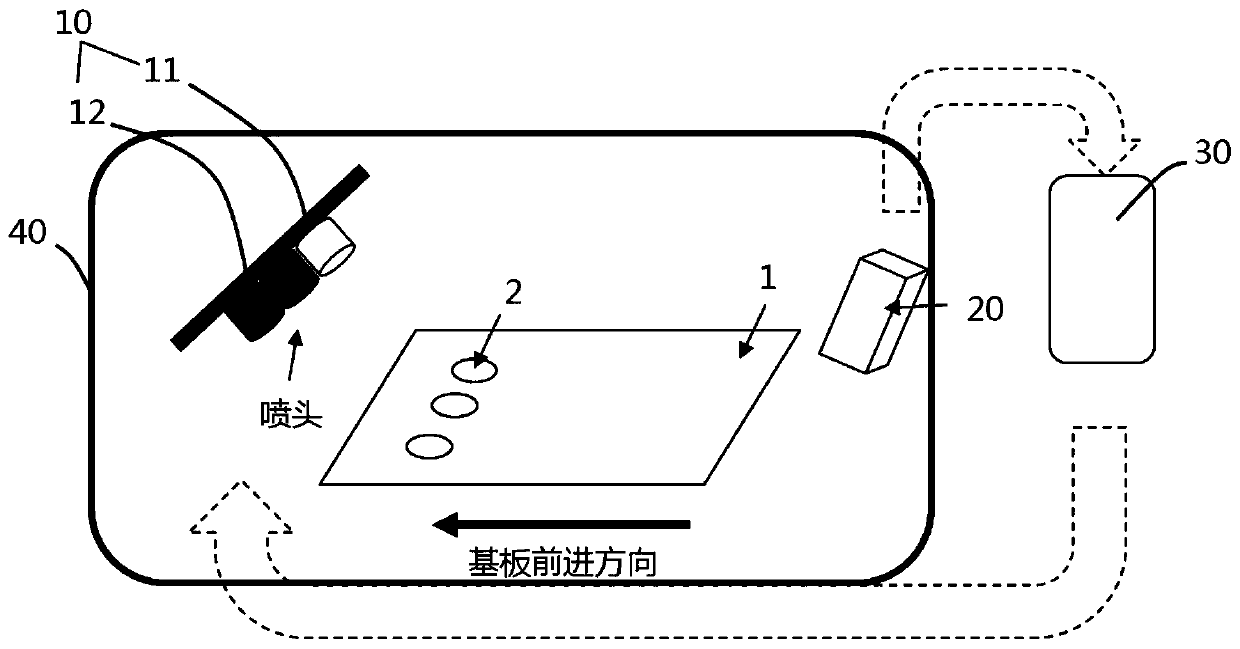

[0040] like image 3 As shown, different from Embodiment 1, the detection module 20 of this embodiment is set separately from the inkjet print head 10, and the inkjet printing system not only includes a conveying mechanism for conveying the substrate 1 from upstream to downstream, but also includes The reverse conveying mechanism for reversely conveying the substrate upstream, the detection module 20 is located upstream relative to the inkjet print head 10 , and is located at the initial position of the substrate.

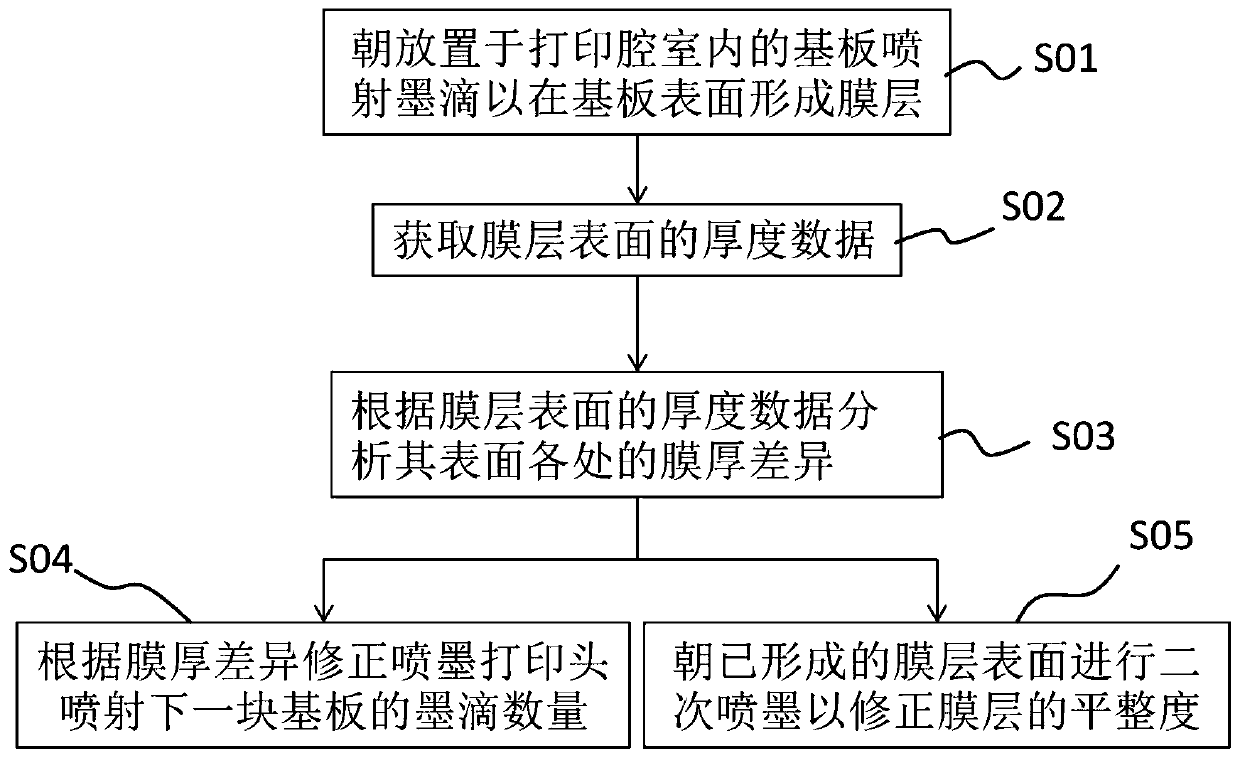

[0041] The inkjet printing method of the present embodiment mainly includes:

[0042] S01, jetting ink droplets toward the substrate 1 placed in the printing chamber 40 to form a film layer 2 on the surface of the substrate 1;

[0043] S02, obtaining the thickness data of the surface of the film layer 2;

[0044] S03, according to the thickness data on the surface of the film layer 2, analyze the film thickness difference at various places on the surface of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com