Self-cleaning numerical control machine tool

A CNC machine tool, self-cleaning technology, applied in the direction of presses, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of low cleaning efficiency, inconvenient waste disposal, high frequency of waste cleaning, etc., to achieve the degree of automation High, improve the waste collection capacity, reduce the effect of daily cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

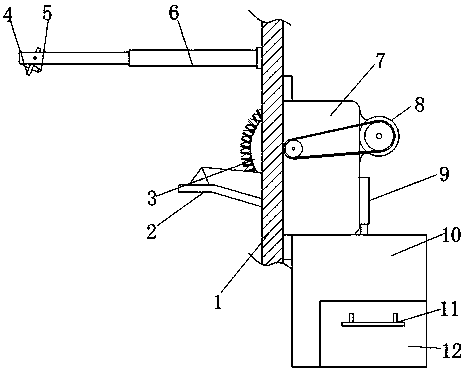

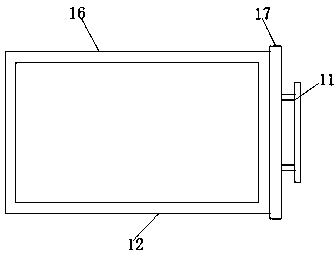

[0019] refer to Figure 1-3 , a self-cleaning numerically controlled machine tool, comprising a machine tool housing 1, a first housing 7 fixed to the outer wall of one side of the machine tool housing 1 by bolts, and a motor 8 fixed to the side wall of the first housing 7 by bolts, the machine tool housing 1. There is a square hole on the side wall close to the first housing 7. The inner wall of the first housing 7 is movably connected to the rubber roller 3 through the bearing. The side wall of the rubber roller 3 is clamped with nylon bristles distributed equidistantly. 1 The outer wall of the side away from the first housing 7 is fixed with a slope plate 2 by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com