Corrugated board full-automatic cutting system for high precision instrument

A technology of corrugated cardboard and cutting system, which is applied in the direction of paper/cardboard containers, containers, papermaking, etc. It can solve the problems of unfavorable storage and transportation, inability to automatically feed cardboard, integrated cutting, high cost, etc., and achieve the effect of filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

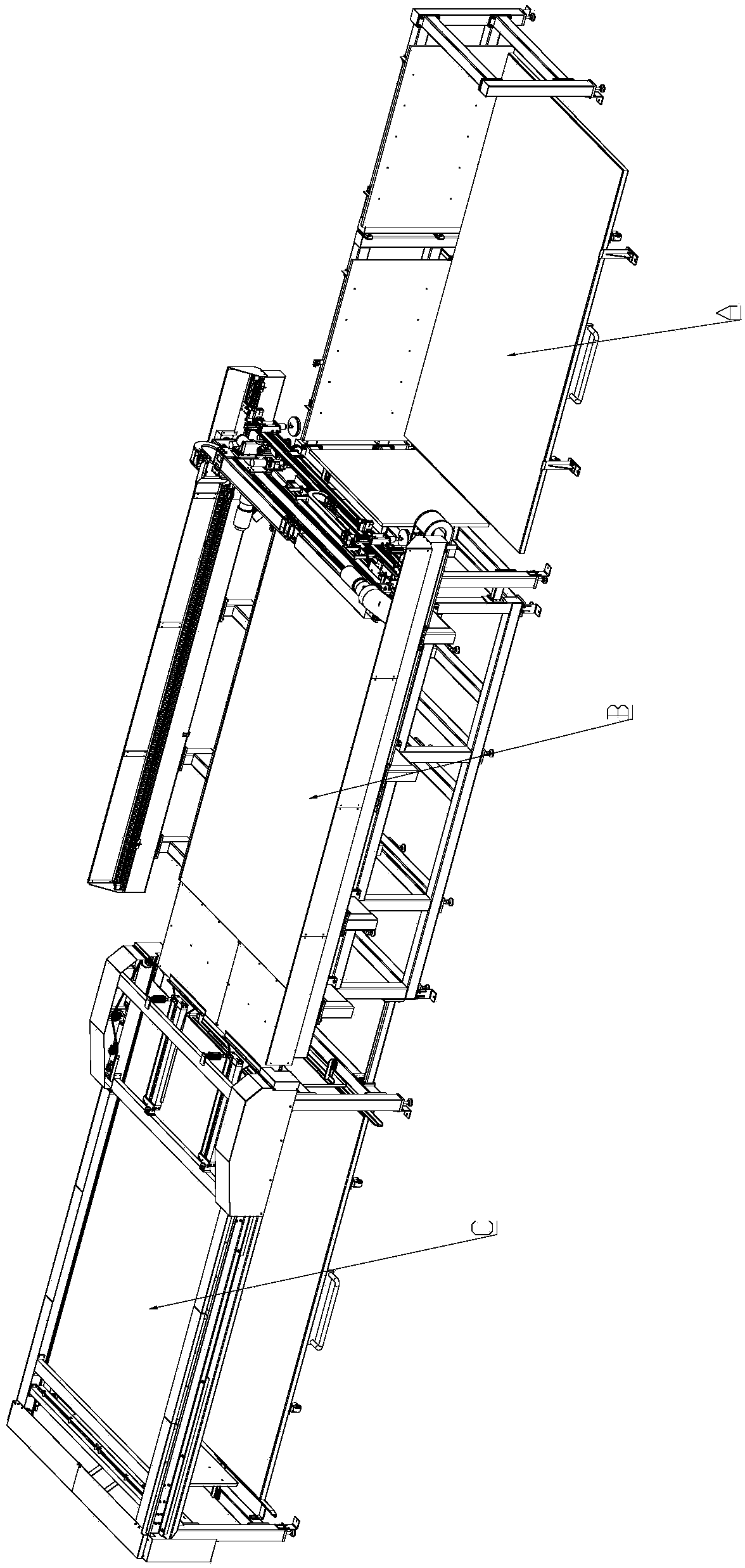

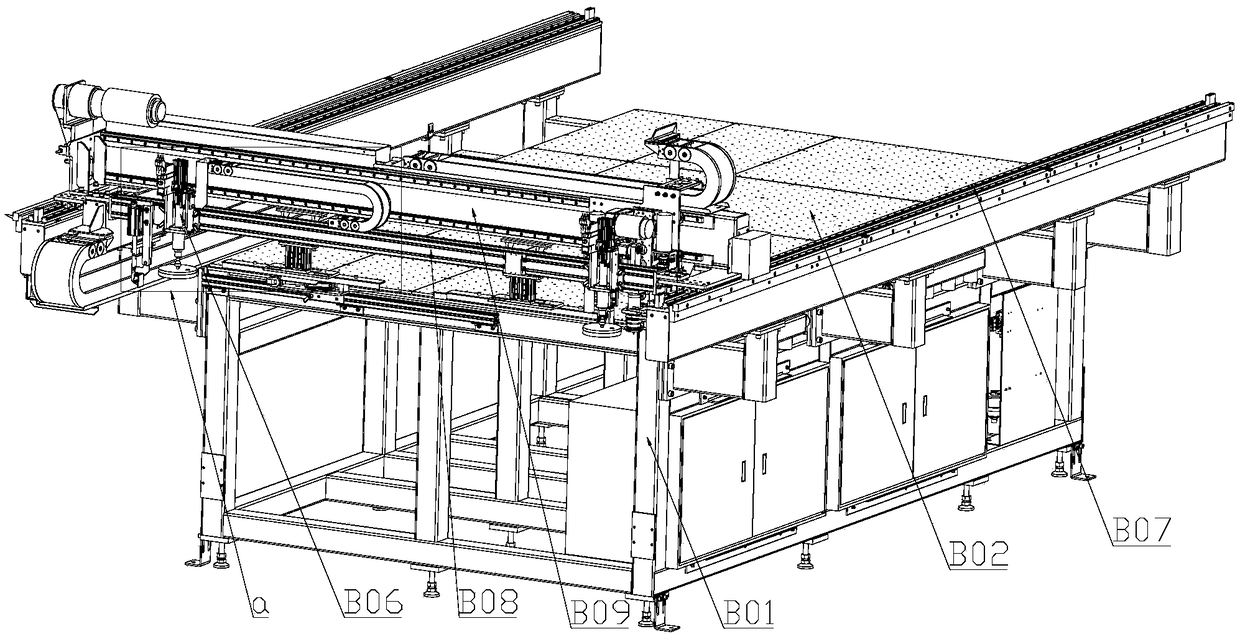

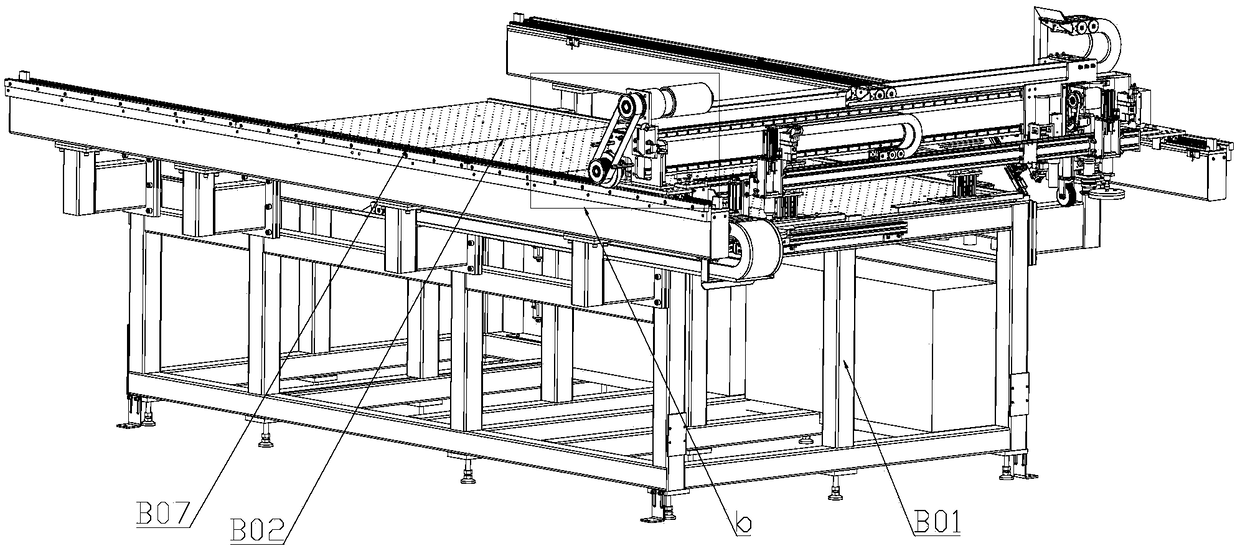

[0038] Such as Figure 1-3 , 23-24, a fully automatic cutting system for corrugated cardboard for high-precision instruments, including a first movable lifting table A, a cutting device B and an unloading device C arranged sequentially along the same straight line;

[0039] Wherein the cutting device B comprises a cutting support frame B01, the cutting support frame B01 is provided with a cutting table B02, the cutting support frame B01 is provided with an x-direction linear sliding device B07 along the length direction of the cutting table B02, and the x-direction linear sliding device B07 is The first y-direction linear slide device B08 and the second y-direction linear slide device B09 are arranged along the width direction of the cutting table B02. The first y-direction linear slide device B08 is close to the first movable lifting platform A, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com